Story at a glance:

- Welded cellular steel deck panels are often not desired for an architecturally exposed application.

- ASC Steel Deck Smooth Series replaces the welded connections in cellular steel deck panels with clean, flush rivet connections.

- Rivet cellular steel deck panels have equal structural capacity to welded cellular steel deck panels while saving resources on projects and guaranteeing clean final look.

Technology has changed the manufacturing of cellular steel deck products, which can be a game changer in many ways. ASC Steel Deck’s Smooth Series™ is an architecturally exposed riveted cellular deck that provides clean beam-to-pan connections by replacing traditional welded attachments with aesthetically pleasing riveted attachments. Smooth Series has equal structural performance to a regular cellular deck with added benefits to your projects for a comparable price. There are challenges with welded cellular deck panels and implications on projects to be aware of. Smooth Series can eliminate those challenges on your next projects.

Welded Cellular Steel Deck

Cellular steel deck is often chosen when a flat appearance on the underside of steel deck is desired. Cellular deck is manufactured from a top fluted section referred to as the beam and a flat bottom section referred to as the pan. The male and female side seam interlock is formed on the edges of the pan. Traditional cellular deck connects the beam to pan by resistance welds in accordance with UL 209. The welded connections are made in each low flute of the beam which result in a nonaesthetic appearance that can be an issue on architecturally exposed cellular deck projects.

There are several downsides to using welded cellular deck panels. Cellular deck is welded in the manufacturing facility from the beam side. This results to inconsistent burn marks at weld locations on the pan which is the exposed bottom side of the panel when installed on projects. The inconsistent burn marks on exposed projects are architecturally displeasing and can’t be avoided when using regular welded cellular deck panels.

After cellular deck is factory welded it is shipped to the job site and stored. Depending on how and the length of time the product is stored, this can result in rusting around welded areas before installation. Rusting around welds is common on cellular steel deck panels but it is important to note that the rusting does not affect the capacity of the panels and only adds to more prep work after installation.

The paint subcontractor must clean all burn marks associated with the resistance welding process upon installation of the cellular deck panels on the project. The painters can only apply paint and primer after the burn marks are cleaned and smoothed down. This process adds unanticipated preparation work for the painting contractors’ costing labor, time, and resources.

For designers the result of an exposed regular welded cellular deck may still be visually unpleasing and unsatisfying leaving concerns that the cellular deck will still look inconsistent on the final project. ASC Steel Deck has a solution for designers—Smooth Series.

Riveted Cellular Steel Deck

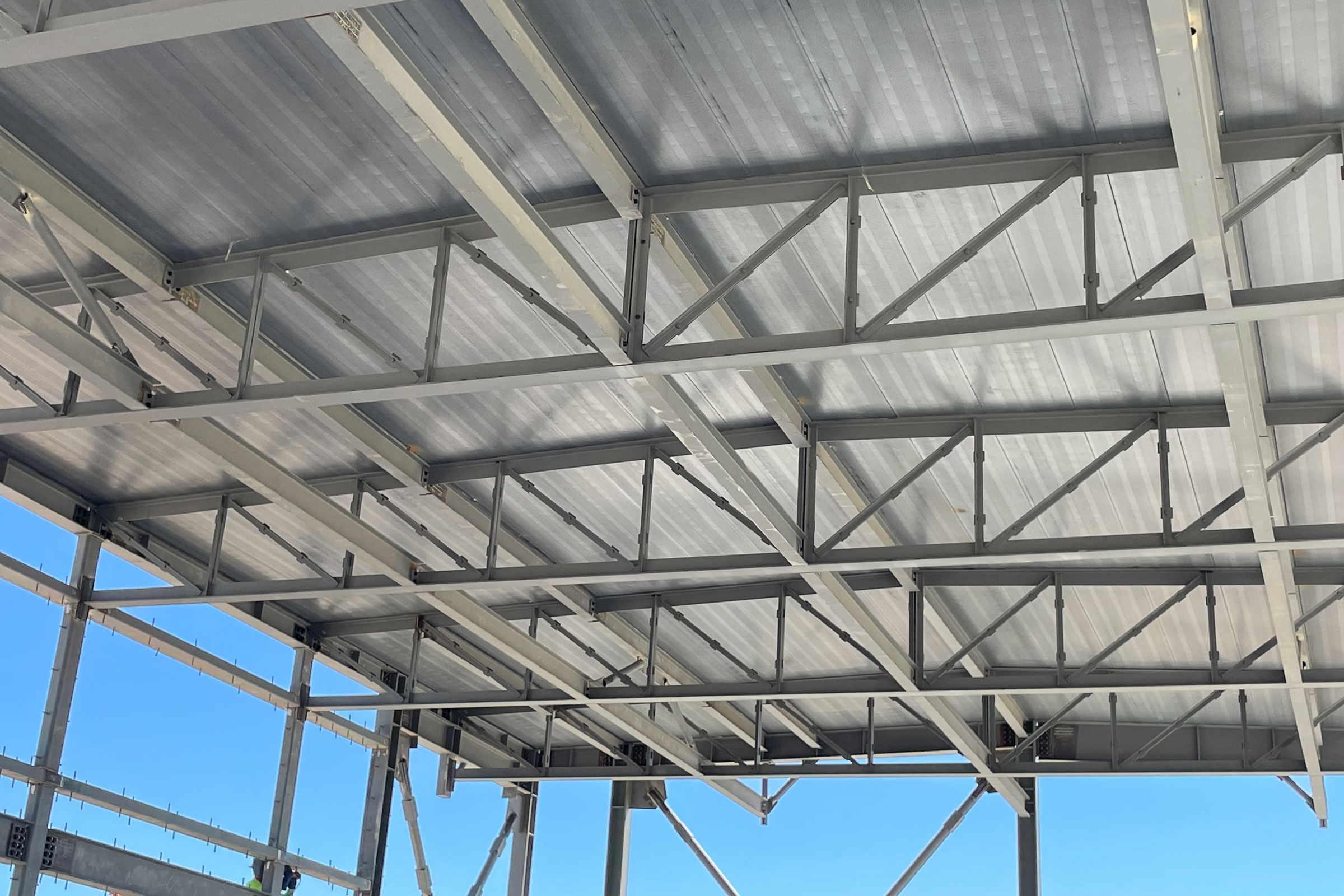

Smooth Series in roof application viewed from bottom. Photo courtesy of ASC Steel Deck

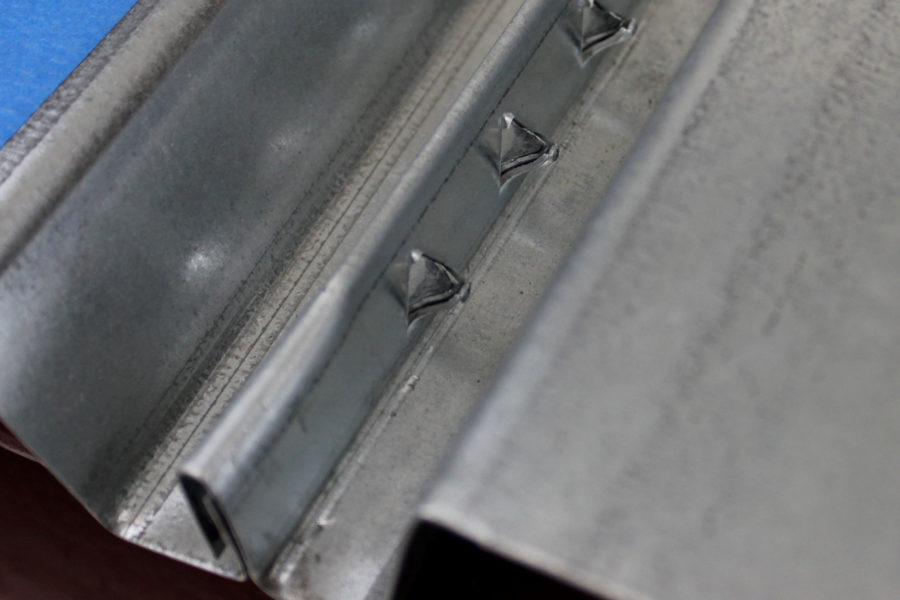

Smooth Series is an architecturally exposed cellular deck that replaces the traditional welded connection with a flush riveted connection. The rivet system is similar to what is commonly used in the automotive industry, which leaves close to no marks on the cellular deck and is hardly noticeable from a distance. The rivet attachment eliminates the bumps and burn marks and the need for touch-ups in the field.

Smooth Series has the same structural capacity as a traditional cellular deck and has an approved third-party verification by the International Association of Plumbing & Mechanical Officials (IAPMO). Section properties, vertical loads, wind uplift loads, and diaphragm shear tables for Smooth Series panels are available in ASC Steel Deck’s IAPMO Report, presented with their equal counterparts of regular welded cellular deck panels. This makes it easy for designers to specify Smooth Series and to substitute Smooth Series for regular cellular decks.

Designers are confident a clean, consistent, aesthetically pleasing, architecturally exposed cellular deck is always delivered.

ASC Steel Deck manufactures cellular deck with Smooth Series rivet connections at its facility, then bundles and ships to job sites. Plated rivets are not susceptible to rusting, which eliminates rust concerns about the riveted cellular deck panels stored before shipment, during shipment, and once delivered and stored on job sites. It is an ideal solution and beneficial for projects in wet climates and projects that may be delayed for extended periods.

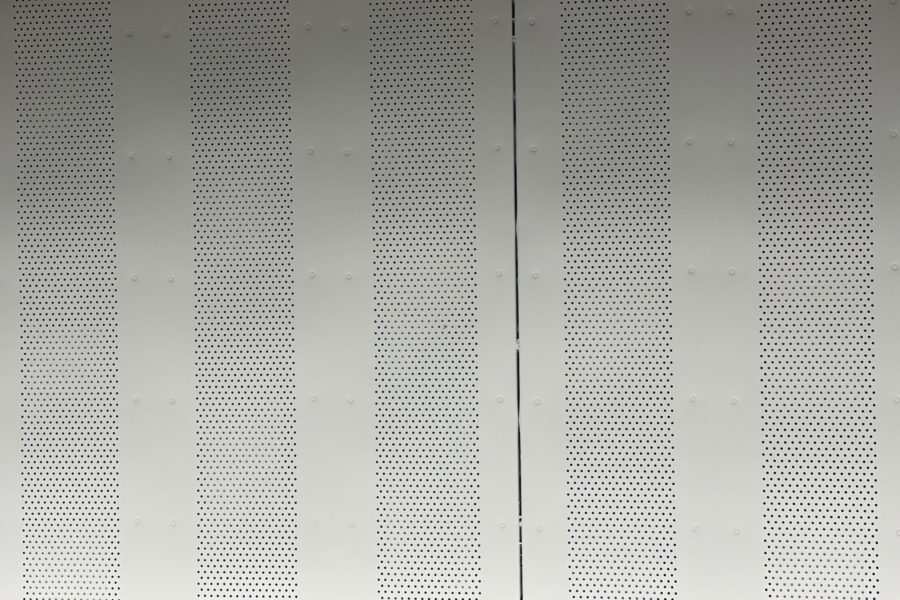

Smooth Series rivets are consistent in size and placement. The rivet heads are 5/16-inch in diameter and connect the beam to pan at 8 inches on center consistently throughout the length of the panel. The consistent spacing creates a uniform pattern on the panels and is hardly noticeable from a distance on an architecturally exposed application, as seen below.

Closeup of riveted cellular deck connection and uniform pattern. Photo courtesy of ASC Steel Deck

After installation of Smooth Series on projects, the riveted connections do not require additional cleaning and field preparation work, as is the case for welded connections, eliminating unanticipated work for the painting contractor, saving labor, time, and resources on the project.

With Smooth Series on the project designers are confident a clean, consistent, aesthetically pleasing, architecturally exposed cellular deck is always delivered. Moreover, ASC Steel Deck can provide transparency documents, including a third-party verified product-specific type III Environmental Product Declaration and Health Product Declaration to support the Smooth Series product offer and gain LEED points on projects.

Smooth Series’ product offering is diverse. ASC Steel Deck offers Smooth Series in a standard galvanized finish option and gray and white factory-applied primer to the bottom side of the panel.

Applications

DeltaGrip sidelap attachment. Photo courtesy of ASC Steel Deck

Smooth Series cellular panels are offered for both roof and floor applications and are available in all B, N, 2 in. W and 3 in. W profile panels. The panels are available for either acoustical or non-acoustical applications. Interlocking sidelap options are available and consist of: DeltaGrip®, Button Punch, and sideseam welded attachments.

DeltaGrip system was developed by ASC Steel Deck to reduce the installation costs of high shear deck diaphragms with costly top seam weld connections. DeltaGrip creates the equivalent strength of a top seam weld with the rapid action of a pneumatically powered DeltaGrip tool. It’s emphasized that the DeltaGrip sidelap option is available for Smooth Series panels. The variety of options available makes Smooth Series a desirable product for designers and specifiers.

DeltaGrip is a pneumatically powered sidelap connection tool. Photo courtesy of ASC Steel Deck

Floor assemblies requiring spray-on fireproofing to the bottom surface of the deck should not use the Smooth Series product. Our supporting UL listing documents this information.

ASC Steel Deck manufactures Smooth Series and ships from the same facility where we manufacture regular resistance welded cellular deck panels. Smooth Series has the same lead time as a standard cellular deck and is priced comparably. Specifying Smooth Series vs. regular cellular deck will ultimately not affect project pricing or delivery time to job site.

ASC Steel Deck’s IAPMO reports, catalogs, and product specifications are all available online and include the Smooth Series product line. You can also find information on UL and LEED supporting Smooth Series products that are available.

Smooth Series has an equal structural capacity to the welded cellular deck and is supported by IAPMO reports. You can get Smooth Series specified on your next project by simply adding the words “Smooth Series” to your next ASC Steel Deck cellular deck call-out. There is no extra work for specifiers to substitute ASC Steel Deck welded cellular deck with Smooth Series. If specifying cellular deck as a general call-out, explore the benefits of Smooth Series for your next project.

Why Consider Smooth Series

Smooth Series is a highly desirable product for all. Architects like it because it guarantees a clean, finished look. Engineers like it because they don’t have to compromise on the structural capacity to deliver an aesthetically pleasing project. General contractors and painting contractors like it because it saves them labor, time, and money for skipping the need to touch up welds and repaint the steel deck. Project owners like it because their project is delivered clean, on time, and on budget.

ASC Steel Deck has completed multiple projects highlighting Smooth Series product line. A notable recent project is a large commercial project including two private office campuses in Northern California where Smooth Series over steel beam framing was designed. This project used a total of 1.3 million square feet of 2-inch W and 3-inch W acoustical and non-acoustical composite floor Smooth Series deck.

Smooth Series during construction of office campus project, finished. Photo courtesy of ASC Steel Deck

Another project to feature is a public works DSA-governed K-8 school project in Northern California where Smooth Series over glulam wood joists were designed. This gave the project a unique look and finish by utilizing more than 47,000 square feet of 2-inch W acoustical composite floor Smooth Series and N acoustical roof Smooth Series.

Smooth Series on K-8 school project. Photo courtesy of ASC Steel Deck

The highlighted projects included a commercial and a public works project requiring California DSA approval. Both projects used ASC Steel Deck’s factory-applied bottom primer to save costs associated with cleaning and prepping for final field-applied paint application. Once noted to building officials that Smooth Series and its equivalent welded cellular deck panel have equal structural capacity per ASC Steel Deck’s IAPMO Report, Smooth Series was given a green light on both projects.

ASC Steel Deck Smooth Series is the clear best option for exposed cellular deck projects. Your project and project stakeholders will benefit from using Smooth Series.