Anew car. A new carpet. That pressed wood dresser in your urban loft. They smell so fresh and so clean. And they are—sort of. But that characteristic scent they emit derives from something less physiologically pleasing: volatile organic compounds (VOCs).

VOCs are carbon-based chemicals that evaporate quickly at room temperature and contribute to poor indoor air quality and smog. Studies by the Environmental Protection Agency (EPA) and other researchers have found that VOCs are common in indoor environments and that their levels may be two to 1,000 times higher than outdoors. Add up the hours people spend indoors: sleeping, eating, working in offices or at school—about 90%, according to 1989 EPA report to Congress—and VOC exposure becomes a genuine cause for concern, among not just environmental advocacy groups and health agencies, but also building contractors, architects, and manufacturers.

“Indoor air quality is always going to be at the forefront of what we do,” says Amy Woodard, product steward and regulatory compliance officer at Tremco, a Cleveland-based supplier of roofing, sealant, weatherproofing, and passive fire control materials for commercial and residential construction and industrial applications. “It is important to protect the health of the occupants of any building being built.”

Founded in 1928 and employing more than 2,000 people, Tremco specializes in products that reduce air flow in and out of buildings: urethane and silicone sealants, deck coatings, waterproofing membranes, window glazings, and other specialty coating systems. Minimizing thermal loss is good for the environment and reduces energy bills. A win-win, as they say.

Yet, when it comes to minimizing indoor air pollution, sealants pose particular challenges. While chemical emissions from VOCs may come from all manner of things—building products, furnishings and furniture, flooring, cabinetry, paint, and textiles—sealants, which are typically solvent-based, are among the worst culprits. Depending on the type of pollutant, its concentration, the duration of exposure, and the individual sensitivities of those exposed, VOC emissions from these materials can lead to immediate health effects, such as headaches, fatigue, and allergic reactions, and more serious health problems, including respiratory problems and cancer.

Woodard works closely with her research and development team and product specialists from UL Environment to ensure Tremco products do not pose such health risks. A total of 64 Tremco products meet the GREENGUARD Gold Certification standard, UL Environment’s most rigorous standard for low indoor air emissions of VOCs, which complies with California Department of Public Health emissions guidelines for schools and health care buildings.

GREENGUARD Gold Certification also ensures Tremco’s products meet regional and state regulations, such as those adopted from the stringent South Coast Air Quality Management District of Los Angeles, and indoor air quality guidelines that require third party product testing and evaluation such as the U.S. Green Building Council’s LEED rating system. “We look at all of these factors when we develop our products. They help drive R&D formulation to make sure we stay competitive in the market,” Woodard says.

Initial certification testing for a product family runs in the ballpark of $10,000, and recertification, which typically takes place every three years, costs between $1,000–1,500. Once certified, companies (like Tremco) can display the GREENGUARD logo on their website and marketing materials to promote the sustainability and safety of their products.

Woodard said the partnership between Tremco and UL Environment has been extremely beneficial, not only by helping Tremco fulfill client demand for low-emitting sealants and waterproofing materials, but also by familiarizing her with the evolving codes, requirements, and certification protocols of a complex industry. “They have been incredibly helpful to me as a new employee in getting to understand their process and services and what they mean,” Woodard says.

Sustainable Solutions

Tremco builds bridges between adjacent but often unconnected building elements—a both logical and necessary set of offerings

FOR WHEN YOU NEED A ONE-STOP-SHOP…

PRODUCT: Proglaze ETA

FUNCTION: Proglaze ETA is a transition assembly composed of pre-engineered, finished aluminum and silicone materials that comes in handy when builders are looking at irregular window geometries or when inspectors need to see through the gasket to verify that a project has the proper amount of sealant (thanks to its translucent silicone material). It renders Tremco a convenient, one-stop-stop for designers and builders.

IN PRACTICE: The design and construction teams working on the Naval Hospital Replacement Project at Camp Pendleton needed assurance that the construction process could not only meet government speculations but also demonstrate performance throughout required warranties and beyond, which Proglaze ETA provided. “While it’s our desire to use small business in our subcontractor selection, it’s a great benefit for a complete product assembly to be provided by a sole source,” says Craig Winters, CQ Superintendent on the Clark/McCarthy Joint Venture on the project. “If you provide more scope to a manufacturer and have a problem or a question, you only have to go to one source for assistance. There’s less confusion, less ambiguity, and you avoid overlap of products or solutions.”

FOR WHEN YOU WANT TO AVOID CRACKS AND YELLOWING FROM THE SUN …

PRODUCT: Dymonic 100

FUNCTION: This highly versatile sealant has the unique ability to adhere to damp and green concrete. It’s also paintable and won’t crack, craze, or yellow under extreme UV exposure. An added bonus? It’s jet-fuel resistance. Even after a year, Dynomic 100 extended 100% when tested in the lab.

IN PRACTICE: This sealant withstood UV radiation and weathering during rigorous testing, meaning the likelihood that it will maintain its integrity and provide long-lasting protection against air and moisture infiltration without cracks is huge.

FOR WHEN YOU’RE BATTLING ENERGY LOSS DUE TO WEATHER …

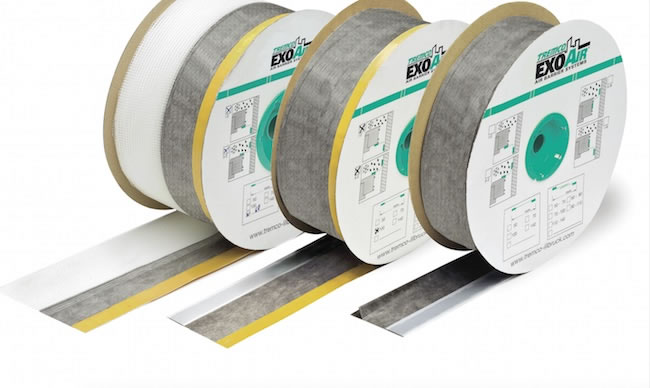

PRODUCT: ExoAir T3 Solutions

FUNCTION: Throughout the seasons, energy moves through the walls—be it cool air lost to the outside in the summer or warm air in the winter. In the winter, the 50% average heat loss experienced in traditional buildings can be totally avoided with this sealant (which solves issues of varying window types, size, and geometry and plane changes when surfaces bond).

IN PRACTICE: Multi-family housing projects benefit most from this solution, as an airtight and thermal bridge-free envelope ensures heat (and ensures that energy generated in a building isn’t wasted). Plus, these types of projects also must take acoustical, firestopping, and air-sealing requirements into consideration. This holistic approach to wall-system design also surpassed even Passive House standards when tested, leaving sufficient room for anything that might come up during actual construction conditions.