Story at a glance:

- Anti-graffiti coatings can help to prevent harmful markings on buildings.

- Depending on the surface, different types of anti-graffiti coatings may be preferred.

- Innovations in technology are giving rise to more effective coatings.

Graffiti removal has become a costly endeavor, with the US spending more than $12 billion on annual cleanup, according to data from MCA-ALPOLIC. Aside from the financial costs, many products used to remove graffiti also contain harmful VOCs that can damage the environment. Pressure washers can use gallons of water trying to strip the paint, and prolonged use can damage the surface.

Anti-graffiti coatings have become an easy and dependable solution to prevent graffiti in the first place.

What is Anti-Graffiti Coating?

The design team behind Toronto’s Evergreen Brick Works decided to preserve the graffiti that had accumulated over the years—but most graffiti doesn’t receive the same treatment. Anti-graffiti coatings make it easy to remove paint-based vandalism without damaging the structure underneath. Photo by Ben Rahn

Architectural coatings are often used to maintain and protect structures or surfaces long after they’re completed. And while there are many types of coatings, anti-graffiti coatings are applied upon a surface in order to prevent graffiti paint from bonding to it.

These coatings create a special, highly cross-linked film between the surface and the paint, preventing staining and allowing for a quick and easy cleanup. Anti-graffiti coatings can be applied by either roll, brush, or spray method, depending on the product line, and are classified based on their longevity.

The best anti-graffiti coatings possess the following characteristics:

- Eco-friendly composition

- Sufficient adherence to a surface without damaging the substrate

- Highly water repellent (hydrophobicity)

- Efficient cleaning process

- Resistance to weathering and UV aging

Types of Anti-Graffiti Coatings

Generally speaking there are three basic types of anti-graffiti coatings: sacrificial, semi-permanent, and permanent. There is also a fourth subtype—nanoparticle—that is really a subset of permanent anti-graffiti coatings, but which operates a bit differently from the others.

Sacrificial Anti-Graffiti Coatings

Sacrificial anti-graffiti coatings create a clear film barrier upon the surface, so if it gets vandalized the coating itself can be easily removed, absorbing the paint and leaving the below area graffiti-free. The materials used for these types of coatings are usually inexpensive and composed of waxes or polymers that form weak links with the surface, allowing them to be easily removed. Once removed they have to be reapplied again, which can cost both time and money in the long run.

Sacrificial coatings are best used on surfaces like wood because they don’t need to be absorbed into the material like permanent coatings do. Sacrificial coatings are also preferred for murals and other artistic surfaces because they are easily cleaned using high-pressure hot water and/or a mild cleaner and won’t gloss over like permanent coatings, a quality that can distort the images and paint underneath.

Semi-Permanent Anti-Graffiti Coatings

Semi-permanent anti-graffiti coatings are high build, most often acrylic, coatings that can shed layers of itself upon each cleaning. Similar to sacrificial coatings, they must be removed but this happens over a longer period of time and can be reapplied once the coating has been completely worn away. Semi-permanent coatings are ideal for surfaces like natural stone walls and historic buildings because they can be easily cleaned using hot water or high-pressure without damaging the material underneath.

Permanent Anti-Graffiti Coatings

The most sustainable of the classes, permanent anti-graffiti coatings only have to be applied once for long-lasting protection. Once vandalized, a simple solvent is often used to clean the surface, stripping the graffiti paint clean and leaving the area below safe and clear.

Permanent anti-graffiti coatings work well on most surfaces and can be either film-forming or non-film-forming. Film-forming coatings can utilize resins from polymers like polyurethane and fluorinated hydrocarbons to create a hard, protective film over the substrate in order to prevent graffiti paint from penetrating the surface. Additionally, permanent film-forming coatings can be layered to create a gloss or matte finish.

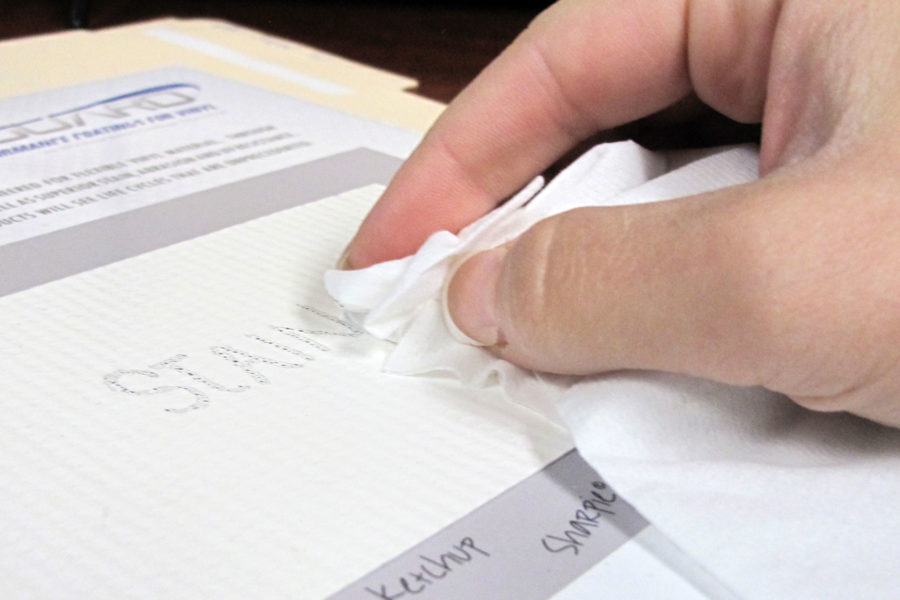

Photo courtesy of APV Engineered Coatings

APV Engineered Coatings‘ VYNGUARD line is a good example of a permanent anti-graffiti coating that creates a film barrier to prevent graffiti plasticizers from migrating into the substrate. These coatings are ideal for metal and plastic surfaces because non-film-forming coatings cannot penetrate those substrates.

The advanced chemistry behind VYNGUARD Anti-Graffiti allows surfaces to resist permanent marker, ketchup, mustard, coffee, blue jean dye, and other tough stains. It is also highly resistant to algae and fungal growth, abrasions, marring, burnishing, and UV degradation, making the finish acceptable for outdoor applications. Once cured, VYNGUARD Anti-Graffiti can accept an emboss without compromising the integrity of the finish. The gloss can be adjusted from ultra matte to high gloss depending on the desired look.

Non-film-forming coatings work to chemically modify the surface tension of the substrate, which can lower the adhesion of graffiti paint, making for a quick and easy cleanup using pressurized hot water. Silicone based coatings can create porous, hydrophobic barriers that allow the substrate to ‘breathe’ while preventing the paint from permanently staining the surface.

Nanoparticle Permanent Coatings

Nanoparticle-based anti-graffiti coatings are a new and innovative type of primary coating that’s growing in popularity. By utilizing a primary binder polymer, reactive and nonreactive silica particles are formed in groups on the surface. Hydrophobic and oleophobic ligands are grafted to the silica resulting in a coating that prevents both water-based and oil-based paints from adhering to the surface. Nanoparticle based anti-graffiti coatings allow for the most proficient protection and have become the more widely used form of pretreatment to date.

Where are Anti-Graffiti Coatings Ideal?

Sacrificial coatings are preferred for murals and other artistic surfaces because they won’t gloss over like permanent coatings which can distort the images and paint underneath. Photo courtesy of APV Engineered Coatings

While anti-graffiti coatings may be applied just about anywhere, they are especially useful in a few key locations.

Murals & Artwork

Anti-graffiti coating is particularly useful in protecting murals and other public art pieces (e.g. sculptures, statues, etc.) from paint-based vandalism. All types of anti-graffiti coating may be used to protect these examples of public artwork, but sacrificial coatings are preferred, as they do not gloss over like semi-permanent and permanent coatings—a quality that helps to preserve the clarity of the art itself.

Public Transit Infrastructure

Some of the most commonly vandalized spaces in high-density cities are transportation depots and their associated infrastructure (think subway terminals, subway cars, railyards, railcars, and the like). Not only are these high-traffic spaces often subjected to conventional paint-based graffiti, but they’re also often the victim of ink- or marker-based vandalism as well.

And while it may not be possible to stop this vandalism at the source, applying a high-quality permanent anti-graffiti coating—one such as VYNGUARD that can withstand a variety of substances—can make the cleaning these surfaces much, much easier, without necessitating the use of strong chemical cleaners.

Tunnels, Bridges, & Underpasses

While it may seem paradoxical that hard-to-reach places are often the target of vandals, the relative inaccessibility of tunnels, bridges, and underpasses makes it more difficult to remove graffiti, meaning tags typically stay up for longer periods of time. Applying permanent, long-lasting anti-graffiti coatings in these places can greatly reduce the effort required to remove any graffiti that does accumulate.

How to Apply Anti-Graffiti Coatings

While not all anti-graffiti coatings are applied in the same way, the below steps are considered fairly universal.

- Prepare the surface. Before applying the coating make sure the surface is both clean and dry; if the surface is unpainted and previously tagged, remove the graffiti first and let dry—if the surface is painted and previously tagged, apply a fresh coat of paint and let dry.

- Ensure proper conditions. Most anti-graffiti coatings must be applied within a certain temperature range, typically 40 to 90℉; it is also not recommended to apply coating on rainy or windy days.

- Gather your equipment. It is usually recommended that a sprayer be used to apply anti-graffiti coating, but most also support roller or brush application; if using a sprayer, adjust tips for a wide spray pattern and only spray at a low pressure.

- Apply the coating. Begin applying the coating from top to bottom using a light spray or stroke until the entire surface is covered; remove any buildup using a damp brush or roller.

- Let dry and apply subsequent coats. After the first layer of coating has been applied, allow it to dry thoroughly before applying a second coat (if necessary); it is usually recommended that at least two coats be applied when covering a porous surface like wood or brick. Allow each coat to dry before applying the next.

- Inspect surface. Once the final coat has dried, inspect to ensure a light, continuous film covers the surface.

As with any product, be sure to carefully follow all of the manufacturer’s instructions and recommendations included with the coating to ensure proper application and protection.

Anti-Graffiti Coatings FAQs

How Much Do Anti-Graffiti Coatings Cost?

Anti-graffiti coatings can vary considerably in price depending on their quality and longevity. On average, however, you can generally expect to pay between $60 and $130 for a gallon of anti-graffiti coating, with sacrificial coatings being less expensive than semi-permanent and permanent coatings.

How Long Do Anti-Graffiti Coatings Last?

As one might expect, not all anti-graffiti coatings have the same lifespan. Sacrificial coatings, for example, aren’t designed for long-term protection—even coated surfaces that aren’t attacked by vandals will typically need to be cleaned and then re-coated after a period of five years to continue providing a barrier against paint-based vandalism.

Semi-permanent coatings, on the other hand, typically have their lifespans measured in the amount of washes they can handle rather than actual years, although you can generally expect them to last at least 10 years before needing to be reapplied.

Even permanent anti-graffiti coatings don’t last forever and will need to be reapplied in order to continue offering protection against vandals. Many permanent coatings tout a 20+ lifespan but may need to be reapplied more frequently depending on how often the surface is vandalized.

Can Anti-Graffiti Coating be Applied to Any Surface?

For the most part, anti-graffiti coatings can be applied to just about any surface commonly subjected to paint-based vandalism, including stone, brick, wood, paint, metal, ceramic and more—just be sure to check the product recommendations in order to verify.

In some cases, however, the question isn’t whether anti-graffiti coatings can be applied, but whether they should. Many state and local historic district commissions—and even the National Park Service—for example, highly caution against using anti-graffiti coatings on historic buildings and monuments due to the potential for either damages or aesthetic alterations.

Matt Noel contributed to this article.