MirrorLite is known for its innovative, reflective glassless mirrors.

[Photo: Courtesy of MirrorLite]

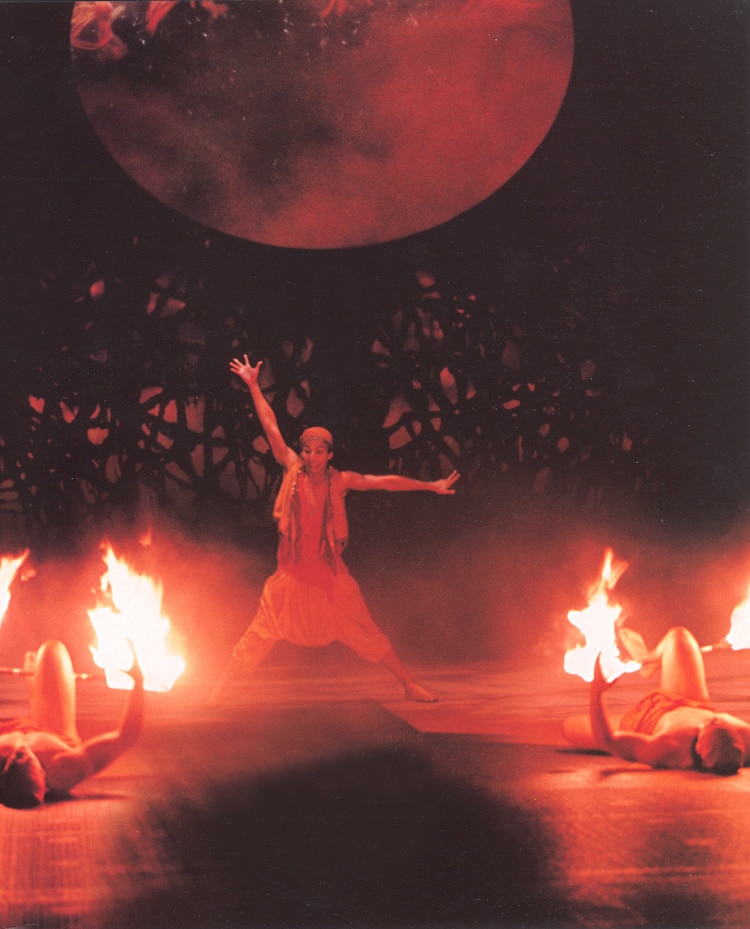

From high-end hotel ceilings to stage design for Adele’s “Skyfall,” MirrorLite is known for its innovative, reflective glassless mirrors. Their flexible film technology provides the distortion-free properties of traditional glass—high luminosity and reflectivity—without the risk of shattering.

British Aerospace developed glassless mirror technology after World War II. It wasn’t until the late 1980s when the commercial use of glassless mirrors came into play. MirrorLite acquired the manufacturing license from British Aerospace to begin developing its own mylar mirror film. “Our motto is ‘reflection of quality,’ not only in the product itself, but also in how we work with architects and clients,” says Gary Reith, MirrorLite’s president and founder.

FROM OUR JANUARY+FEBRUARY 2018 ISSUE

The preferred publication of leading green professionals.

[Photo: Courtesy of MirrorLite]

Ambitious Projects

Since it began in 2007, MirrorLite has worked on projects across the globe—from the Mandarin Oriental Hotel’s ceiling in Qatar to Thomson Consumer Electronics’ corporate headquarters in France. “For being a small business of 20 employees, we certainly get involved with projects around the world,” Reith says.

Recently, MirrorLite completed a $10 million lobby in Lafayette Tower—Washington D.C.’s first LEED Platinum certified office building. “Our custom-shaped mirrors gave the reflection they were looking for, but also allowed for all the necessary functions in a building lobby—like efficient lighting and fire detection technology,” Reith says.

The project wasn’t without its challenges, though. The team faced difficulties such as creating the intricate shape of the octagonal mirror, constructing more than 50 custom mirror shapes on two levels, and working with a ceiling height of more than 25 feet. The project’s tight deadline meant Reith and his team had to be ambitious and quick to adapt. The lobby was completed in less than two months from start to finish, a major feat in speed and service.

Glassless mirrors are 85% lighter than conventional mirrors of the same size, making them easier to transport and install.

—

MirrorLite also partnered with Leek Building Products, Inc. on the MGM Grand Casino in Las Vegas. This large-scale project incorporated sound-absorbent panels below of the mirror mylar film. “In a noisy casino, sound absorption is important,” Reith says. “The ceiling panels not only serve as a decorative mirror finish, but also absorb excess sound.”

“We wanted to keep the noise levels manageable while having a reflective look with large paneled sections,” says Bill Leek, president of Leek Building Products. Leek used his strong acoustical background to help the team develop its noise control strategy, and he ruled out traditional mirrors. “Mirrors are highly reflective but have no acoustical value,” he says. A normal sheet of glass would enhance the echo, but MirrorLite panels’ special foam board absorbs sound. “MirrorLite’s glassless mirrors flex when the sound wave hits them, transmitting the sound into the cavity behind the mylar film.”

The project not only stayed within budget; it was completed on time. “It was a labor-friendly project,” Leek says. “It was a large project, too—not just a little piece of two-by-four glass. Luckily, MirrorLite’s glassless mirrors are lightweight and easy in terms of installation.”

[Photo: Courtesy of MirrorLite]

Reflecting a Greener Outlook

MirrorLite strives to be eco-friendly and never lets materials go to waste. “If the mirror surface is ever damaged, you can use the same frame and just put on new mylar film,” Reith says.

MirrorLite recycles and reuses every material it can, too. For temporary mirror projects, the mylar film is stripped off and recycled. The mirror frame components are disassembled and either recycled or resized and reused in other projects. It’s also one of the first companies to use water-based adhesives for assembly. And the MirrorLite panel inherently increases thermal insulation, which decreases overall energy usage and costs.

Benefits of Glassless Mirrors

“The lightweight properties of MirrorLite allow architects to design larger mirror panels than conventional glass,” Reith says. Glassless mirrors are 85% lighter than conventional glass mirrors of the same size, making them easier to transport and install. For some installations, MirrorLite uses Dual Lock Reclosable Fasteners, which Reith likens to “velcro on steroids.” The installation team simply clicks the mirror panel into place and can easily remove it at any time.

MirrorLite’s glassless mirrors are also safer and more durable because they’re shatterproof. Glassless mirrors have a rigid foam core that gives them more stability. To form the mirror’s reflective surface, the manufacturing team stretches mylar film across the frame’s raised edges. The cavity between the back of the film and the core gives the mirror enhanced flexibility and helps protect it from damage.

[Photo: Courtesy of MirrorLite]

Looking Ahead

MirrorLite’s future is brighter and greener, too, as Reith aims to go solar. “The glassless mirror panel lends itself well to the solar energy industry,” he says.

MirrorLite is also experimenting with tinting mirrors different colors, as well as developing a permanent on-site installation system to accommodate venues with restricted door openings. The company has completed several test installations for short-term projects. “When it comes down to it, we want to provide a solution and make glassless mirrors that will work for our clients’ needs,” Reith says.

Learn about MirrorLite and read more gb&d glass stories.