“We created the healthiest workspace for the office employees but also for their pets,” says Bethany Borel, project architect at COOKFOX. “The IWBI headquarters is a dog-friendly work space, and by specifying no VOC paints, carpet tile, and wood floor stain, the employees can rest assured that the little noses that are closest to those products can breathe easy.” Photo by Eric Laignel

3 Challenges in Designing the First WELL Platinum-Certified Office in the US

Designing to a higher standard is more crucial now than ever, as indoor air quality and office environments continue to be hot topics amidst the pandemic. Last year the International WELL Building Institute (IWBI) moved into new offices in Manhattan’s Flatiron neighborhood, choosing space on the corner of Fifth Avenue and 26th Street in a landmarked, historic building. It is the first, and only as of this writing, office in the US to reach WELL Platinum certification.

IWBI hired COOKFOX for the task. Together their teams maximized the generous air and light of their corner location, carefully chose recycled and low-impact materials, engineered high-filtration air systems, provided healthy food in the kitchen, encouraged active work styles, and emphasized biophilia.

“After years of working in shared and temporary office spaces, it was critical for us to walk the talk and showcase that WELL works for all,” says Liz Miles, project manager for the IWBI office project and vice president of stakeholder relations at IWBI. “We had recently launched WELL v2, and our key goal was to drive equity into the architecture of the standard.”

Miles says the team reduced barriers of entry and offered more flexibility, all while maintaining rigor so that different building types, buildings in various stages with a range of budgets, and buildings in all parts of the world could pursue WELL.

“Our project in particular was a turn-key space in a 1913 landmarked building,” she says. “We had a limited budget and little control over architectural and engineering aspects of the building, but through interior design, operations, and policy, we achieved WELL at the platinum level.”

WELL Platinum requires 80 points and is the highest level of WELL Certification.

3 Big Challenges and How COOKFOX Faced Them

1. Working with a century-old building.

Working with an old building offers up some pleasant surprises. “The gorgeous historical bones of the building reminded us that you never know what you’re going to find when you start removing the layers of paint and plaster that have built up over the years,” says Bethany Borel, project architect at COOKFOX. “Brass and copper double hung windows were still intact, and the riveted steel columns and brickwork were all so well kept under the layers of gypsum. By peeling away the layers and exposing the bones of the building, we read the authenticity of building materials and age.” Photo by Eric Laignel

“Working within an existing historic building is always a unique challenge for ceiling heights and access to daylight,” says Bethany Borel, the project architect and a senior associate at COOKFOX. “With nominally 9’6” to the underside of the beams, we had to be creative about air distribution and lighting. Underfloor air wasn’t an option due to existing egress stair and elevator landings. Dropping a ceiling throughout the space wasn’t an option due to how low that ceiling would have ended up (nominally 7’6” to 8’0” throughout)—which would also significantly block any natural daylight coming into the space. We carefully organized oval ductwork away from the main walking/seating areas. The benefit of the oval ductwork is, the eye reads the space around and above the duct, making the ceiling height seem much taller than the lowest point of the duct.”

2. Landlord and client involvement.

Courtesy of COOKFOX

Borel says, “Working in a multi-tenant building in New York City poses a unique challenge that can be shifted into an opportunity to work closely with the building managers and landlords. Often landlords will deliver a space to their tenant as a whitebox of partial turnkey, but the tenant and their architect have limited control or weigh-in on what materials or fixtures the landlord will be using in the space for their portion of the renovation. We were lucky to have been brought in early enough to work together with the building management group and architect of record to ensure the materials were WELL compliant, and that the fixtures (like air handling units and lighting) had the flexibility to be upgraded to meet the tenant’s certification goals.”

3. Tight timeline.

The lactation room at the new IWBI offices in Manhattan. Photo by Eric Laignel

Borel says the team had only a couple of months to design, vet, and procure products, so their timeline was crunched. Two main strategies helped make sure they met the timeframe and goals.

They worked with vendors who have a dedication to sustainable products—most had already done the legwork of vetting their own materials within the products, so COOKFOX already had the data to support these selections (material transparency, market transformation).

The team reused furniture the client already had and purchased vintage pieces. “This gave the furniture a second life and diverted it from the landfill, while also ensuring that off-gassing had already occurred,” Borel says.

COOKFOX refurbished the existing wood floor, reducing waste and adding natural texture. The carpet is from the Mohawk Lichen line—one of the most sustainable flooring products on the market and the first to achieve the International Living Future Institute’s Living Product Challenge Petal certification. Its biomimetic patterning is inspired by lichen and indicates pathways through the space while dampening sound. Photo by Eric Laignel

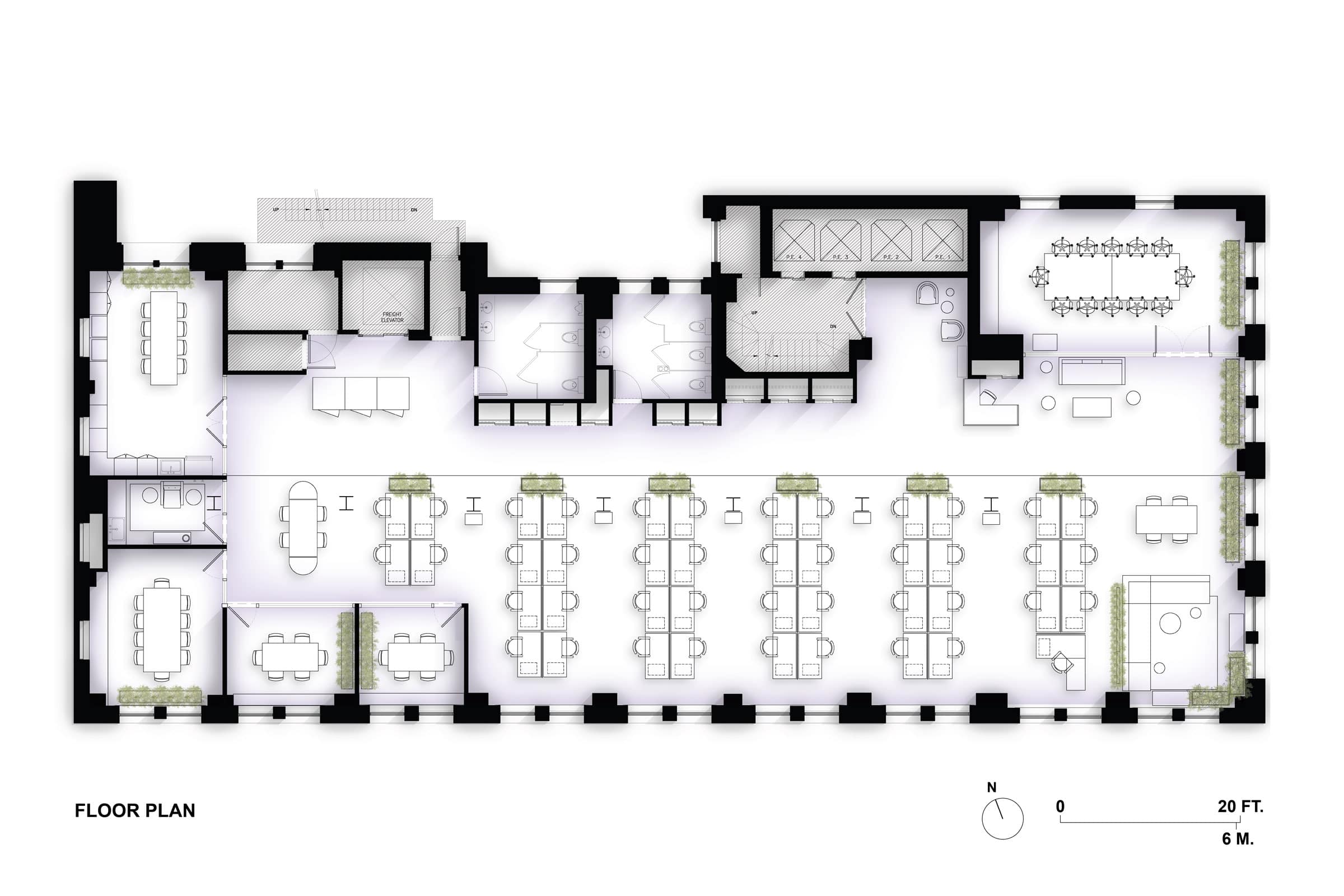

Every workstation has natural light and views to the outdoors, and 50% of the space is dedicated to shared work and gathering areas to support the collaborative nature of IWBI’s workflow. In addition to the sit-stand workstations, COOKFOX designed a variety of workspaces to support different working styles, with the main central desks also convertible from sitting to standing.

The new IWBI office in Manhattan has flexible workspaces with plentiful plant life and natural life. Photo by Eric Laignel

Plants are integrated throughout the IWBI office to help connect staff to nature. “Designed to evoke the positive biological responses of prospecting views from a comfortable, safe place, planter boxes line the windows, drawing the eye outward to the city views and park tree canopy below,” Borel says. “A planter wall shelters the front living room area, and planters interspersed throughout the space act as green screens and add dynamic visual interest.” The building is also just a few blocks from New York City’s flower district. “Once we knew our strategy and planning for the foliage, a few local markets were engaged to fill out the vision.”

Work After COVID-19

Miles says the Manhattan office has more than 40 workstations with about 30 New York–based employees and another half-dozen who commute in on a regular basis. “Pre-COVID, the New York–based employees worked in the office and many of the remote employees visited often and could use the additional workstations. Currently we are all working remotely through the beginning of September 2020, after which we will evaluate an office and remote working schedule that meets individual needs and comfort levels. We are also working closely with the landlord and pursuing our newly launched WELL Health-Safety Rating to implement specific operational policies, maintenance protocols, emergency plans and stakeholder education specific to a post-COVID environment.”

As people began to return to work in the summer, IWBI has already verified several features of their space that can directly contribute to preventing the spread of viruses through its certification. This includes improved air quality through better ventilation and filtration, hand washing facilities to support hygiene and reduce pathogen transmission, cleaning product protocols, and food and water safety.

WELL Certification guidelines are used in 60 countries, and more than 4,100 buildings are now certified or pursuing certification. WELL v2 launched in May 2018.

Project: IWBI Headquarters

Location: New York City

Completion: March 2019

Size: 9,068 square feet

Architect: COOKFOX

Furniture: Teknion

Floor: Mohawk

Certification: WELL Platinum