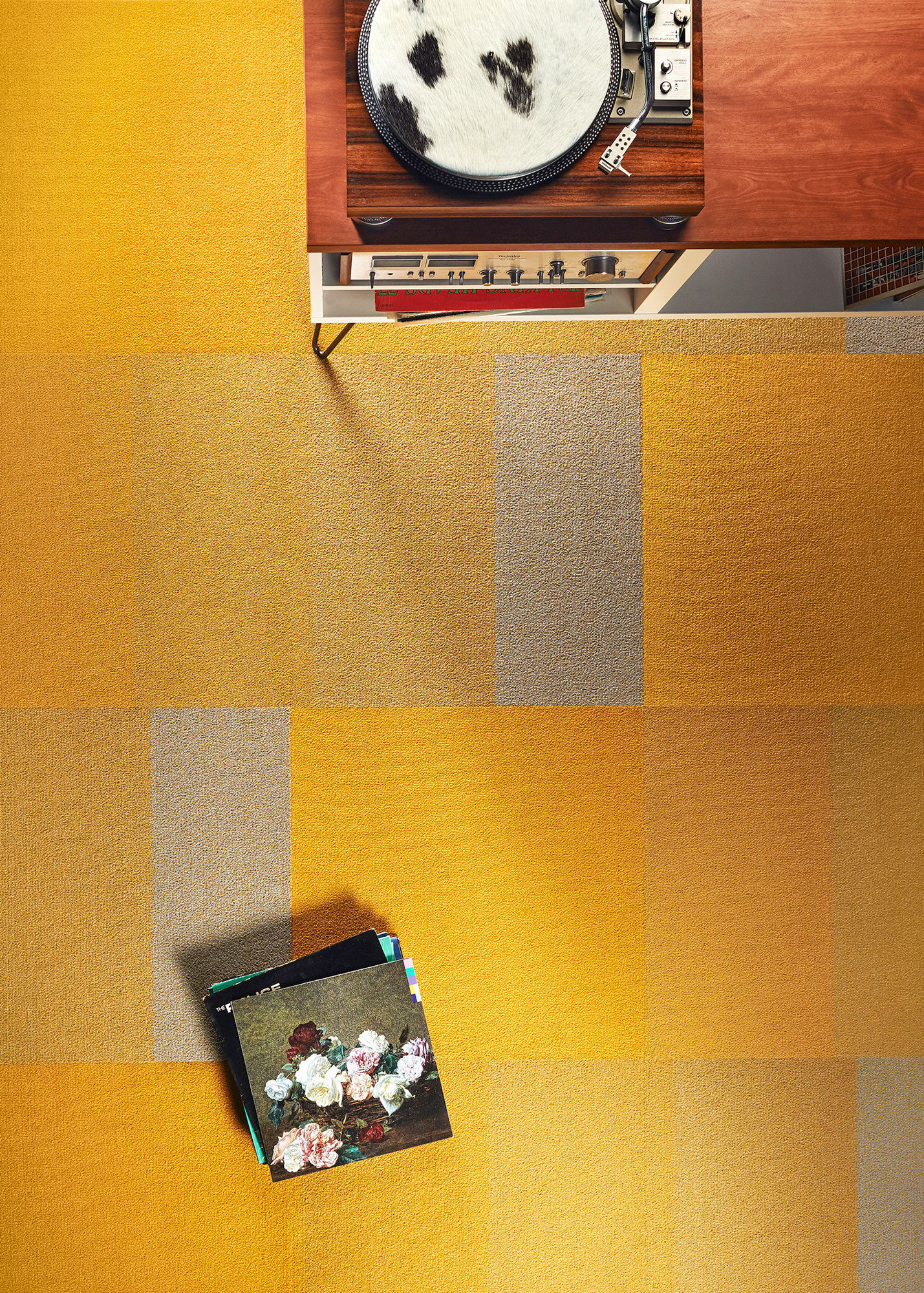

[Photo: Courtesy of Bentley Mills]

“We don’t want to wait for something to happen and then catch up with the train. We’re always trying to find new ways to keep the market exciting. We want to make sure we’re putting the best product out there.”

Bentley Mills has always been ahead of the trends, from design to sustainability. Most recently, the largest commercial carpet manufacturer in California has upped its green game, not only focusing on its own energy efficiency and building performance, but adding transparency and materials to the mix at a high level.

While there’s plenty to be proud of already, the year 2017 has even more exciting developments ahead, according to David Turkes, Bentley’s sustainability engagement specialist. “We don’t want to wait for something to happen and then catch up with the train. We’re always trying to find new ways to keep the market exciting. We want to make sure we’re putting the best product out there,” he says.

Bentley was the first manufacturing facility in the U.S. to be LEED certified (it received Silver certification in 2007 and Gold in 2013), and the company shows no signs of slowing down, as it commits to recertifications and continues to push the envelope when it comes to making the best and boldest carpet tiles. “People want to know what’s in their products,” Turkes says. “Transparency and disclosure has taken hold of the sustainability message, especially in the flooring industry.”

[Photo: Courtesy of Bentley Mills]

CEO Ralph Grogan has been in the business for roughly 30 years, having worked with Tandus Flooring and Lees Carpets prior to joining Bentley in 2013. Needless to say, he knows a good company when he sees one. Grogan now leads more than 300 employees worldwide. “Bentley had always been one of those iconic brands in the industry. The history of the brand was very, very strong,” he says. In the years before joining Bentley, Grogan paid close attention to how the company was run when he noticed an opportunity to better nurture the brand with the help of the company’s private equity partner. “We really focused on product,” he says, adding that the new team immediately got to work introducing even more sustainable products and verifying its efforts.

“From a sustainable standpoint, Bentley had always manufactured in California, so from a water and air standpoint, it had always been very environmentally friendly,” Grogan says. But they also wanted to verify that. In Grogan’s first year, all of Bentley’s products were Cradle to Cradle certified. “To have an outside agency come in and evaluate everything we’re doing—from the raw materials we put in the product to how we make the product—that was very important to us.”

[Photo: Courtesy of Bentley Mills]

Better, Brighter Products

It doesn’t hurt that Bentley’s carpet tiles are also beautiful. “Going back to 1979, the people who founded Bentley founded it on unique looking products,” Grogan says. While some of that emphasis fell away before Grogan came on board, Bentley began to kick things up a notch in last five years. “What we’ve done in the four-and-a-half years I’ve been here is to really get back to our product roots. We try to introduce a new collection every month.” That’s a lot of collections, even for a company that’s bigger than Bentley.

By the same token, Bentley has also invested heavily in carpet tile technology. Less than five years ago, the company’s products were about 75% broadloom and 25% carpet tile, but now it’s the reverse. “We knew we needed to invest in tufting equipment and carpet tile technology. We worked very closely with Cradle to Cradle to make sure the line we picked out and the technology we picked out would be outstanding, from what goes into the product and from a recycling standpoint at the end of the product’s life.”

Over the past few years, Bentley has also invested in colorpoint technology, which Grogan calls the greatest technology out today, as it has truly taken the company’s colors and patterns to the next level. Bentley introduced several new products with the colorpoint technology at the 2016 and 2017 NeoCon. The company recently took home the Silver and Editors’ Choice awards for carpet in the broadloom category at NeoCon 2017 for its Outskirts Collection and Night Vision, respectively.

[Photo: Courtesy of Bentley Mills]

Certifiable Greatness

Proving its commitment to transparency, Bentley is currently working toward re-certifications for Cradle to Cradle, LEED-EB Gold, and its Platinum NSF 140 certification. Certifications like NSF 140 look at where ingredients come from and examine the life cycle of the carpet and end uses, asking questions like, “Can this be recycled?”

Bentley was “green” long before green was “cool,” or even mandated, though. Part of that is because of its home state’s strict sustainability standards. “California is always wanting to push forward,” Turkes says. “They’re always trying to be one step ahead. And we always want to be the pioneers. It’s something we pride ourselves on.”

Grogan says it all goes back to the company’s founding in 1979. The commitment to making the best, healthiest products has never changed. “Just to manufacture in California is different than manufacturing in other places. The water regulations, the air regulations, there are so many things you have to do in California that you don’t do in a lot of the other states. This has been the Bentley culture from day one.” Grogan says it’s second nature for the West Coast company, and that’s not about to change. “We’re proud of the way we make products,” he says. “We’ve got a lot of people here who have been doing it the right way for a long time.”

[Photo: Courtesy of Bentley Mills]

Communication is Key

An important part of making the best products is understanding why you’re making them that way, though. Turkes says communicating the mission and even new certifications company-wide makes a huge difference in maintaining a positive company culture. First, Turkes spends a lot of time working with the sales team to make sure they have the tools they need to succeed when talking to clients—to truly explain what makes these products so special and to be able to talk about them in layperson’s terms.

Turkes says it’s also important to make sure the many certifications are communicated and understood. After all, if you’re going to make the effort to be recognized at such high levels, you want to make sure everyone understands what that means, including everyone on the manufacturing floor.

The company also values feedback, and things like employee surveys are proof. Whenever a new program is implemented, like, say, Declare Labels, Turkes and the marketing team craft a message for employees and ask for questions. Then, he waits for about a week to see what responses he gets. But he also takes it one step further, asking, “Who else might have the same question?” If one sales rep has asked, “What does this mean?” another sales rep likely has the same question. Turkes follows up with cold calls to other reps to see if they have similar questions and, most often, they do. It’s all about being proactive. “Feedback is important,” he says. “If you don’t have people who buy into what you’re doing 100%, you’re losing your message.

The company also frequently gauges its employees’ happiness, like with a recent LEED occupant comfort survey, inquiring about everything from lighting to noise in the plant. Almost all of the employees responded, as Turkes personally handed out the survey, and a raffle encouraged even more participation. “We want to make sure our employees are as comfortable as possible,” Turkes says.

[Photo: Courtesy of Bentley Mills]

Best in Class

It’s not just Bentley’s own products that are setting the bar. The company, which has more than 500,000 square feet of manufacturing facilities and corporate offices, is also continually improving the way it operates. Currently, the company is in the midst of a huge project that will put it at the forefront of energy operations in the manufacturing industry. Grogan says Bentley is making a real commitment to solar in its facilities, citing the project Turkes was immersed in in early summer. Bentley already has one of the country’s first privately owned, industrial solar power arrays that provide some of the energy used for manufacturing. Currently, 100% of Bentley’s electrical energy requirements are made renewable through the purchase of Green-e certified renewable energy certificates derived from wind and biomass and from on-site generation from the solar array. “A very significant part of our power is going to come from solar energy,” Grogan says. “It’s not a pipedream. It’s in our next capital expenditure forecast. We’re very excited about it becoming a reality very, very soon.”

[Photo: Courtesy of Bentley Mills]

Efforts like these are a continuation of a longstanding legacy of doing good. Since 1994, Bentley has successfully diverted more than 250 million pounds of carpet material from North American landfills. In 2015, Bentley was recognized by the Department of Energy for meeting its energy efficiency targets six years ahead of schedule. Late last year, the company joined Mindful Materials, a database used by designers to locate certifications and declarations. And earlier this year, Bentley joined the Declare Label program.

Once a month the company also does a “dumpster dive,” sorting through everything that’s been thrown out to see if it could be recycled. It’s part of why Bentley has a 97% waste diversion rate. “We’re making sure no one inadvertently throwing away a plastic bottle that could be recycled,” Grogan says, adding that Bentley makes it a fun sort of competition between departments. “I’ve never worked at a place where everyone is so conscientious of what everyone is doing. I’m sitting at my desk and just out of habit I’ll throw something in the regular trash and I’m like, ‘Oops, I don’t want to be the one caught in the Dumpster Dive for having something in there. It makes us all very conscious of what we’re doing.”