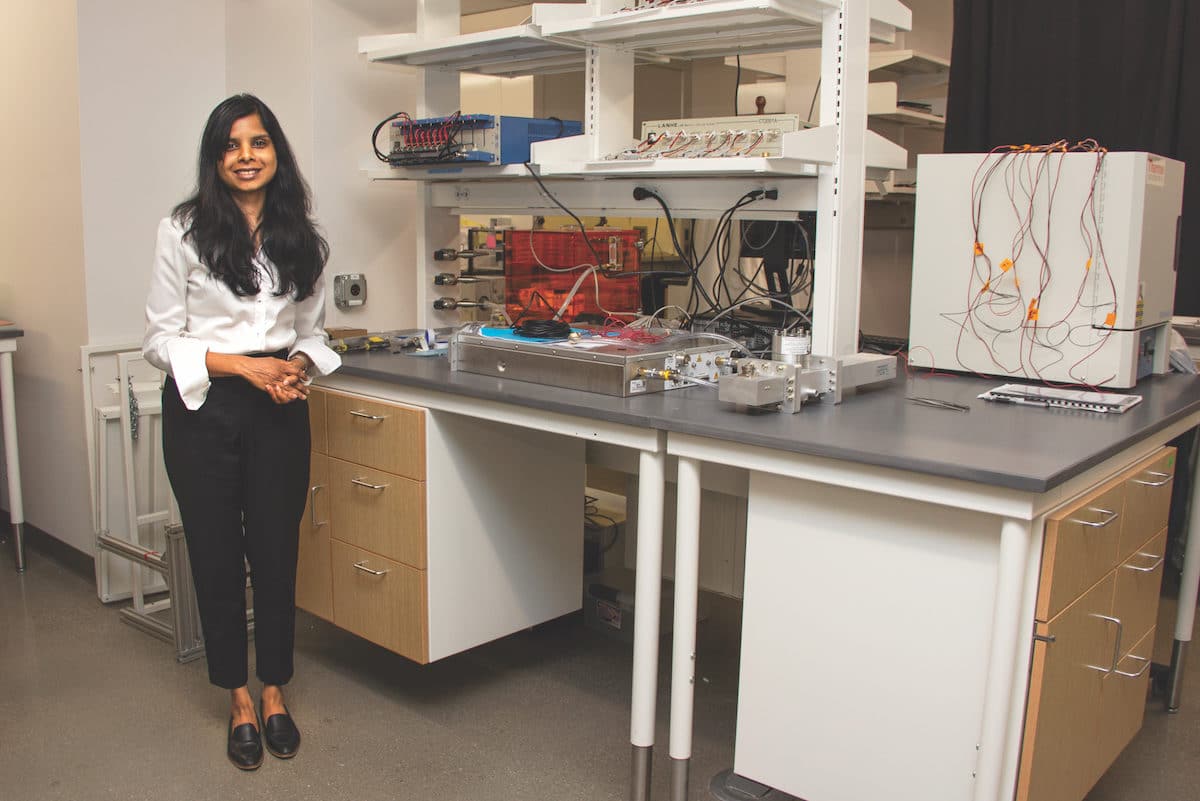

Professor B. Reeja Jayan is developing a process for 3D printing ceramics through her groundbreaking electromagnetic field-matter coupling research. [Photo: Courtesy of the College of Engineering, Carnegie Mellon University]

B. Reeja Jayan, Carnegie Mellon University

Ceramics can withstand extremely high temperatures. As a result, melting them requires a lot of thermal energy, which makes manufacturing ceramics costly and difficult. That’s why B. Reeja Jayan is researching new ways to process ceramics at lower temperatures by using electromagnetic waves.

Being able to melt ceramics easily would decrease the material’s carbon footprint and expand its use and capabilities in the manufacturing industry—from cell phone batteries to prosthetics. Jayan and her team at the Far-From-Equilibrium Materials Lab are also developing a 3D printing process for ceramics to help save time, money, and energy.

gb&d: How are you using electromagnetic waves to further 3D printing technology?

B. Reeja Jayan: Ceramics are materials that cannot be easily melted, so you can’t use current technologies where you use a laser to melt a metal or a polymer and fuse together parts—this approach is not going to work with ceramics. The idea is to look at new science that can enable ceramics to crystallize and grow, and for the particles to come together in a process called sintering at low temperatures.

Electromagnetic fields have been known to realize some of these behaviors at low temperatures. It’s not known why they can do this. Locally, they could be creating extreme temperatures—we don’t know because there’s currently no way to measure these local temperatures precisely. In some cases, depending on the energy provided by the field, there could be coupling with the electronic structure of the material itself.

These questions drive our research on using electromagnetic fields to process materials like ceramics, which conventionally would take a lot of thermal energy to process and build into parts. We hope our finding can enable a type of additive manufacturing or 3D printing process for ceramics.

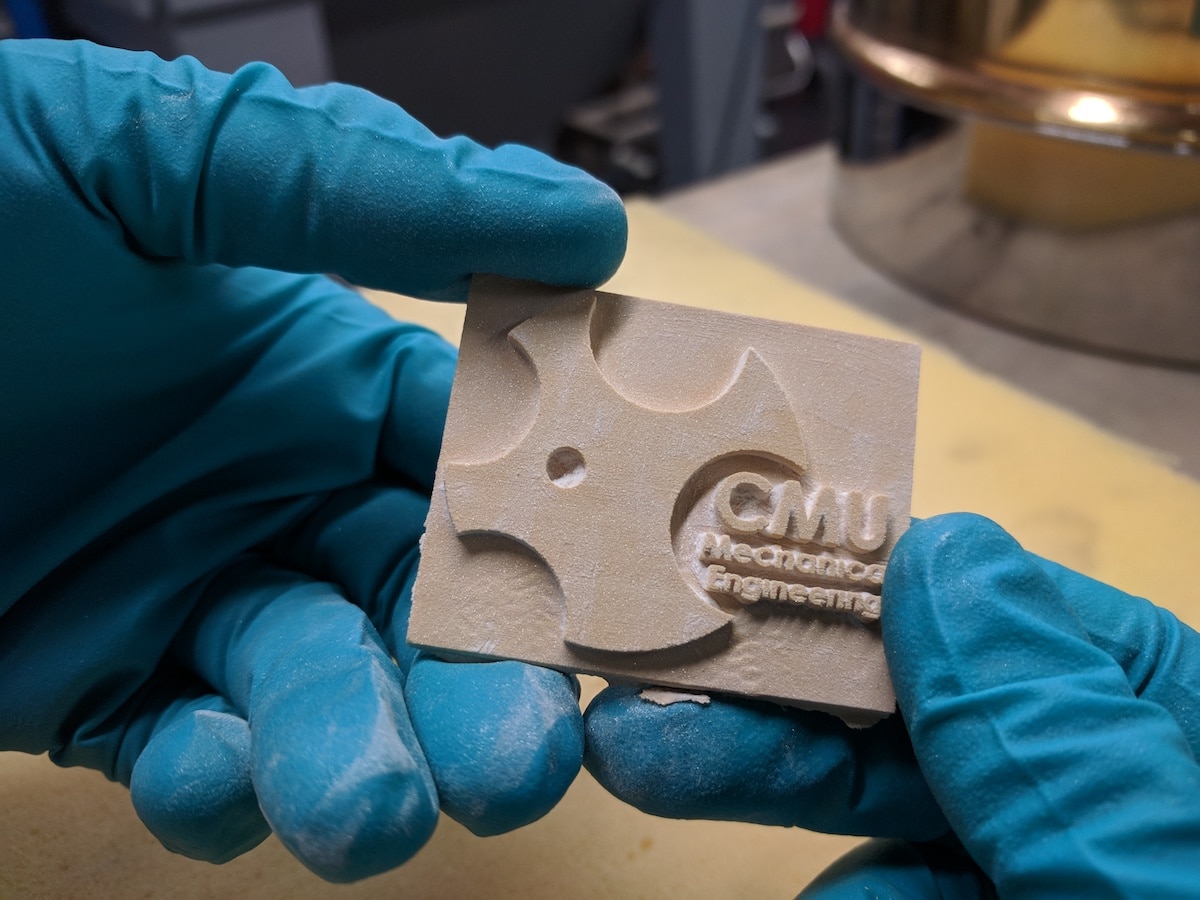

[Photo: Courtesy of the College of Engineering, Carnegie Mellon University]

gb&d: What are some of the practical applications of 3D printing ceramics?

Jayan: Let’s say we could make a printer for ceramics parts. If we can do this at a fraction of the cost, time, and energy conventional ceramic processing requires, then we would be saving a heavy environmental footprint. This is our long-term goal. We are specifically looking at some of these industrial carbide-type materials. There is a joke that while these materials are made in the significant quantities the world requires, some cities and countries are getting polluted heavily. Lowering the energy and environmental footprint is the key need when we push ceramics into emerging applications.

Let’s say for something like desalination or keeping a building or room climate controlled, maybe we can integrate these materials directly into the structure. That way you’re saving costs in terms of the fabrication and you’re getting better functionality. Ceramics are very stable chemically and environmentally. They don’t react or corrode. A lot of times they will last for many years with minimal maintenance. But they require a high-temperature process so you don’t see them getting used in buildings as easily unless it’s a concrete slab. You don’t see them everywhere. We aim to structurally integrate ceramics into existing buildings to add new functionality, but at the same time keep the cost the same.

gb&d: How did you get involved in this research?

Jayan: I have a diverse background in engineering. I was originally an electrical engineer, but I got interested in materials when I was working at the University of Texas at Austin for my master’s degree. I started my PhD in materials, and then when I was at MIT for my postdoctoral training I got exposed to a wide array materials like polymers. Polymers are so easy to process, primarily because they can be easily melted. During my PhD, I worked with ceramics that go into batteries like the ones you have in your cell phone. There, too, we encountered the same problem—you can’t process ceramics at low temperatures.

When I started my independent career, it gave me a unique space to explore because it was such a challenging problem, and a lot of people in conventional ceramics are not thinking in this direction. It helped me bring together a lot of my background to this new problem, including materials science, device engineering, and electromagnetic fields from the electrical engineering experience I had.

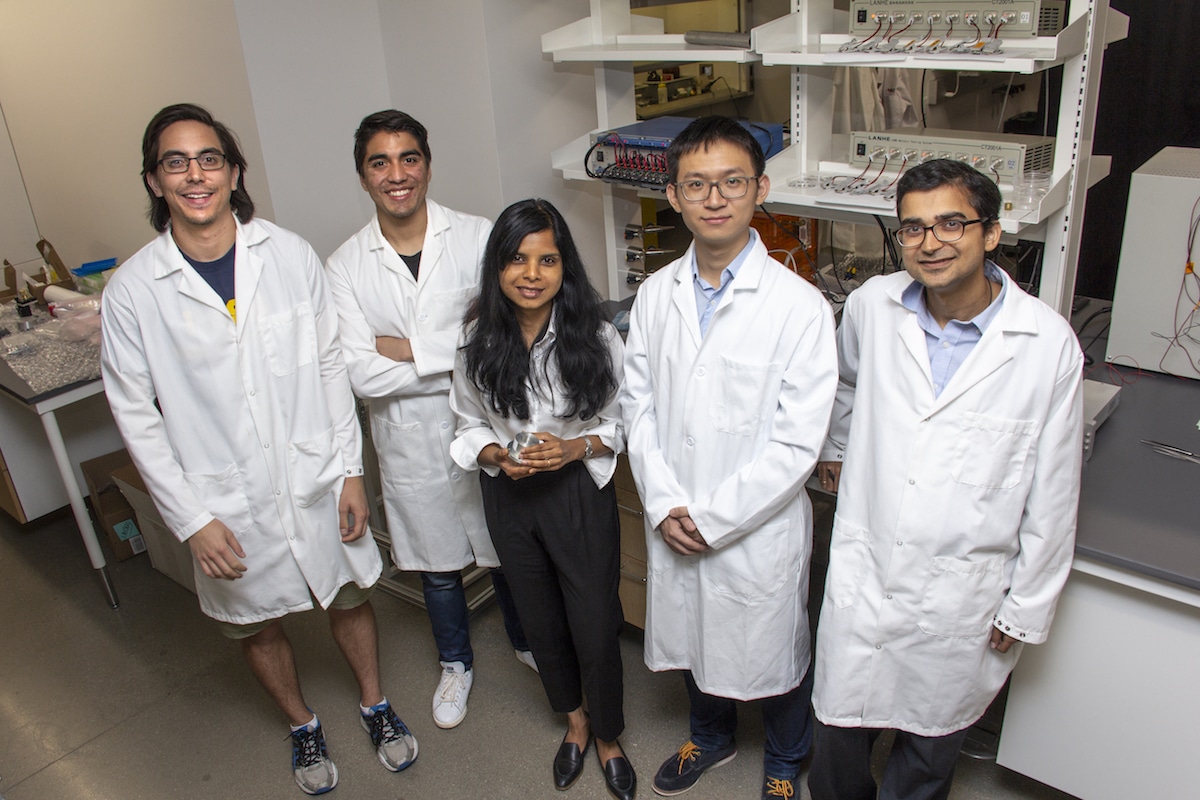

[Photo: Courtesy of the College of Engineering, Carnegie Mellon University]

gb&d: How do you see this research evolving?

Jayan: One of the main ideas we have is to integrate ceramics with polymers. I mean they’re different materials—one melts at really high temperatures and the other melts at low temperatures, so if we could find some sort of midpoint where we could process these together, then we can go everywhere from the structure of a building to maybe the fibers on clothing and start integrating these materials together. That is the interest we have long-term—taking ceramics out of the stone age and bringing them into new age materials, devices, applications, and functionality.

gb&d: Why is the development of ceramic 3D printing lagging behind that of other materials?

Jayan: It’s basically because you can’t melt ceramics easily unlike most materials. If you’re making metal parts conventionally, someone would melt them in a large furnace. The walls of these furnaces are built of ceramics because they don’t melt, even at temperatures where metal melts. Ceramic materials are high-temperature materials. They’re stable. You can’t melt them, so how else do you process them?

The very first instance of making ceramics was back when our ancestors made pots from clay. That’s still almost the same way we process them today. You shape the slurry into a shape and stick it into a furnace at thousands of degrees Celsius.

gb&d: How could modernizing ceramics impact energy efficiency in the building and manufacturing industries?

Jayan: Ceramics have applications in many areas—from prosthetics and dental fillings to electronics. Cell phones have perhaps thousands or more of these components called capacitors that contain ceramics as one of the core materials. Beyond that, some of the materials like silicon carbide are widely used in industrial ceramics. The industries that are making these materials emit tremendous amounts of toxic gases into the atmosphere in places where they are manufactured. If we can find a way to lower the processing temperatures and times and find easier ways to process them, in effect we could decrease not just the energy footprint but maybe even the environmental footprint, especially for materials like carbides and nitrides.

[Photo: Courtesy of the College of Engineering, Carnegie Mellon University]

gb&d: How do you use game-based technology in the classroom?

Jayan: When you make materials, it’s kind of like building blocks. It’s a very hands-on process. A lot of times in class we are not able to help students engage in the hands-on aspect because of the challenges in coordinating lab schedules, and classes are getting larger and larger. I wanted to use Minecraft, the maker-builder game, in the classroom. There are modules where you can build materials. My class uses the building to visualize how a material looks at different scales, from the scale you see it in your hand to the atomic scale. They can immerse themselves in this virtual world and walk around, interact with, and even modify it. They can also build projects based on what they want to do. For instance, one of my students was interested in exploring spider silk and its properties like high strength. He started building spider silk in Minecraft based on different structures he saw online. This gave him some ideas about manipulating the structure and thus properties of the silk, and he decided to go into the lab and try some of these experiments.

Game-based technology is a way to immerse students in really hands-on engineering using a different medium. It’s also a way in which we can test whether learning can be extended beyond the classroom. If my students like it then maybe they will soon start using game technology in more ways in the classroom, without having the pressure of a homework assignment or test.

gb&d: What other significant research is your lab at Carnegie Mellon doing?

Jayan: Our Far-from-Equilibrium Materials Laboratory primarily focuses on using electromagnetic fields to sort of shock a system (material) out of its state of equilibrium. When we do this we get new structures and new properties. Our work on processing ceramics using electromagnetic fields is at the heart of this work.

We also have some fun projects going on in the lab. For instance, I was diagnosed with Celiac disease about six years ago, and I wanted to make a sensor for the protein gluten, which can detect trace amounts of gluten, even in a mixture where there are other proteins present. And that’s hard to do, especially because false negatives are very dangerous to people like me. We have started working on a gluten sensor that’s basically a polymer that changes behavior when it’s exposed to these proteins, and we can pick it up using a device you could plug into your phone. That project is ongoing and we have a lot of interest from the community. We hopefully can expand this sensor to other allergens like nuts and eggs, too, in the future.