Sunbrella’s fabric architecture takes beautiful spaces and makes them even better.

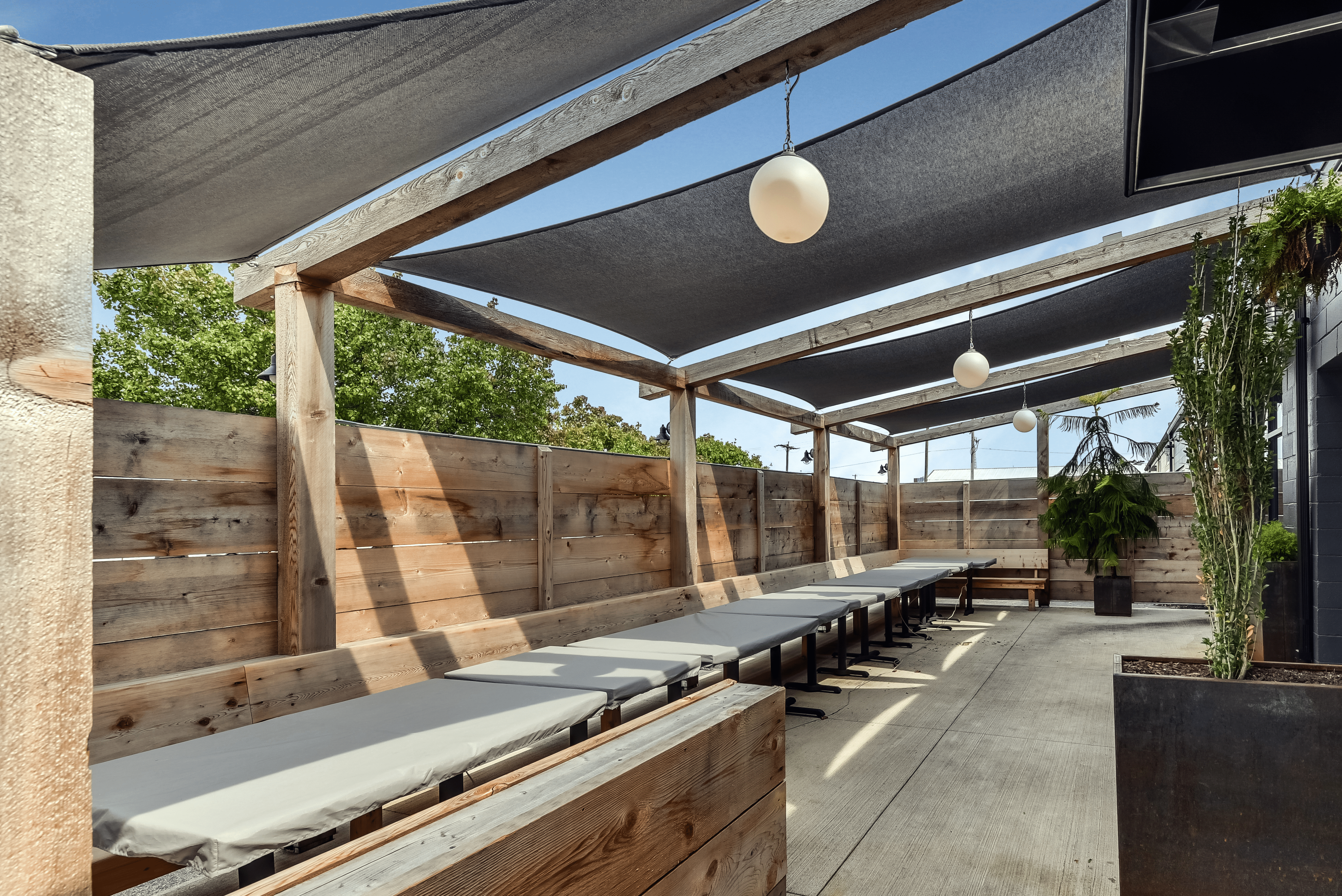

Sunbrella helped to transform one Columbus, Ohio, eatery. [Photo: Courtesy of Sunbrella]

Sometimes people just want to sit outside, enjoy a drink and a lazy dinner, and soak up the sun. But not too much sun. And maybe it starts to sprinkle. So it’d be really nice to have a little protection overhead.

Sunbrella, a leading manufacturer of high-end performance fabrics like those used in shade sails, has the perfect solution to all this and more—delivering durable, flexible designs in compelling styles, like Sunbrella Contour, recently used for a custom solution at Watershed Kitchen & Bar. “This bar is in an area that is very hip and up-and-coming, and the owners are young, creative, and innovative, so it was fun to enter this atmosphere and have such a ‘hit the nail on the head’ success,” says Tim Kellogg, a fabricator who has worked on multiple projects using Sunbrella shade fabrics.

Kellogg installed shade sails using Sunbrella fabrics at the Columbus, Ohio, restaurant and distillery in spring 2017. He says the restaurant owner not only wanted to provide shade for the outdoor seating area but also to cool the eating space inside. Sunbrella’s unique design exceeded expectations and ultimately made the customers comfortable, too. “It could not have turned out better,” he says. The installation also extended the usable patio area.

Sunbrella was able to provide shade for the outdoor seating area as well as cool the eating space inside. [Photo: Courtesy of Sunbrella]

Taking Risks

Sunbrella is always up for a challenge, says Vince Hankins, Sunbrella’s industrial business manager, who’s been with the global manufacturer for more than 25 years. He says the company seeks to work with true innovators who want to break the mold when it comes to design, durability, flexibility, and protection. “This is the community that’s really driving the innovation and design train into the future, and we want to make sure shading is part of that,” he says.

Kellogg says the biggest challenge in the Watershed project was to convince the client to go custom, choosing a high-quality, professionally designed fabric instead of a cheaper standard design the owner would have to install himself. Fortunately, it was worth the investment, especially as Sunbrella’s high-performance product was so attractive, matching the rest of the restaurant’s ambience. “The shade sails were at the front of the restaurant, just to the left of the front door, and the appearance of the shade sails was part of every customer’s first impression,” Kellogg says.

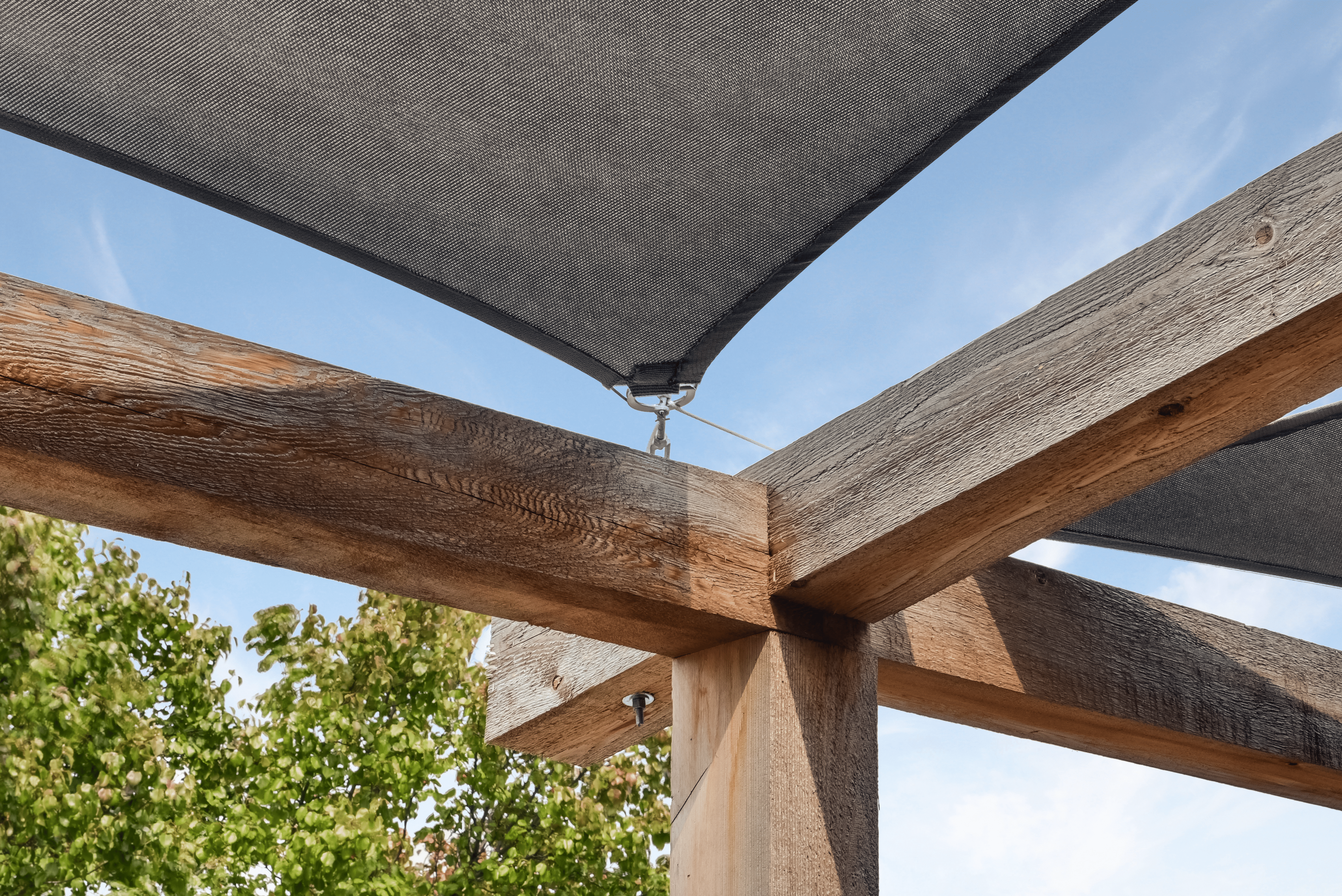

[Photo: Courtesy of Sunbrella]

High Design

Each of the three 9-by-12-foot shade sails is made of Sunbrella Contour with a cable sewn into a perimeter hem and attached with stainless steel turnbuckles and eyebolts through existing wood posts. “They fit perfectly within the rectangle areas, and they provide an artistic flair to the space, which contrasts with the industrial building that was repurposed into a restaurant,” Kellogg says.

And they took just five hours to install. “The customer was so pleased with the appearance and function of the first three Sunbrella shade sails we provided that he ordered a fourth shade sail for the western end of the patio.”

The quality, warranty, brand, and look of the fabric were reason enough to choose Sunbrella, Kellogg says, but the color was also exactly what the client wanted. “Contour is a much richer looking shade cloth fabric than any of the other shade sail fabric we presented to our client.”

If the owner hadn’t chosen Sunbrella, he would have been faced with a choice between other materials, which Kellogg says simply aren’t as nice. “Most of them are plastic-looking,” he says. “Sunbrella Contour is very soft to the eye and offers a much higher perception of quality and value.”

Of course, Sunbrella’s offerings improve not just restaurants and bars, but office buildings and even private residences, too. “In modern design, we want to have office environments that are conducive to innovative thinking, conducive to a community of colleagues working together to advance the mission of their firm,” Hankins says. He believes having comfortable, inviting places for people to work and think inspires greatness. Hankins says Sunbrella strives to work with leaders in architectural design and those who are pushing the design envelope for a myriad of spaces. Incorporating soft surface products from Sunbrella has the added benefits of design flexibility and better sound absorption, too.

Glen Raven, the maker of Sunbrella, has more than a century of history under its belt and continues to lead the industry when it comes to its long lifespan. “We were the first shade fabric to extend a warranty,” Hankins says, adding that that warranty—now 10 years—is worldwide, including in some of the harshest conditions on the planet.

Sunbrella promises its shade fabrics will stay bright and strong for many years to come. “The basis of its DNA is performance. It’s a highly tuned performance product,” Hankins says.

[Photo: Courtesy of Sunbrella]

R&D

Sunbrella fabrics are manufactured in facilities around the globe, with its main manufacturing location—a 1 million-square-foot facility in South Carolina—having an impressive R&D center and testing lab. Sunbrella’s expert designers are all over the U.S. and Europe, too.

Sunbrella puts tremendous investment into its people, making sure they have the best team to deliver high design and high-performance products that last. They’re constantly looking to unlock new and enhanced performance criteria and find the best shading materials. “We don’t just listen. We hunger and seek input from all kinds of diverse thought leaders and sources. And we utilize our human capital to search the globe for new ideas,” Hankins says.

As people become increasingly aware of the need for shade—both for comfort and health reasons—manufacturers and businesses alike look at how they can best deliver. That’s where Sunbrella steps in to move the conversation even further, asking: What else can be done? What else should they consider? And how can they help? “Shade markets and structures aren’t going to just grow on their own by coming out with a few new colors every couple of years or some different styling,” Hankins says. “We’ve got to much more actively engage and challenge the professional design and architectural community.”

Sometimes considering a shade structure isn’t top of mind for some design professionals, but Hankins says it should be. “It can enhance the facade. It can enhance the overall campus and site layout. It’s flexible. It can change and evolve. It can be styled over the lifespan of the building.”

RECLAIMED MATERIALS

Sunbrella doesn’t just say its product is recyclable. It follows through. “We bring the material back and it is repurposed and reconstituted,” Hankins says. Reclaimed materials then go into high-value products, setting Sunbrella apart from its peers.

This is nothing new for the company, though. They’ve been repurposing fabric scraps into felt materials for things like underlayment and liner material for years. But in the last decade, they’ve taken that idea much further with collections like Sunbrella Renaissance, now one of its best-selling collections. Sunbrella Renaissance fabrics combine up to 50% post-industrial recycled Sunbrella fiber with virgin Sunbrella fiber for vintage charm, rich color, ultra softness, and top-notch performance. “We have partners who help us process waste streams back into a usable fiber,” Hankins says. “We render this material back into fiber form so it can be spun into yarn. From yarn, we create beautiful, high-performing fabric.”

All Sunbrella fabrics are zero landfill, GREENGUARD Gold Certified, and OEKO-TEX certified, among other environmental certifications.

Read more about Sunbrella.