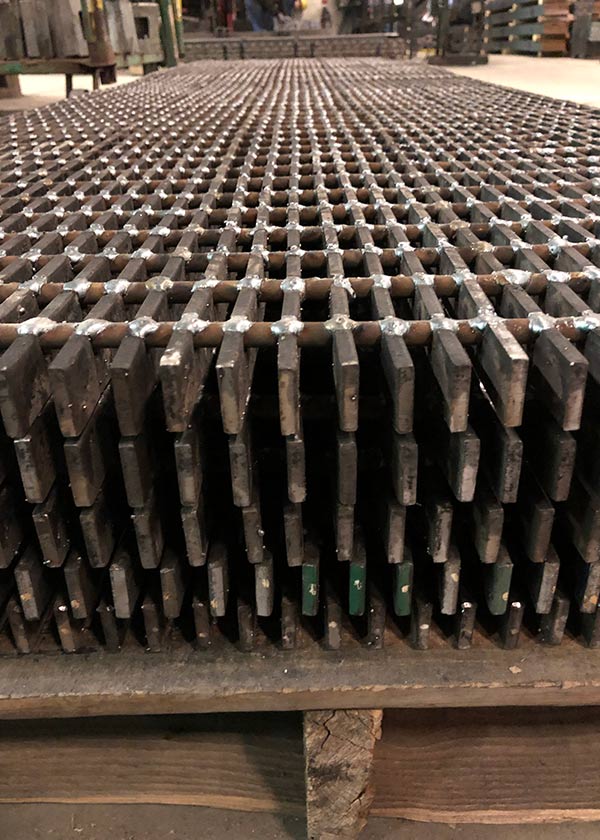

From tailored crossbars to added skid resistance and beyond, grating offers a bounty of customization options.

[Photo: Courtesy of Laurel Custom Grating]

Unlike many steel manufacturers, Laurel Custom Grating (LCG) always takes on custom products for its customers to best serve their individual project needs. LCG has been manufacturing specialized items like special alloy high impact-resistant grates and other complex application-specific grates since its founding in 1983. The company is also able to provide customized gratings to contractors who need products heavy enough to withstand vehicle loads while still complying with the federal Americans with Disabilities Act. Bill Adams, sales team lead at LCG, recently outlined the vast custom options for steel grating.

Before diving into custom options, a little background on the basics of grating design: A bearing bar is the primary load-carrying element; it’s a flat bar of virtually any height or thickness. Bearing bars have consistent spacing between them, based on a project’s needs. Crossbars are welded to the bearing bars.

[Photo: Courtesy of Laurel Custom Grating]

Design options are abundant for steel grating. LCG can meet practically any open-air requirements by adjusting the bearing bar size and spacing. Heavy duty steel grating usually comes in standard widths, but if a customer needs a little bit of wiggle room, anywhere from a quarter-inch to several inches, our welders can manipulate the bearing bars as needed. During the fabrication process, welders can extend the bars out, or make certain cutouts to allow the grating to fit in a specific trench or platform. They can also adjust the grating to fit around fixtures like steam pipes or drain pipes.

Crossbars can be customized to increase load-bearing capabilities. In a roadway application, if traffic goes in the direction of the crossbars, a rectangular crossbar offers better load distribution than a standard smooth round crossbar. Bottom crossbars can also be added for more load-bearing support.

[Photo: Courtesy of Laurel Custom Grating]

If you need additional traction or skid resistance, the product can be customized to have a serrated grating surface. Customization options are limitless—from hopper covers and heavy material-handling screens to radio frequency screens for national security installations. LCG can also customize grates for cast in-place drainage boxes and troughs, ideal for the precast industry.