When Peter Strugatz and Miranda Magagnini purchased Great Harbor Design in 2003, it was $5 million in debt after failing to engineer a new sustainable countertop from glass and concrete. But the entrepreneurs had a vision, and with the help of Dr. Weihua Jin, a cementitious expert from Polytechnic Institute of New York University, they created not just a sustainable surface but an entirely sustainable operation. Today the business, renamed IceStone, LLC, has 50 employees, has grown its annual revenue by double digits every year since 2003, and has earned a cult following among architects and interior designers.

vision/

For Strugatz and Magagnini, sustainability was about more than the product. IceStone’s line of slabs, which can be fabricated into countertops, flooring, backsplashes, and interior wall finishes, are certainly sustainable: they’re manufactured in the United States from three raw materials (recycled glass, concrete, and natural pigment) without any toxins such as resins or dyes, and they can help a project obtain up to eight LEED points. But the founders were also determined to be socially sustainable. “We call it our triple-bottom-line vision,” president and CEO Michelle Gibson says. “Peter and Miranda wanted to operate a profitable business producing an environmentally sound product while treating employees with respect by offering them a living wage in New York City.”

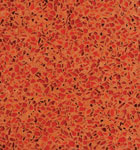

Three of IceStone's popular styles (from left): Denim Moss, Amber Pearl, and Persimmon

sustainability/

IceStone is environmentally conscious on a number of levels, Gibson says. Because it is manufactured, it avoids mining and quarrying—which often involves relocating indigenous people, operating emission-producing machinery, and releasing toxic chemicals into nearby rivers, streams, and aquifers—and eliminates the use of child labor, which is prevalent in mines throughout developing countries. Because IceStone is manufactured in the United States and generally shipped to North American consumers, it has a limited carbon footprint. And because it uses recycled glass, it reduces waste. “Thus far, the company [has] used 10 million pounds of glass that would otherwise have gone straight to the landfill,” Gibson says.

social responsibility/

social responsibility/

Forty percent of IceStone’s employees are Tibetan refugees, and all are paid well above New York’s minimum wage, which is $7.25 per hour. “It’s difficult to live in a high-cost area such as New York on minimum wage, so entry-level pay for our production workers is a minimum of $10 an hour,” Gibson says. “Because we haven’t yielded to pressure to cut labor costs, it’s been harder to achieve profitability, but we’ve taken the hit in that and are determined to focus on that going forward because we know that what we’re doing is bigger than the product—it’s about redefining corporate responsibility and bringing manufacturing back to America.”

third-party certification/

IceStone is the only durable surface to be certified Gold under the Cradle to Cradle Certified program. The program rigorously assesses the design of a product as well as the practices employed in manufacturing it. “It looks at the entire supply chain—not just the four walls of the factory—to evaluate environmental and social impact,” says Gibson, who notes that the company offsets 100 percent of its energy use with renewable energy credits and recycles 85 percent of the water used in production, saving nearly five million gallons annually.

customers/

According to Gibson, IceStone’s “go-to market” is architects and interior designers, who specify the product on a range of projects, from small residential spaces to large commercial installations. IceStone is also sold through stone distributors and, in some cases, large fabricators and installers. “The product is becoming iconic in a small segment of North America,” Gibson says. “People just love it because of the style, durability, and sustainability, and we’ve been placed in the Bill and Melinda Gates Foundation, the Empire State Building, and Bank of America Tower in New York City.”