Bamboo has been growing in popularity since the ’90s due to its green nature, aesthetics, and functionality. Bamboo is also fast-growing—it has a regrowth rate of 15 years or less—durable, and a fantastically renewable resource. Plus, bamboo production requires less energy to produce a cubic foot of bamboo material than most other building materials.

That said, different types of bamboo are better suited for certain types of projects. Let’s take a look at the differences in each.

1. Fused Bamboo

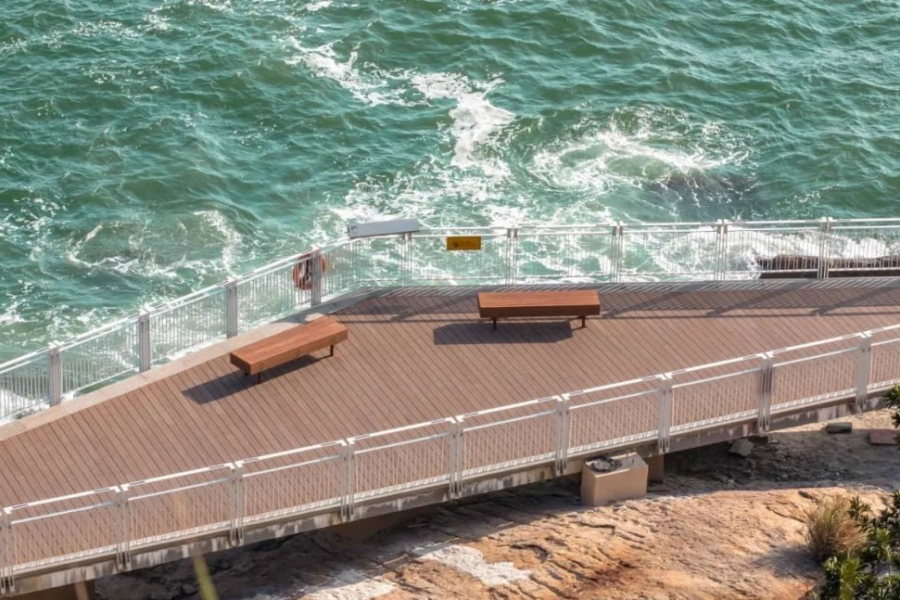

dassoXTR is made of fused bamboo: a type of bamboo that combines wood’s aesthetic appeal with plastic composite’s durability. Photo courtesy of dasso USA

Fourth generation bamboo technology, called fused bamboo, includes the process of getting the strand to specific diameter and isolating of nutrients, either by extracting all the nutrients from natural strand bamboo or by crystalizing the nutrients so that they are no longer nutrients. The strand is then recombined—or fused—after the fiber is encapsulated with what is known as “bowling ball” adhesive—the same product that makes bowling ball.

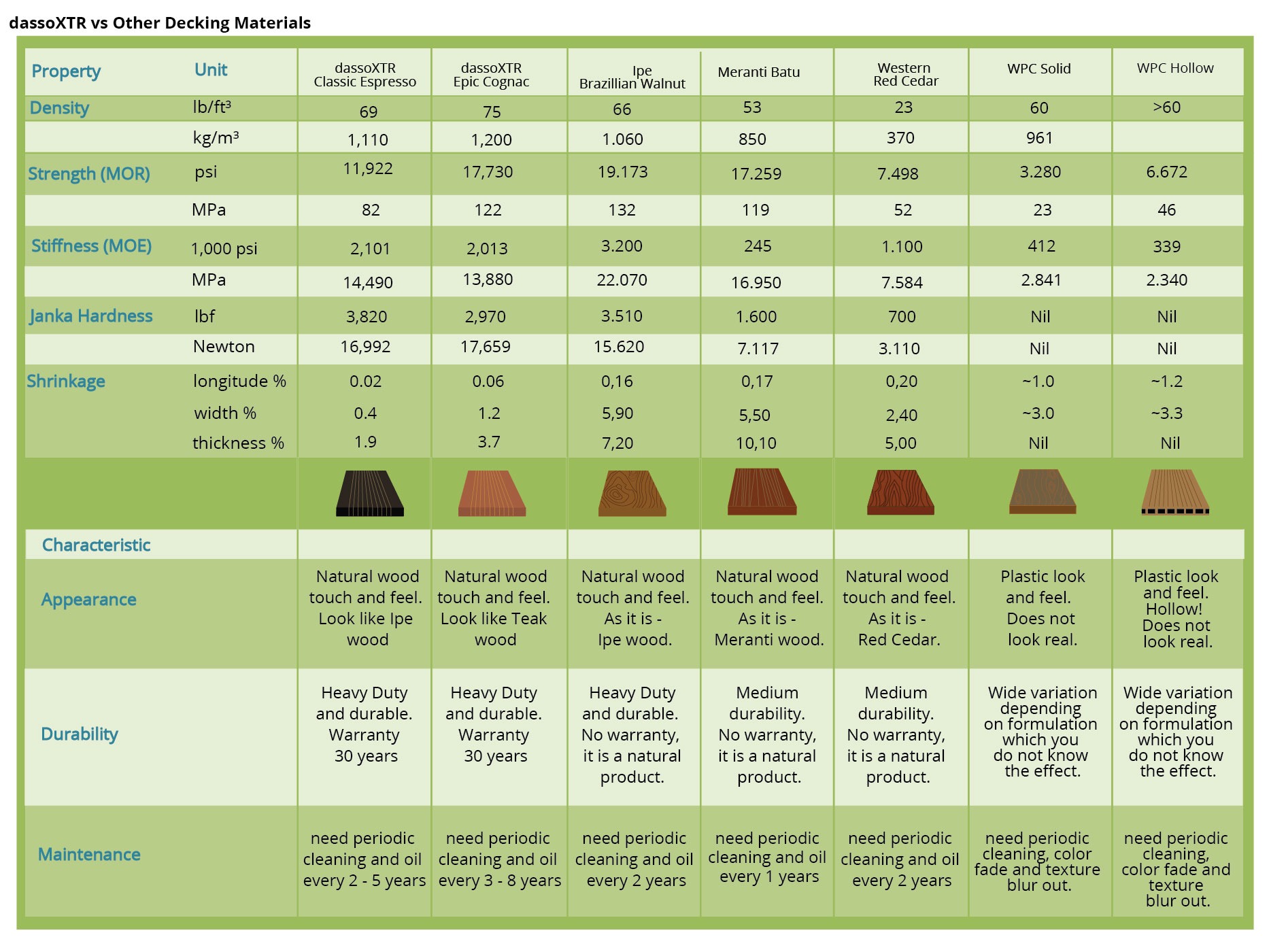

This patented fused bamboo is a hybrid of natural fiber and plastic composite, so it inherits the best of both worlds. It has all the look and feel of natural wood minus the susceptible nature of wood—a short life span, fungus growth, prone to insect and termite attack, rotting and instability. It is similar to plastic composite in that it is low maintenance, durable, and nonrotting in nature. And most of all, fused bamboo does not look like plastic, with a look and feel of natural fiber like any wood.

Without nutrients, the bamboo fiber no longer attracts bacteria, mold, fungus, insects, termites, and a host of other rotting agents. dasso USA bamboo also does not contain any alkaline copper quaternary (ACQ) or chromated copper arsenate (CCA) chemicals—both common chemicals used as preservatives in treated lumber for exterior use—in its bamboo products to preserve fiber. As a result, fused bamboo has no leaching and is safe to use as poolside or in backyard fish ponds. Decking and siding using fused bamboo has also been tested for fire resistance and achieved a Class A Fire Rating and is Wildland Urban Interface (WUI)-approved.

Fused bamboo differs from most wood-plastic composite (WPC) in that it contains a high percentage—87% to be exact—of natural continuous long-strand bamboo fiber that provides the structure strength of the building material. Meanwhile, all WPC uses wood or bamboo dust only as filler and it does not provide any strength to the composite plastic.

Courtesy of dasso USA

2. Unfurled Bamboo

Around late 2006, dasso came up with a new technology to increase yield of bamboo culm. Instead of splitting the culm into strip and square them up or crushing the raw strips into strands, this newer technology simply unfurls and flattens the bamboo culm into a flat sheet of materials under heat and pressure. This process also reduces waste and the need for adhesives.

The unfurled or flatten bamboo culm are then recombined to form various bamboo material. Like strand bamboo, the unfurled bamboo technology does not increase the length of bamboo materials, as the natural taper shape of bamboo culm limits production yield when longer material is produced. Unfurled bamboo materials are great for small household items such as bamboo containers, utensils, and cutting boards.

The most significant difference with unfurled bamboo is the ability to keep the bamboo skin intact, which offers more hardness, elasticity, and strength to the surface, as well as offering a unique look of its own. This surface appearance refreshed the looks and appearance of bamboo.

3. Strand Bamboo

Strand bamboo flooring. Photo courtesy of dasso USA

Another type of building bamboo comes from strand technology, which came into being around 2005. The basic difference in strand compared to strip bamboo is that strand technology creates a harder and stronger building material. This process results in denser, heavily compressed bamboo pieces, which are no longer suitable for horizontal beams because they are too heavy and dense and therefore cannot provide horizontal support.

Strand bamboo is also no longer commonly available in lengths longer than 8 feet, with 6 feet being average, due to the difficulties in keeping the strand together at long lengths during processing. That said, higher yield on the raw material is achieved through strand technology. Due to the limitation to its length, strand bamboo is most commonly used in producing furnishings, household items, and flooring that does not required beams longer than 6 feet.

4. Bamboo Strips

Photo courtesy of dasso USA

Bamboo was first industrialized in the early 1990s with strip technology, where bamboo strips are use as basic building block. In this early technology, bamboo culm—or the stalk—is cut into strips and then squared off to form a long strips, which are then glued together.

This bamboo strip technology is commonly used as a wood replacement such as in bamboo flooring, sheet goods, posts and beams, furnishings, and veneers. This bamboo technology is great for interior usage but is not suitable for exterior use, as bamboo strips still contain a huge amount of nutrients that can attract rotting agents like mold, fungus, and insects, especially in high-humidity environments. The bamboo material will also still expand and contract during extreme temperature changes, which can cause splits in the natural fiber.

In closing, we see great value in using sustainable bio-based bamboo materials. With the look and feel of natural material and the low maintenance of composite material, you can’t go wrong.