As apartments, hotels, condominiums, casinos, and the like continue to push skyward, with the rise in building height comes a corresponding rise in the expectations of owners and guests for amenities such as elevated pools and spas.

When designing or specifying an above-ground pool or spa, especially those built over occupied spaces, there are a number of critical key elements that need to be carefully considered—the biggest of them all is material. And no above-ground pool or spa comes with as many benefits as stainless steel pools. Here are seven reasons why.

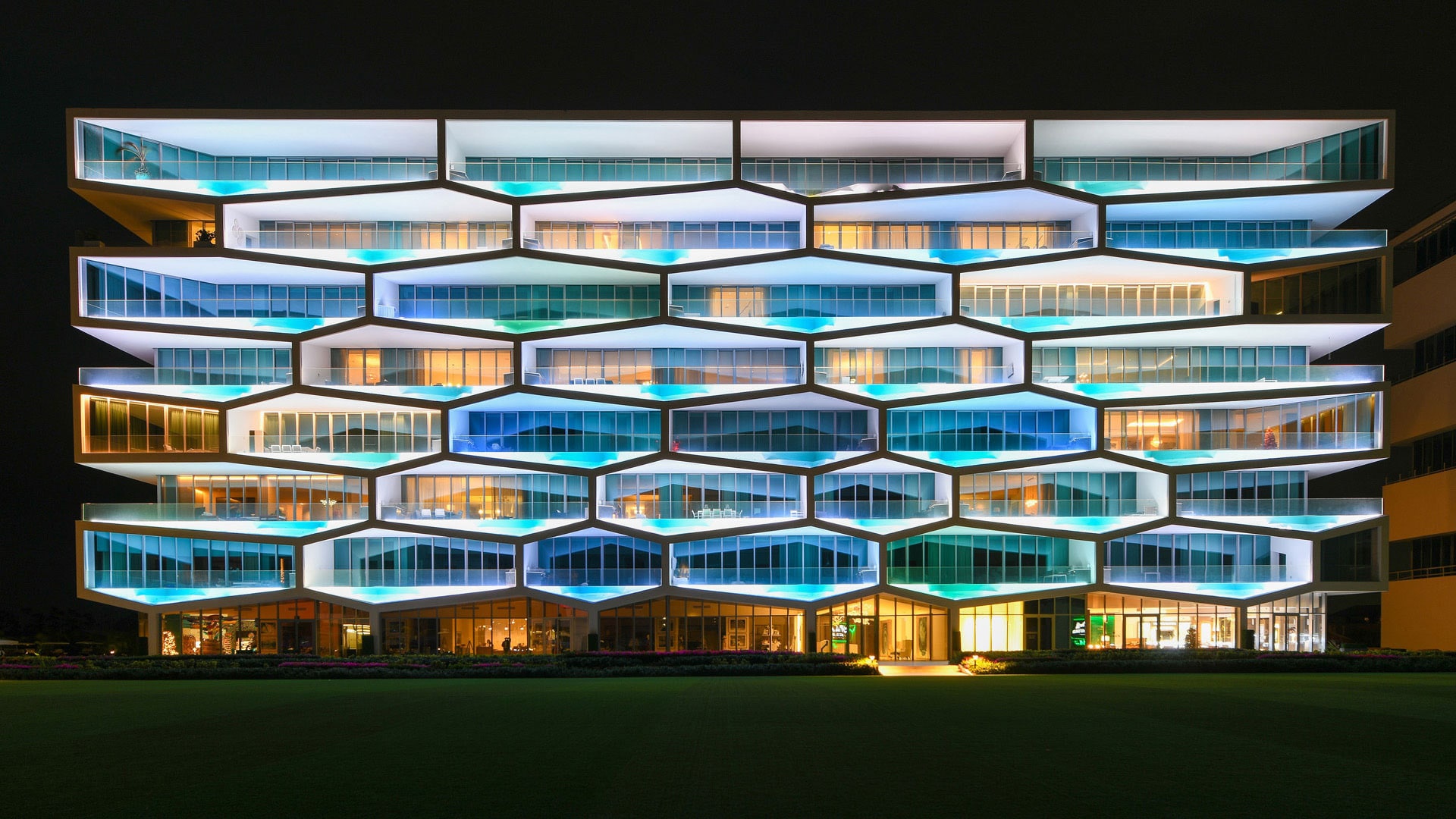

The Honeycomb Albany Bahamas is a residential building with a private pool on each balcony overlooking the marina. Photo courtesy of Bradford Pools

1. Leak-Free

Whether it’s a simple spa on a third floor residential balcony or a marquis pool on the roof of a five-star hotel, leaks simply cannot happen in above-ground aquatic applications. The potential liability and catastrophic damage associated with leaking pools and spas over living, retail, gaming, or other occupied spaces can spell disaster.

Stainless steel pools and spas like those from Bradford Products that are fully welded—that is, all floors and walls are constructed of welded stainless steel—can ensure a 100% leak-proof vessel.

All Bradford pools and spas are also hydrostatically water-tested prior to commissioning to confirm total water tightness. To top that off, Bradford backs every stainless steel pool and spa with an industry leading 25-year vessel corrosion warranty, giving you and your client total peace of mind.

The stainless steel rooftop pool at 363 Bond in Brooklyn, New York, has a perfect view of the NYC skyline. Photo courtesy of Bradford Pools

2. Lighter Weight

The substantial weight of a traditional concrete vessel is just one consideration when designing an elevated pool or spa. The required additional support for a concrete vessel can also have significant impacts on structural costs and headspace loss in a new building and can limit the allowable size of a pool or spa in a reconstruction project.

Stainless steel pools and spas, including the required support structure, weigh just a quarter to a third of a comparable concrete vessel. This weight savings can dramatically reduce structural costs and construction time, frees up valuable headspace around or below the pool, and allows for more expansive designs in tight quarters and existing building renovations.

This Miami stainless steel pool is the backdrop for the perfect day in the sun. Photo courtesy of Bradford Pools

3. Easy Installation

Time is critical in any construction project, especially in complicated multi-story structures. All Bradford stainless steel pools and spas are fully pre-fabricated in our factory, then delivered in one piece or multiple large sections. Final installation is typically completed in a matter of weeks instead of months.

Not only does this significantly reduce installation costs and resources, but it also frees up other trades to work in close proximity to the pool or spa with minimal interruption. In regions with limited building seasons due to weather and temperature, stainless steel pools and spas can be installed in almost any environmental condition, free of the traditional concerns related to concrete forming, pouring, and curing.

4. Lifetime Durability

The durability and performance of stainless steel is well documented across a wide array of demanding applications. Not only does it look beautiful, but stainless steel is also designed to perform for decades in challenging environmental and operational conditions.

One of The Cosmopolitan’s rooftop pools in Las Vegas includes custom water features. Photo courtesy of Bradford Pools

5. Customizable Designs

A pool or spa is only as good as its design, and with Bradford the possibilities are virtually limitless. Stainless steel pools with complex shapes, clear viewing widows, elegant spillovers, stunning finishes, and a host of other intricate details are what we create every day.

Don’t care for the look of bare stainless steel? No problem. Bradford pools and spas can be finished in an almost infinite range of tile choices to not just complement an intended design aesthetic but to become the centerpiece of any aquatic or recreational space.

Every vessel we build is meticulously engineered, precision-fabricated in our 200,000 square foot manufacturing facilities, and completely pre-assembled prior to shipment. This ensures not only an exact fit on the job site, but that your Bradford pool or spa is a fully accurate reflection of the intended design.

In Philadelphia, this stainless steel pool includes custom tile work. Photo courtesy of Bradford Pools

6. Increased Hygiene

Now more than ever clean, hygienic materials are a must for any surface a person may come in contact with. The naturally dense, nonporous surface of stainless steel is an ideal material for limiting areas where harmful bacteria and pathogens can potentially survive and thrive. Stainless steel is also easily able to withstand frequent, rigorous cleaning and disinfection protocols that are now becoming the norm.

The stainless steel rooftop pool at the Waldorf Astoria Beverley Hills. Photo courtesy of Bradford Pools

7. Sustainability

Bradford utilizes only top-quality, US-milled stainless steel in its vessels. These steels incorporate more than 60% post-consumer recycled content and are fully recyclable at the end of the vessel service life.

Just as important, Bradford believes that sustainability starts with durability, so every stainless steel pool and spa is designed to last a lifetime. Not only does this significantly extend the replacement cycle of the pool or spa, but it also eliminates the need for the costly and messy refinishing and resurfacing requirements of traditional aquatic vessels.