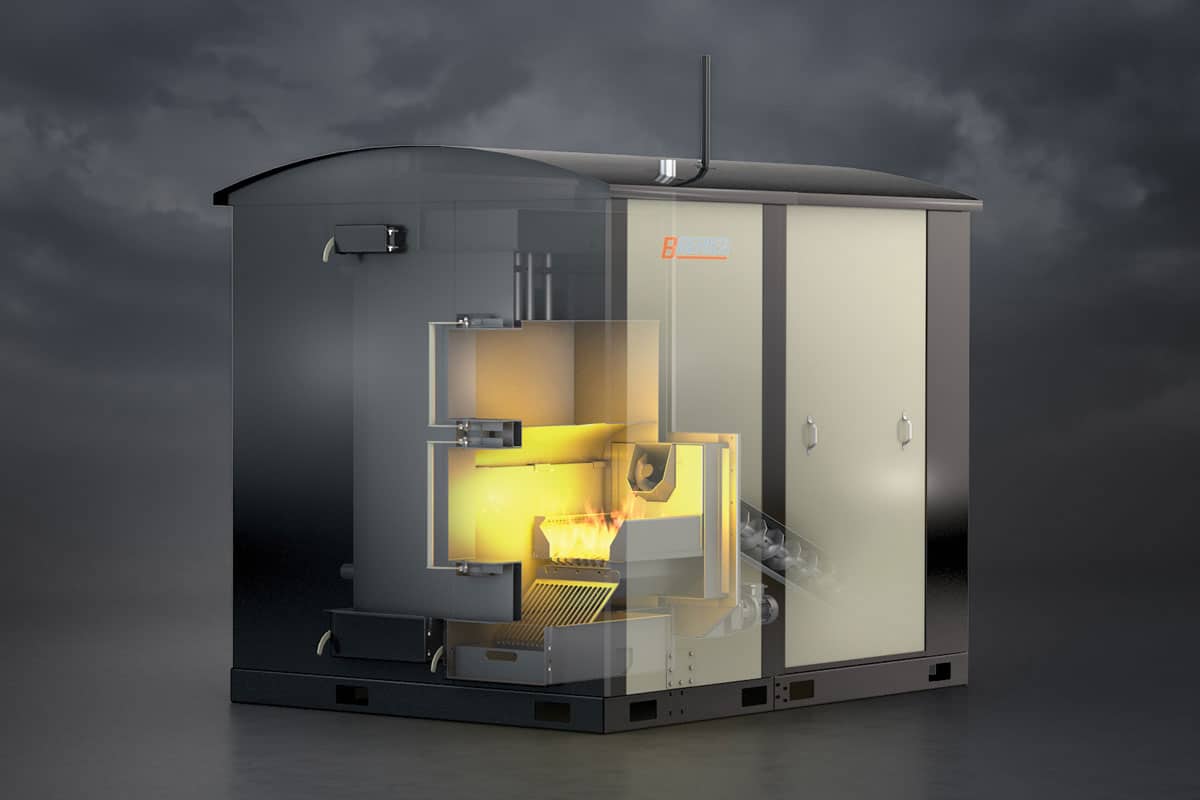

[Photo: Courtesy of HeatMasterSS]

HeatMasterss is revolutionizing heat delivery with simple but smart solutions.

In Manitoba, Canada, a family-owned company called SteelTech Inc. under the brand name HeatMasterss has been manufacturing outdoor furnaces since 2001—pushing the envelope with innovative products and setting an example in the industry to do better. While their previous outdoor furnace models primarily burned wood byproducts, the existing technology presented a problem. “The focus on burning wood and all of the emissions that result from that process was troubling to us and our customers,” says Blair Groening, head engineer at HeatMasterss.

Thus, the B Series Multi-Fuel Biomass furnaces from HeatMasterss were born—changing the way large spaces are heated and educating the public on the benefits of using alternative fuels. The compact size, touchscreen controls, and hands-off automation of the B250 makes the model an excellent fit for any homeowner, while the B500 and B1000 are geared toward commercial and industrial applications.

The engineering team began developing the B Series based on extensive feedback from customers. These included numerous upgrades to digitize and automate the process while helping the machines achieve carbon neutrality. And unlike previous models, the B Series can burn wood chips, pellets, agricultural screenings, and more. “There’s a long list of fuels the R&D department is working on, including egg shells, manure products, cherry pits—you name it,” says Jake Friesen, founder and CEO of HeatMasterss. “We want our customers to be able to utilize any potential fuel that’s available to them.”

While HeatMasterss continues to upgrade its offerings, the benefits of the B Series are easy to see.

[Photo: Courtesy of HeatMasterSS]

1. Diverse Applications

Due to the flexibility of hot water as a heating source, the B Series can be used for residential, light commercial, and heavy industrial scenarios. “Whether it’s a warehouse, a pool, or a manufacturing facility, you can do it all

with hot water, which is a universal heating application,” Friesen says.

Groening says the team is always finding new ways to utilize this carbon-neutral heat. “Buildings at construction sites are often heated with diesel, which ends up using hundreds of gallons of fuel on a given site. With a wood chip application, you’re heating at a fraction of the cost and bringing down your carbon footprint as well,” he says.

[Photo: Courtesy of HeatMasterSS]

2. Environmentally Friendly

Traditional biomass furnaces are rather simple machines, designed around a system of wood combustion that’s used to heat water. However, anyone who’s stood near a campfire understands the negative effects of burning wood products. The HeatMasterss team poured resources into developing more efficient technology in which combustion occurs in a controlled environment with very high temperatures.

By optimizing the fuel burn rate and fine-tuning the level of combustion within the furnace, the B Series burns as clean and efficiently as possible. “We’re able to achieve a lot more energy out of the same amount of fuel, with a fraction of the emissions,” Groening says.

[Photo: Courtesy of HeatMasterSS]

3. Quick Return on Investment

Utilizing alternative fuels for heat isn’t just environmentally friendly. “It has a very logical return on investment from a cost perspective,” Friesen says. For example, Friesen explains burning wood chips costs about one cent per kilowatt of energy, compared to anywhere from 10 to 20 cents per kilowatt with natural gas or other fossil fuels. At this rate of energy savings, the B Series quickly pays for itself and lowers energy bills throughout the life of the furnace.

[Photo: Courtesy of HeatMasterSS]

4. Energy Independence

Utilizing alternative fuels for heat isn’t just environmentally friendly. “It has a very logical return on investment from a cost perspective,” Friesen says. For example, Friesen explains burning wood chips costs about one cent per kilowatt of energy, compared to anywhere from 10 to 20 cents per kilowatt with natural gas or other fossil fuels. At this rate of energy savings, the B Series quickly pays for itself and lowers energy bills throughout the life of the furnace.

[Photo: Courtesy of HeatMasterSS]

5. Ease of Use

The fully automated B Series solves one of the major problems that has stifled the widespread use of outdoor furnaces—reducing the intensive labor involved in loading fuel materials into the machine. “With our previous models, some of the responses from

our customers were that the process involved too much work, and many wondered how we could automate the process,” Friesen says.

The fuel is delivered from the truck to the fuel storage bin with conveyors, and from there the fuel is automatically loaded into the furnace and burned based on the customer’s desired temperature setting. The ash is also cleaned from the unit automatically, and advanced safety procedures prevent the fire from burning back into the storage bin.