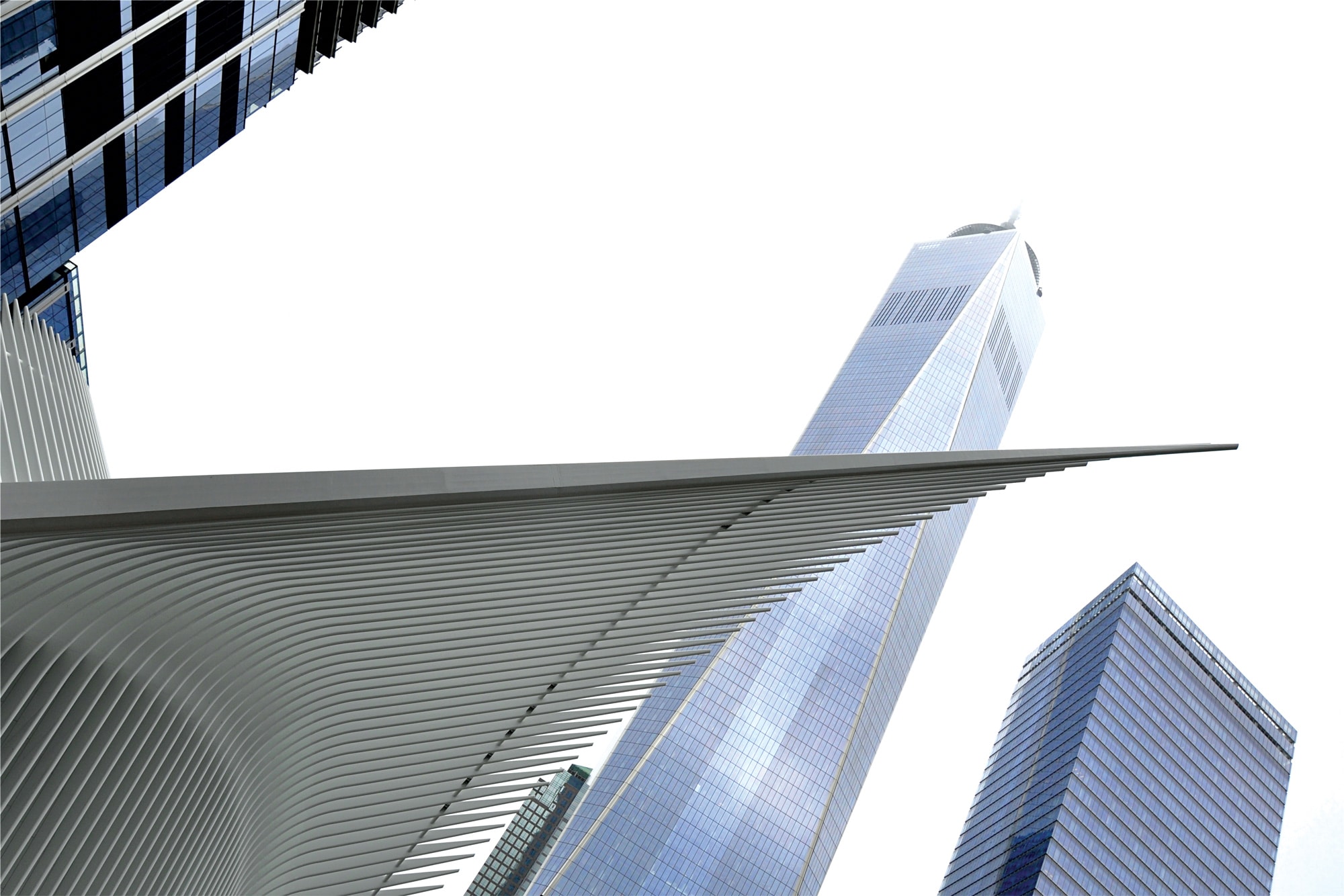

[Photo: Santiago Calatrava]

Download a PDF of this story.

Download a PDF of this story.

To learn more, visit SMDI.

One World Trade Center, the Samsung Headquarters, even a massive mall in Beijing—all are LEED Certified to varying degrees. And while, these days, most people know what it means to be LEED, achieving the certification is ever changing.

LEED v4 was introduced in 2013 and became the sole version of LEED certification available in late 2016. While it’s hard to say whether this update makes it more difficult to earn LEED recognition, new types of credits certainly make the achievement more complex. “The idea is to keep raising the bar, and that was absolutely the intent with version 4,” says Mark Thimons, vice president of sustainability for the Steel Market Development Institute (SMDI). “Architects and builders can get comfortable with a version of LEED to the extent that it’s no longer pushing the bar higher; in the eyes of USGBC, that’s when it’s time for revision.”

Building with steel is one major step you can take to help secure a LEED certification. These are just some of the ways steel can help you rack up those points.

[Photo: Courtesy of SMDI]

1. Recycled Content

Material from steel demolition or construction is easily recycled, with the magnetic properties of steel greatly facilitating its separation from other materials. In fact, steel is 100% recyclable—meaning any steel product can be recycled into another, from a car to a can or even another building. All new steel has some recycled content already. Structural steel is recycled at about 98%, and anywhere from 60 to 80 million tons of steel scrap are recycled every year into new North American products. The sourcing of raw materials recognizes the value of recycled content in materials such as cold-formed steel, and a credit is available for projects where at least 25%, by cost, of the total value of permanently installed building products in the project meet the criteria for responsible extraction.

[Photo: Pixabay]

2. Tight building envelopes

“Steel is dimensionally stable and, when properly designed, can provide an exceptionally tight building envelope, resulting in lower air losses and better HVAC performance over time. This helps to improve the overall energy profile of the building,” Thimons says.

Additionally, insulated metal panels—typically with steel exterior and interior skins—are readily available in a wide range of profiles, textures, and colors. These are essentially sandwich panels that provide excellent insulation for a building’s exterior envelope. “They can provide a very architectural appearance, and at the same time deliver outstanding thermal performance,” Thimons says.

3. Construction and demolition waste management

Steel products can make a significant contribution to this credit, as less construction waste goes to the landfill when you use steel. In fact, all steel framing is 100% recyclable, resulting in negligible steel landfill waste.

Many steel construction products and assemblies are panelized off-site, pre-manufactured, pre-cut to finished size, and/or fabricated to precise project specifications before they are shipped to the jobsite, so on-site waste is minimized. Additionally, steel scrap generated at the jobsite can be easily and economically recycled.

[Photo: Courtesy of SMDI]

4. Flexibility and strength

Design for flexibility, although limited to health care buildings, is another strong attribute of steel. “The nature of cold-formed steel (CFS) framing is that members are typically bolted or screwed together, and structural sections are often bolted, so pieces can be easily disassembled,” Thimons says. “Interior partitions made of CFS can be disassembled and relocated, making it very conducive to future adaptation of the space.”

Its durability goes a long way, too. Just think about when you look up at an exhibit hall or convention center. What do you see? Steel trusses. “Steel is a strong structural material, and steel framing systems are such that you can usually get very long spans between columns. That’s important because it allows for wide open spaces,” Thimons says. “The limited amount of columns allow for more flexibility in the layout of the building’s floor plan. You don’t have to design the floor plan around where the columns are located.”

[Photo: Santiago Calatrava]

5. Heat island reduction

The solar reflectance of steel roofing is particularly valuable for achieving energy efficiency in the heating and cooling of the building, and it’s attainable through the long-lasting durability of coatings that offer optimal solar reflectance for many years. These coatings are available in many finishes, colors, textures, and roofing profiles, tailored to your needs for optimal reflectivity and emissivity. All help to reduce the energy costs associated with air conditioning or heating loads.

In addition to these energy-saving benefits, steel roofs can contribute to a building’s use of renewable energy. They provide the optimal foundation for photovoltaic (PV) installations, since the roof can be expected to last longer than the solar system it supports.

6. Low-emitting materials

The fact that steel doesn’t emit any volatile organic compounds (VOCs) goes a long way. Even painted steel products like roofing are not typically painted at the job site, so they don’t emit VOCs. The VOC emission level is one of the attributes of a product that helps it to qualify for the Health Product Declaration certification. Obviously you want your building to pass indoor air quality testing, and steel will not contribute to the emissions that are required to be tested.

[Photo: Courtesy of SMDI]

7. Building product disclosure and optimization

Mechanisms like Health Product Declarations or Cradle-to-Cradle certification and Declare Labels can all contribute to LEED points, demonstrating a company’s commitment to transparency in its products. “Some of the companies that make steel products will have gone through the process of getting one or more of those certifications, and that would allow them to potentially qualify for those LEED credits as well,” Thimons says.

Similarly, a number of steel construction products can contribute to points by submitting Environmental Product Declarations, or EPDs, compiled from life cycle assessments (LCAs). EPDs are now available for nearly all of the main steel products used in construction, and you can find the full list of EPDs at buildusingsteel.org/why-choose-steel/product-transparency.aspx.

[Photo: Courtesy of SMDI]

8. Raw material source and extraction reporting

Speaking of product transparency, does the company supplying the raw materials for the product publish corporate sustainability reports? The good news is, most North American steel producers do, and thus their materials will help qualify for points. When you use at least 20 different permanently installed products from at least five manufacturers that have released public reports from their raw material suppliers (the report must include extraction locations and a commitment to long-term ecologically responsible land use, among other factors), you’ve achieved one point.

9. Protect or restore habitat

How does steel contribute to preserving an existing habitat where a building will be located? When steel assemblies are panelized off-site or when fabrication of steel framing is completed off-site, the job site benefits from much less on-site disruption, indirectly contributing to this LEED credit.

Read more about SMDI and see related stories here.