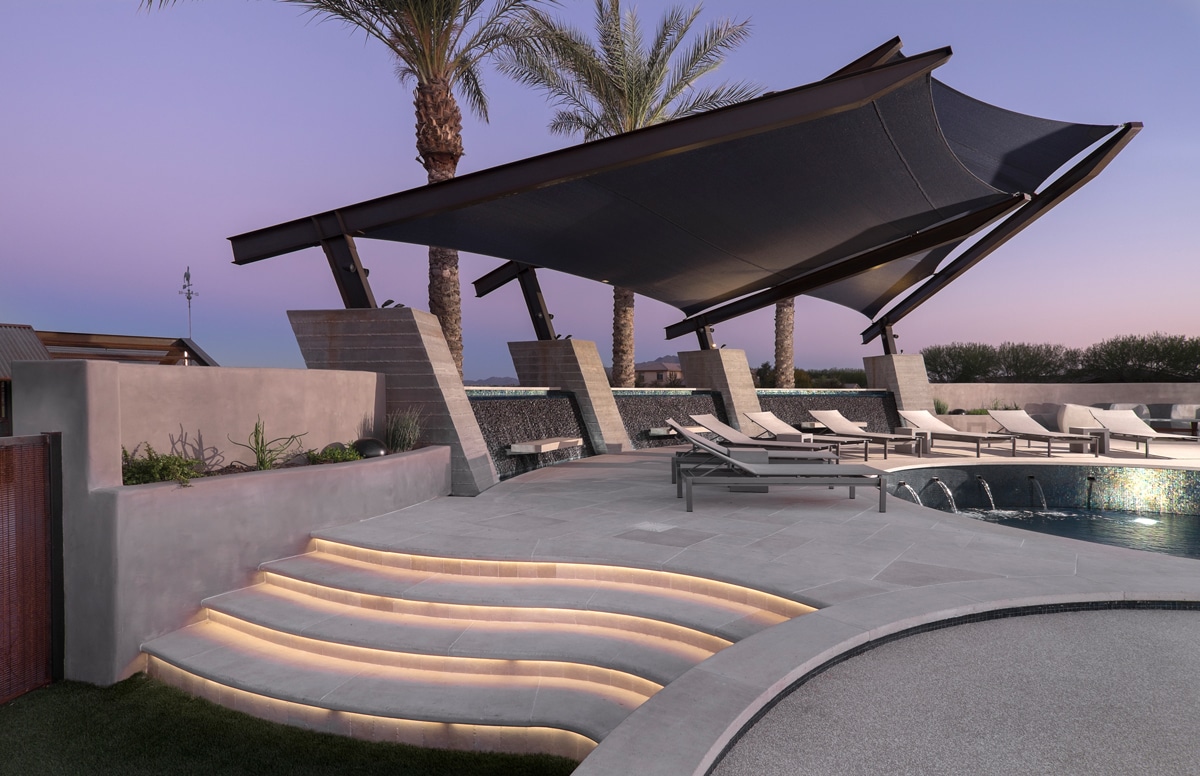

GALE Pacific continues to innovate with new shade fabrics, as the pioneer behind the world’s first shadecloth knitting technology. [Photo: Courtesy of Shade Industries]

Advanced Technical Textiles from GALE Pacific protect people and places from the elements.

You wouldn’t head to the beach without your hat and sunscreen. So it is too for architects and business owners, who are increasingly realizing that shade products are an essential consideration for outdoor areas. GALE Pacific has long understood the importance of sun protection. GALE Pacific pioneered the world’s first shadecloth knitting technology decades ago, which has been successfully used in temporary and permanent outdoor applications.

The company began as a small Australian scarf-knitting mill but today is the world leader in advanced polymer fabrics. It all started back in the 1970s, at the invention of shade fabrics, explains Andrew Nasarczyk, research and development manager for GALE Pacific. These heavy-duty fabrics were initially designed for agricultural and horticultural applications to protect crops from adverse weather conditions and optimizing growing conditions. The company knew there was more potential, he says, so “we took that principle and applied it to people.”

What followed was the invention of higher UV block shade fabrics, a high-performance solution that provides superior protection from UV rays while allowing cooling breezes to pass through. Unlike competitors who create shade products out of canvas, acrylic, and solid PVC sheet, GALE Pacific uses unique knitting techniques that allow air to circulate and make the fabric breathable. This prevents the shade structure from trapping heat inside. These fabrics are designed for shade sails and tension structures you can find in playgrounds, schools, and restaurants as well as protecting parking lots, offering privacy screens, and creating awnings.

Today, GALE Pacific is the world leader in advanced knitting and coating technologies, and the company is always looking for opportunities to further develop and innovate its product portfolio. “We’re constantly striving to increase levels of UV stability and UV protection to ensure a longer-life product that provides better protection to people,” Nasarczyk says.

Here are some of the top reasons that set GALE Pacific apart from the rest.

FROM OUR JAN+FEB 2019 ISSUE

The preferred publication of leading green professionals.

You’ll find these durable fabrics on playgrounds, at restaurants, protecting parking lots, and more. [Photo: Courtesy of Shade Industries]

Built to Last

For business owners like Patrick Howe, CEO of Wholesale Shade, a California-based designer and installer of custom shade sails, GALE Pacific’s reputation for high-quality work is essential. “People choose GALE Pacific because they have a proven track record,” Howe says.

Back in 2008, when Howe founded his company, GALE Pacific was one of the only suppliers of high-performance shade fabrics. A number of competitors have since entered the space, he notes, but none has them beat in terms of durability and quality. “There’s no drama,” Howe adds—he simply gets products that outlast their warranties.

Safe for People

GALE Pacific is vertically integrated and thus controls the entire life cycle of its products. This gives the company complete control over each component, from the selection of raw materials to the manufacturing process, control of quality, customer service, and ongoing technical support. The company has demonstrated its commitment to responsibly manufactured products by obtaining a third-party certification known as the OEKO-TEX Standard 100, which restricts the presence of dangerous chemicals in the fabric manufacturing process. The company was the first to obtain this certification for shade cloth, proving its commitment to being a responsible manufacturer.

In addition, all the shade products are 100% free of phthalates and lead, offering end users peace of mind. And GALE Pacific’s Commercial Knitted Fabrics such as Commercial 95® and Commercial Heavy are also certified by Greenguard’s children and school certification. This puts strict limits on volatile organic compounds, or VOCs, as well as formaldehyde emissions. Additionally, while competitors may use surface dyes to color their textiles, GALE Pacific spins its yarns and knits its fabrics in-house, so it’s able to incorporate dyes into the extrusion process.

“We invented HDPE shade fabrics in the ’70s. We know our products outlast their warranties. We can back our products and continuously innovate moving forward,” says GALE Pacific’s Andrew Nasarczyk. [Photo: Courtesy of Shade Industries]

Sustainably Made

The company takes a multi-pronged commitment to sustainability, approaching its mission from all angles. In addition to the environmentally friendly manufacturing practices, GALE Pacific adheres to a cradle-to-cradle approach. “Our products are inherently designed to last for a long period of time, and once they do reach end of life, they can be recycled,” Nasarczyk says.

The fabrics are recycled back into polyethylene pellets, which can then be used in myriad ways, from new shade fabrics to alternative applications. “Sustainability is a key value of our business, and we certainly want to be a market leader in this space,” he says.

What is UV Stability?

This is an essential concept in shade control. According to Andrew Nasarczyk, research and development manager for GALE Pacific, it’s essentially a measure of how long a product will maintain its integrity before being damaged by the sun.