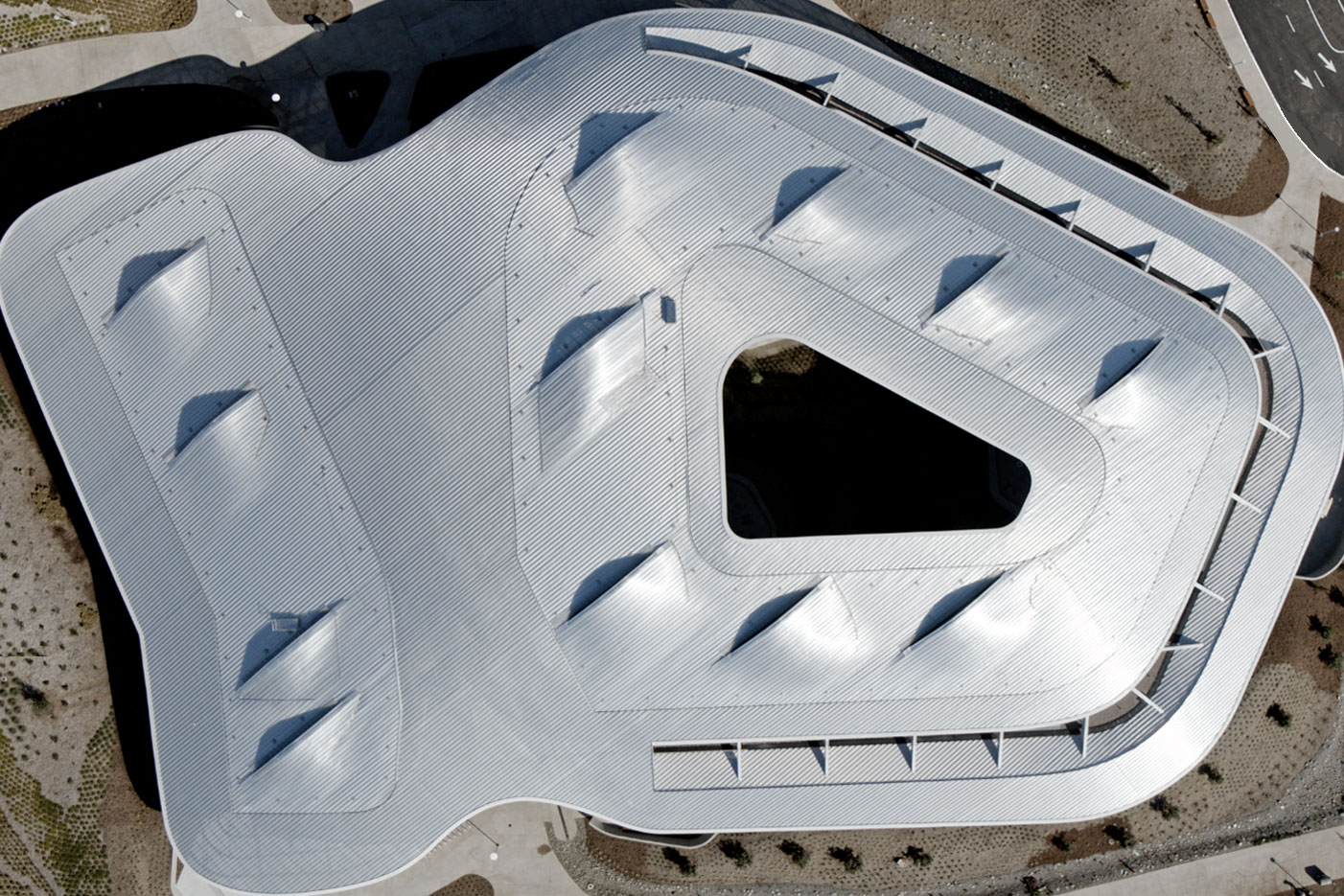

CO Architects topped the Student Services Building at Cal Poly with an undulating, standing-seam aluminum roof that spans over two separate structures. The shape and orientation is driven by performance and function to optimize energy management, maximize daylight, and offer views. Photo by Bill Timmerman

Roughly 30 miles east of LA, a new student services building at California Polytechnic University, aka Cal Poly, provides efficient access to services and a significant upgrade in sustainability. We talked to Associate Principal Architect Alex Korter about the challenges this project faced and how the CO Architects team met them.

The Problem

The breezeway separates the main three-story building from the two-story wing housing the multi-purpose center and human resources department. This arcade leads from the main parking area to the student union and library and is designed to feel like a shaded outdoor street, lined with seating and gathering amenity spaces, while connecting Cal Poly students to the heart of the campus. Photo by Bill Timmerman

The new Student Services Building (SSB) at California Polytechnic University replaces an existing structure that was on the San Jose fault line and deemed cost-prohibitive to seismically retrofit. The university needed to streamline student and administrative functions in one location, and the building needed to perform in the hot climate.

The Solution

The roof required approximately 19,000 attachment clips to keep panels in place. Photo by Nils Timm

CO Architects devised an undulating two-acre aluminum roof that functions as a fifth facade, sheltering building functions and campus activities.

How They Did It

CO Architects devised the Cal Poly roof as the primary performance driver for the curving building to achieve an advantageous Energy Use Intensity (EUI) of 31 (average is 65). Photo by Bill Timmerman

Extensive modeling was used to optimize the roof’s geometry and overhangs to minimize energy loads and maximize occupant comfort, health, and well-being.

To balance shade with good quality daylight and limit lighting energy consumption during the work day, the breezeway roof and overhangs are 18% perforated.

“The building’s roof contour is inspired by the site’s location at the foothills of the San Gabriel Mountains,” Korter says.

The recycled aluminum roof combined with concrete shear walls and Low‐E glass manage heat gain and peak loads, while regionally sourced materials, energy-efficient devices, off-site photovoltaics, and channeled roof runoff and stormwater in vegetated bioswales reduce the heat island effect of the site.

In addition to shading the open pedestrian path between the complex’s two wings, the 90,000-square-foot roof’s perforated metal overhangs vary from 5 to 28 feet deep depending on the orientation to protect the aluminum-framed, low-e reflective glass exterior wall from the sun, filter dappled sunlight, and optimize daylight to the interiors.

To achieve the complex curvatures of the Kalzip standing-seam roof, custom-shaped panels were fabricated onsite utilizing roll-form technology.

The continuous East-West alignment of the standing seams gives the roof texture and grain, while allowing skylights to provide more daylight to the top floor. Standing-seam roofs are rarely as complex.

The Result

A dual-purpose decorative metal band cuts through the central plaza. In addition to adding an artistic gesture, it channels stormwater and roof runoff to a vegetated bioswale, where the water slowly infiltrates into the site’s capture system. This reclaimed water is used to irrigate the new landscape, unburdening the campus’ potable water system. Photo by Bill Timmerman

Digital technology and BIM saved time and created zero waste for the aluminum roof. The project recently achieved LEED Platinum certification.

Korter says the SSB allows the university to consolidate all necessary student services and administrative functions, as it increased space by approximately 70% over the building it replaced.

Additionally, the SSB provides a collaborative and engaging working environment, with built-in flexibility to absorb any future change.

“This building not only successfully responds to the functional requirements, including seismic ones, but also works with its surroundings to enormously exceed the university’s sustainability goals as the first LEED Platinum building on campus,” Korter says. “Cal Poly’s SSB follows CO Architects’ practice of making every project truly of its place, meaning that it could not exist anywhere else.”

Project: California State Polytechnic University

Location: Pomona, CA

Size: 140,000 square feet

Budget: $60 million

Architect: CO Architects

Construction Manager: C.W. Driver, Inc.

Civil Engineer: KPFF Consulting Engineers

Structural Engineer: John A. Martin & Associates

MEP Engineer: Integral Group

Lighting Designer: KGM Architectural Lighting

Landscape Architect: Spurlock Landscape Architects