[Illustration: Carolyn Sewell]

Google is in the business of glass, and we don’t mean Glass of the high-tech optical variety.

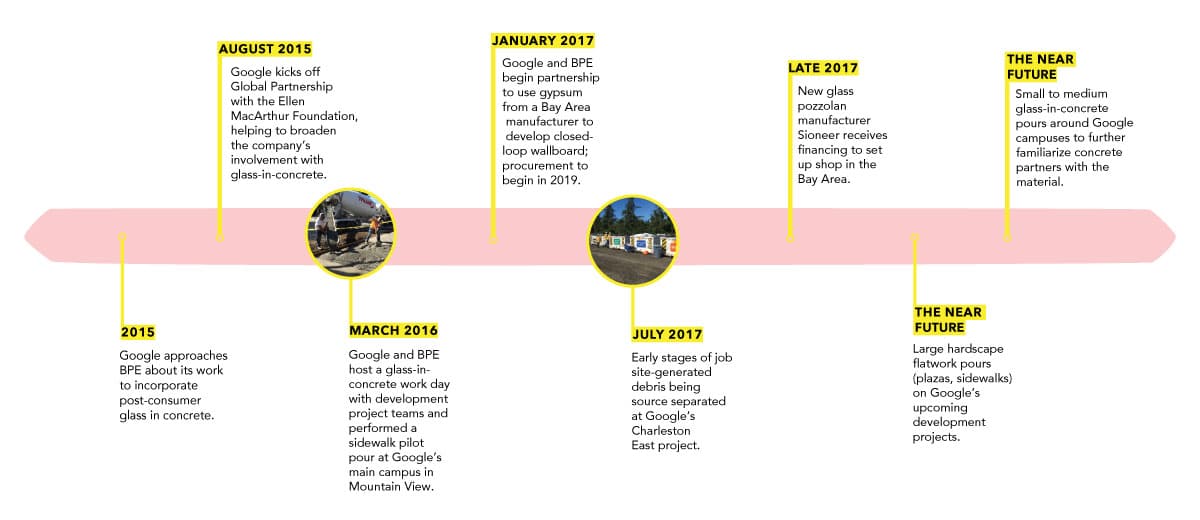

In its partnership with Building Product Ecosystems, the tech giant is exploring the world of recycled glass, poured concrete, gypsum, wallboard, and the sustainability of its built environments. It’s an inspiring collaboration with two parts:

The first is piloting the use of post-consumer glass as a cement replacement in concrete. If successful, the project would divert waste from landfills worldwide and help break the building industry’s dependency on byproducts from fossil fuels.

The second wants to close the loop on the manufacturing of gypsum wallboard. By recovering some or all of the thousands of tons of wallboard scraps that end up in U.S. landfills each year, Google and BPE hope to minimize waste and the environmental impacts of gypsum mining. By recycling wallboard from construction and renovation sites, they hope to maximize product reuse within regional supply chains.

Post-consumer glass recycling, concrete, and gypsum wallboard don’t sound nearly as sexy as the boundary-pushing technology Google is most known for, but the work is absolutely foundational. “Sustainability is Google’s quiet moon shot. Tough problems, long bets, and innovation are part of the company’s culture,” says Robin Bass, lead of the Google team spearheading this collaboration. “If we can prove sustainable business techniques just make sense, we hope the industry—from manufacturers and suppliers to real estate developers—will decide to invest in these techniques as well.”

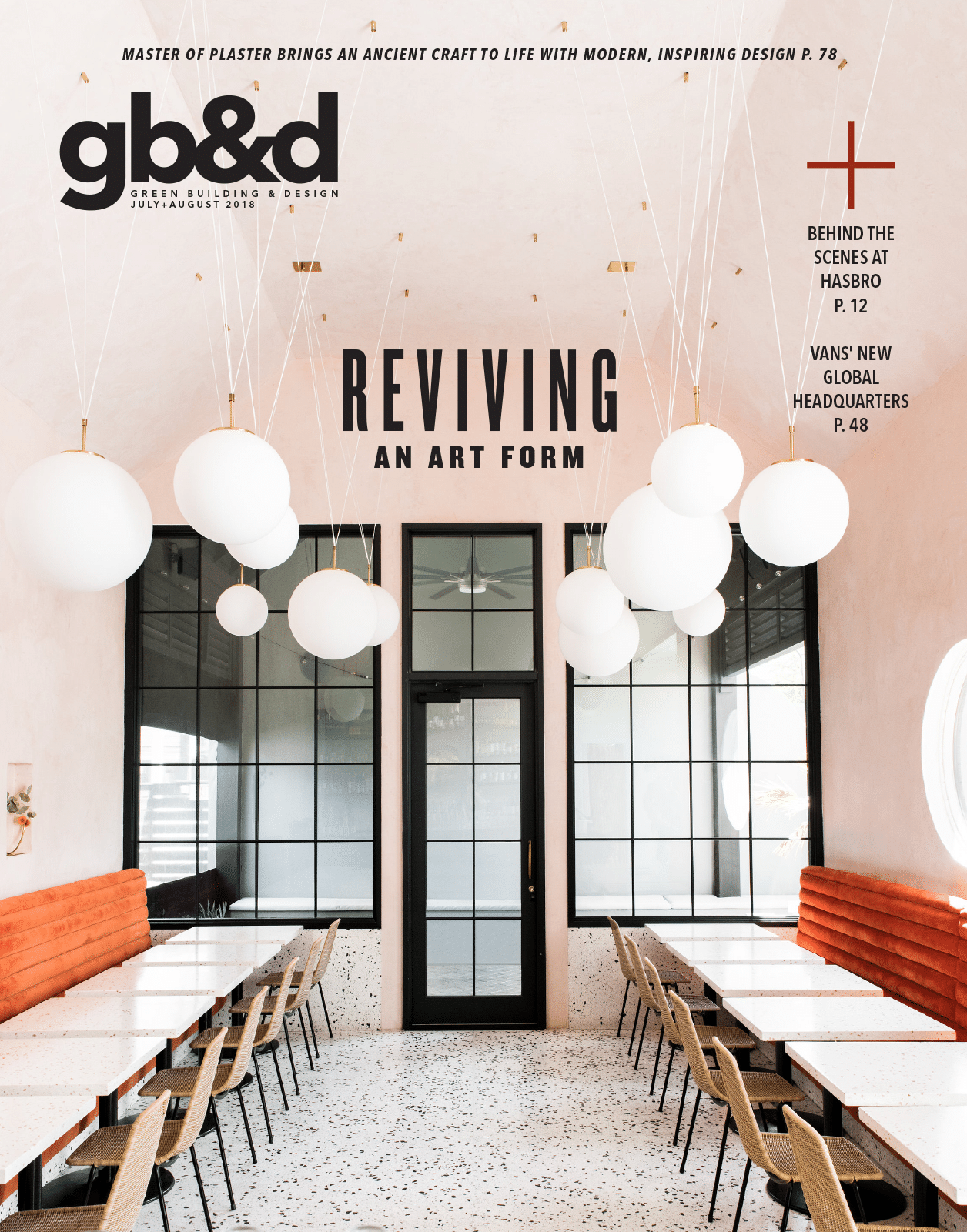

FROM OUR JULY+AUGUST 2018 ISSUE

[Illustration: Carolyn Sewell]

Meet the Players

Building Product Ecosystems + Amanda Kaminsky

In 2014, Amanda Kaminsky founded Building Product Ecosystems with the Durst Organization, one of New York City’s oldest and largest real estate firms. BPE was founded as a public-private partnership with City University of New York and The New School, among others. With Durst, BPE began its initial exploration of flame retardants and codes, evolving wallboard systems and using glass in concrete. Eventually the organization outgrew its one-building-at-a-time approach to change-making. In 2016, BPE expanded to become an independent LLC focused on collaborative consulting. This was around the same time Google came onboard.

Google [e]Team + Robin Bass + Andreas Gyr + Karen Burbano

[e]Team is a division of Google’s Real Estate and Workplace Services section and focuses on health and sustainability inside the company and out. “Buildings are our products,” Bass says. “We focus on the people in our buildings the way Google engineers focus on the user.”

At the end of 2015, Google approached BPE about its work to incorporate post-consumer glass in concrete. Google’s first ground-up development projects in its Mountain View campus were just getting going, and [e]Team wanted to find an alternative to the coal plant byproducts typically found in concrete mixes. “Our glass-in-concrete pilot whet our appetite for circular economy solutions in the built environment,” Bass says.

From there, Google began making moves with BPE to close the loop on wallboard. Procurement will begin early next year. “Shaking up the status quo can be fun and impactful,” says Karen Burbano, Google’s wallboard team lead. “We need to reimagine how we produce every building product because resources are finite. We do not have room for more landfills. We need to support manufacturers who are willing to challenge the status quo and reexamine their manufacturing practices.”

The Challenge

Google and BPE join major players looking at sustainability through collaboration by asking: Can finely ground post-consumer glass be used as an additional substitute material in concrete to reduce carbon footprints, minimize exposure to potentially toxic materials, and find a much-needed use for post-consumer glass?

[Illustration: Carolyn Sewell]

The Facts

- More than 60% of generated glass in the U.S. ends up in landfills each year, the EPA says.

- Cement is a fine powder produced by heating and grinding limestone and clay minerals and mixing them with gypsum. About 84 million Tons of Portland cement were produced in the U.S. in 2017, according to the U.S. Geological Survey, resulting in approximately 84 million tons of carbon dioxide emissions.

- Post-consumer glass can be used to produce glass pozzolan, which can replace cement in concrete.