[Photo: Courtesy of Aquafil]

How one supplier for carpet manufacturers is making radical changes toward a circular economy

Fifty-three years ago, few could have guessed that a company founded to create yarn for textile flooring in Arco, Italy, would become an international leader in creating sustainable, circular economies. Even fewer may have guessed that organization would become a model for creative partnerships.

“At the beginning it was quite a traditional business,” says CEO Giulio Bonazzi, second generation leader of the family-owned Aquafil, a top supplier for commercial and residential carpet manufacturers. As the business expanded, Bonazzi moved quickly up its leadership chain. He started first as an assistant production manager at the Arco plant before taking over division management and then moving on to spearhead the company’s move into its Slovenia operations.

Bonazzi soon reached the helm of the family business, where, in 2011, he had the idea to combine waste reduction with the production of nylon, Aquafil’s primary product. At that point, the company morphed into something decidedly nontraditional.

FROM OUR JULY+AUGUST 2018 ISSUE

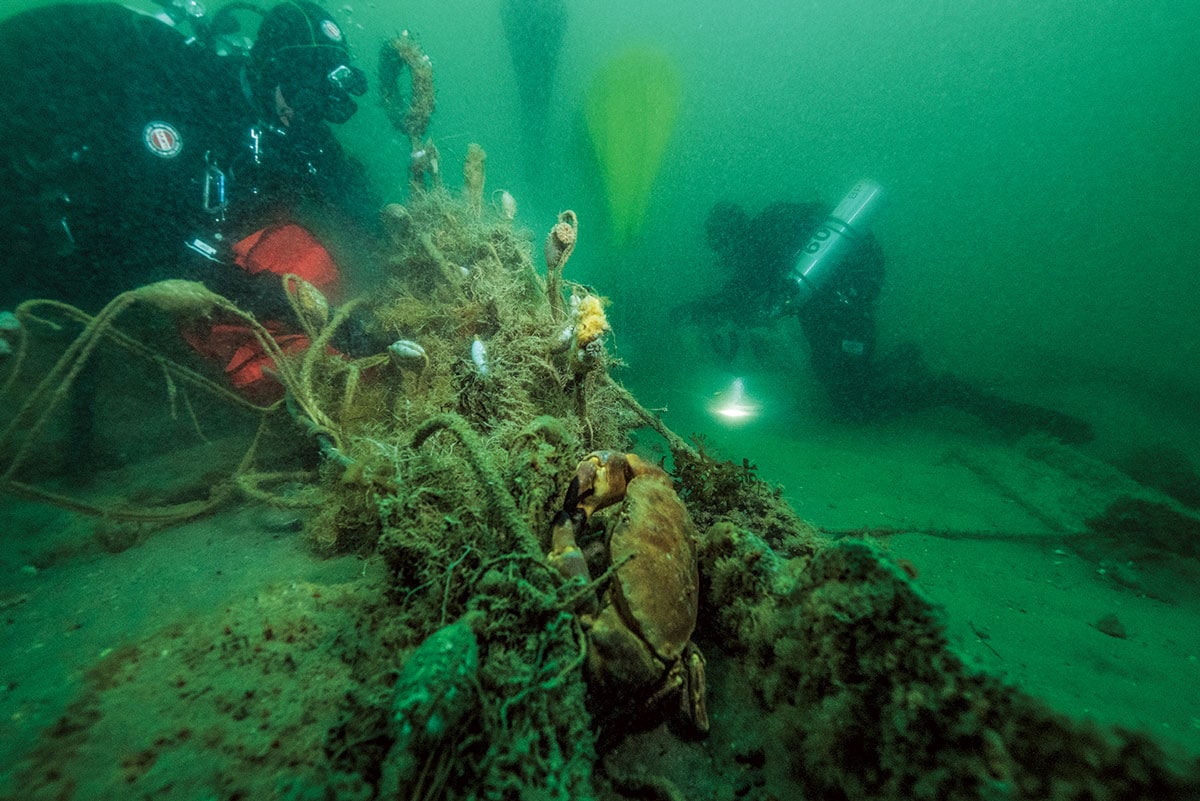

[Photo: Courtesy of Aquafil]

New Model(s)

Nylon 6—or polycaprolactam—is one of the most commonly used nylon products across industries, from aircraft to electronics to clothing and construction.

Aquafil’s standout product, ECONYL®, is a nylon 6 fiber derived fully from regenerated waste materials. It’s been loudly featured in products like Speedo swimsuits and designer Stella McCartney’s Falabella GO bags. More quietly, ECONYL fabrics meet almost every need across the residential and commercial building sectors: Interface, Milliken & Company, Desso, and Modulyss are all using ECONYL fibers.

[Photo: Courtesy of Aquafil]

Approximately one-third of all the nylon 6 yarn made by Aquafil is made with ECONYL. [Photo: Courtesy of Aquafil]

Today, approximately one-third of all the nylon 6 yarn made by Aquafil is made with ECONYL. This is no side project.

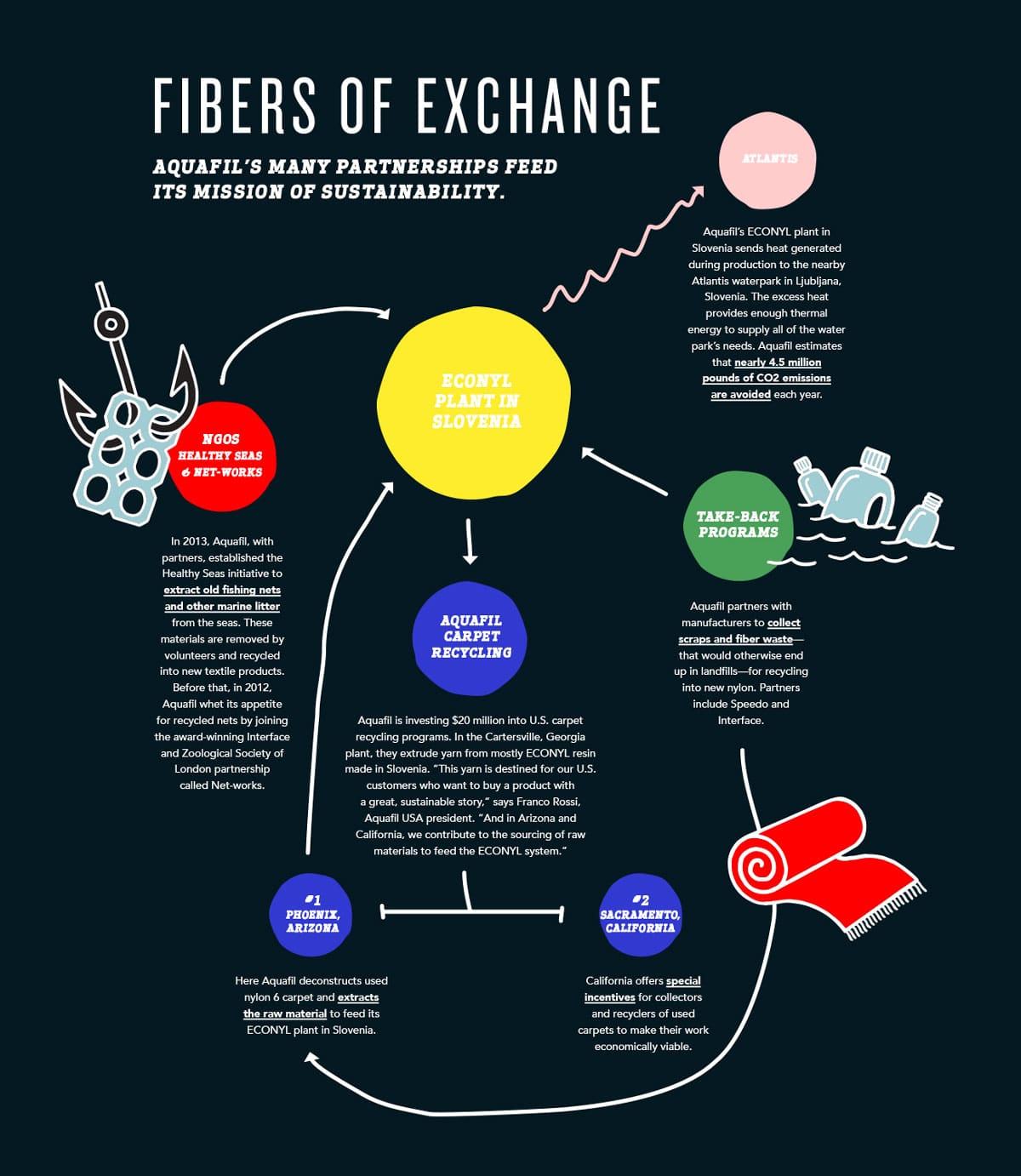

But despite his vision for a closed-loop nylon economy, or perhaps because of it, Bonazzi knew Aquafil couldn’t collect and recycle nylon on its own. The story of ECONYL’s development is also the story of Aquafil’s breakout into the world of sustainability partnerships. “We needed to find partners outside of our supply chain to develop a reverse logistic that could assure a constant supply of waste material to a plant running 24-7-365,” Bonazzi says.

As it turns out, Bonazzi’s team found many.

What’s Next

Aquafil’s success with its ECONYL partnerships are exciting, but they aren’t the end of Bonazzi’s vision.

He’s mostly secretive about what’s coming down the line, but he is excited about the upcoming partnership with Genomatica, a San Diego–based biotechnology company and manufacturing innovator.

The two companies have announced a multi-year agreement to create sustainable caprolactam, an organic compound and an ingredient integral to producing 100% sustainable nylon. The collaboration will work to develop a commercially advantageous caprolactam using plant-based renewable ingredients, instead of the fossil fuel–based materials more traditionally used by the nylon industry.

“This is a project we will be involved in for the next several years and we are very excited about,” Bonazzi says, underscoring his real goal: radically transforming the carpet industry through partnerships and circular economy.

[Photo: Courtesy of Aquafil]

Q&A with Giulio Bonazzi

Q: Over your years of working on diverse projects with diverse groups, when have you found collective action and partnerships to work best or to be most beneficial?

A: The most beneficial collaborations are the ones that are connected to the business models of partners. Everyone does what they know best and what they need to do from a business standpoint. All together, they are also helping the environment and improving production processes.

Q: What makes a good sustainability partnership? What makes a bad one?

A: It goes back to a connection to a partner’s business model: So the partnership is not something special that you do once and then forget about. It’s something that brings a profound change in the way you manufacture your product and in the way you do business.

Business culture is also important. It’s fundamental that people in the partnership have a similar DNA and a common, clear goal that is beneficial for everyone and for the community. This leads to longer commitment, which is what is needed for a real system change.

Q: What about these partnerships keeps you inspired?

A: Entities in different industries and with different backgrounds coming together for a common goal!