The iconic beverage brand is water neutral. How is your business navigating sustainability?

The year 2004 was not a good one for soft drink giant and American icon Coca-Cola. The company was charged with illegally depleting groundwater in Kerala, India, where persistent drought continues to stress local villages, wells are running dry, and farmers complain of poor harvest yields.

A high court ultimately sided with Coca-Cola’s claim that the water was sourced legally, but the community’s uproar and subsequent distrust, right in the backyard of one of Coke’s bottling plants, was a wake-up call. “We essentially lost our social license to operate and access water in that community,” says Jon Radtke, water sustainability program director at Coca-Cola North America. “What we failed to do then was look outside the four walls of our plant and into the community at the issues they were going through. We’re part of that community, and the correct response would have been, ‘How can we help this situation?’”

FROM OUR JAN+FEB 2019 ISSUE

The preferred publication of leading green professionals.

Striving to Do Better

The legal battles and heated accusations that followed Coca-Cola’s operations in India from 2004 onward drove the company to take a hard look at all of its operations across the globe. Coca-Cola sells in more than 200 countries worldwide, where its namesake secret formula is trucked in as a concentrate and mixed with water, sweetened, bottled, and sold by local franchise bottling companies.

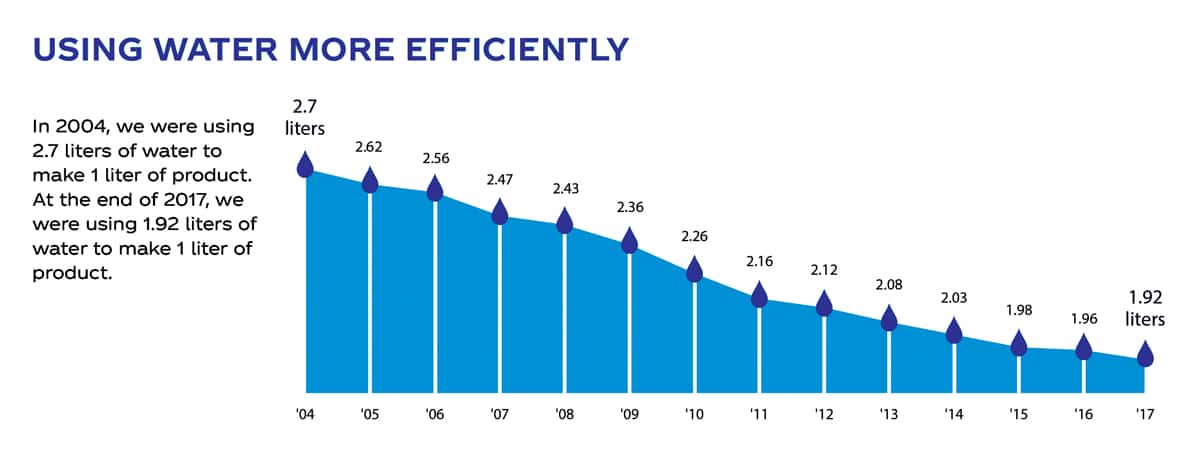

In 2004, the company used 2.7 liters of water to make every 1 liter of Coke, meaning water waste was nearly double Coke’s product output. Coca-Cola won’t disclose exactly how much product it sells each year, but its website claims more than 1.9 billion servings of its drinks are consumed each day. Suffice it to say, water waste was significantly higher.

Following the controversy in India, Coca-Cola conducted risk assessments and performed source water vulnerability assessments at all of its plants. “Those included everything from looking up to the headwaters of a watershed to look for stress or quality problems, but we also looked at community issues,” Radtke says. “Is there sufficient infrastructure? We know we use water, but we don’t want to use up water to detriment of our neighbors.”

Soon after Coca-Cola unveiled its vision of becoming water neutral—replenishing 100% of its water use back to the earth. The goal was to become water neutral by 2020, but the company reached that mark five years early. The year 2018 marks the third year Coke has balanced 100% of the water it uses.

Reaching Replenishment

In North America alone, Coke has around 70 active water replenishing projects. Just one of those is a massive rainwater harvesting project in more than 100 U.S. communities. “We donate secret formula bins to municipalities and provide conversion kits and workshops to convert them into rain barrels,” Radtke says. The company has donated more than 90,000 rain barrels in 10 years of the program.

In the Sierra Nevada mountains, severe drought was turning parts of a nationally treasured mountain range into a barren wasteland. Radtke and his team worked with the U.S. Forest Service to plug streams with soil plugs to reestablish the natural environment around the Mokelumne River, which provides water for the East Bay Municipal Utility District around San Francisco.

In Texas, the team worked on invasive species removal along both the American and Mexican sides of the Rio Grande River in Big Bend National Park, where the reed known as giant kane was choking out local species. “Giant kane is super thirsty, and we funded projects to remove it, either by cutting it down or by burning it,” Radtke says. With continued maintenance, he estimates the project has saved billions of liters of water.

Leading by Example

Coca-Cola has made a lot of changes to reduce its water use from 2.7 liters of water to make one liter of Coke to 1.92 liters to make one liter. “There are so many things we do at Coca-Cola, like using air rinsers to clean equipment. We replaced water-based lubricants with dry, silicon-based lubricants. We have a dry-floor mentality in our plant, and we’re working with employees in operations to empower them to come up with ways to save water. It’s changing culture inside of the plant,” Radtke says.

He says it’s one thing to set goals at a company, but implementing them is the hard part. “You have to convince leadership to spend resources on projects and to think long-term,” he says. “When we invest money in watershed restoration, we don’t get a direct, fast return on investment. Our payback is 10 years down the road. For Coca-Cola, we don’t have a company without water.”