Story at a glance:

- Fiber has the largest environmental impact of any component of carpeting.

- Universal Fibers was the first company to incorporate pre-consumer recycled content and develop the world’s first carbon-negative fiber.

- In partnership with the Carpet America Recovery Effort, Universal Fibers has diverted more than five billion pounds of carpet from landfills.

Fiber causes more impact on the environment than any other part of carpeting. That’s why scientists at global carpet fiber producer Universal Fibers responsibly spent the past 50-plus years making its products as sustainable as possible without impacting aesthetics, performance, or functionality.

“Fiber choice matters—from the sheer volume of its environmental impact to its role as the stage-setter for design,” says Ranae Anderson, global sustainability leader for Universal Fibers. “As the foundational element, carpet fiber choice conveys the emotion of a room through its texture and color.”

Yet the emotional resonance of Universal Fibers products doesn’t stop at look and feel. “We also want our customers to know they are making smart choices for our planet,” Anderson says. “We’re mission-driven to create products and implement processes that use more recycled content, cleaner energy, less water, are sourced responsibly, and continuously lower our carbon footprint. First-evers in sustainability progress remain Universal Fibers history and future.”

Photo courtesy of Universal Fibers

The company was the first to incorporate pre-consumer recycled content (also known as post-industrial), and the first to create the world’s only carbon-negative nylon fiber Thrive® matter, launched in June 2021.

Universal Fibers believes partnership and collaboration are mission-critical. Since 2006 the company has been a committed and highly active participant in the Carpet America Recovery Effort (CARE), a nonprofit organization advancing market-based solutions that increase landfill diversion and recycling of post-consumer carpet while encouraging the design for recyclability. At the time of this writing, CARE has prevented five billion pounds of old carpet from ending up in US landfills. “This equates to about 15 pounds of carpet for each person in the US,” Anderson calculates.

A fierce champion of environmental stewardship, Anderson recently shared her thoughts with gb&d on the role fiber has in creating sustainable spaces.

Why should architects and designers pay attention to fiber?

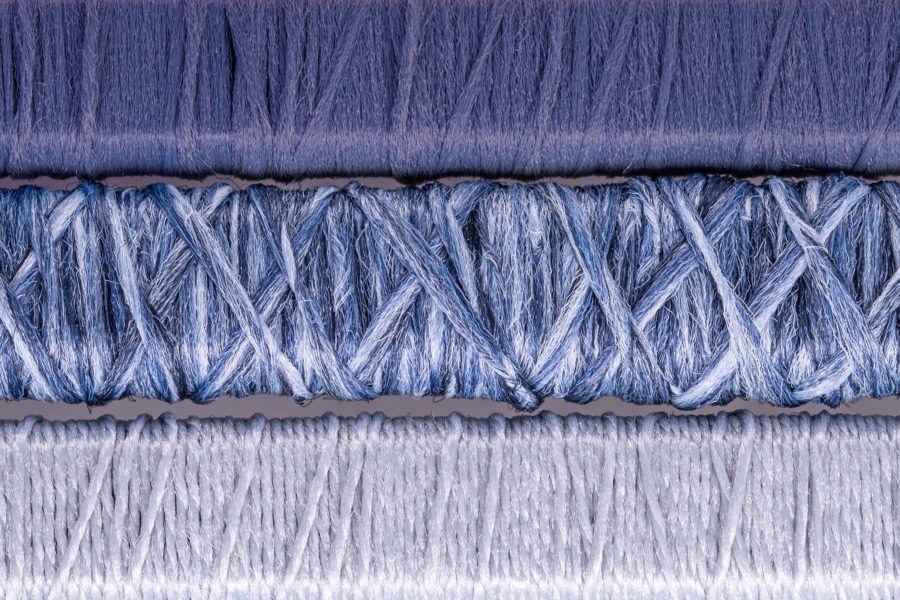

Closeup of Universal Fibers carpet fiber. Photo courtesy of Universal Fibers

It’s natural for architects and designers to pay attention to fiber because it’s the part of the carpet you see and feel, but fiber also impacts the environment more than any other carpet component. Think about the fact that one tree absorbs about 48 pounds of carbon a year. There are 26,000 trees in Central Park. Our Thrive fiber versus virgin material can match the carbon absorbed by 30,000 trees a year—more trees than there are in Central Park. That’s what makes Thrive fiber a highly effective choice for sustainable design.

Eco-responsible designers should also question how the product is colored. At Universal Fibers, we use a solution-dyeing process that not only has many performance advantages but also uses virtually zero water. We’ve been using this coloration method since the early 1970s. This process has saved more than one liter of water for each of the 7.7 billion people on the planet. The enormous amount of water saved by this process becomes more impactful each year.

What is the carbon footprint of carpet fiber exactly?

Photo courtesy of Universal Fibers

I want to make sure we mean the same thing when saying carbon footprint. In this case we mean the amount of carbon emitted through manufacturing.

If virgin material is used to make the nylon 6,6 fiber, roughly 9.5 kgs of CO2 is emitted for every kilogram of fiber. Our Thrive product, which came to market in 2016 and won the Best of NeoCon Innovation Award, had a carbon footprint of 3.66 kgs, making it the world’s lowest carbon footprint nylon 6,6.

But our team did not stop there. In 2019 we reduced it to 3.33 kgs, then continued to innovate and lowered it further to 2.52 kgs, then 2.2 kgs. We then achieved a whole new level by going carbon-negative with our Thrive matter product. It continues to be an evolutionary process of which we are very proud.

How do Universal Fibers’ products hold up long-term?

This is an example of different fiber finishes with the same colors. Photo courtesy of Universal Fibers

There are no trade-offs with our products. With proper care and maintenance our fibers should hold up for many, many years. It is more likely that a person will look to refresh a space long before the carpet begins to wear down. The average life cycle for carpet in corporate offices or other high-traffic areas is five to seven years.

Many variables play into the exact time the product will last, like fiber chemistry, finishing, pile height, backing, and how our customers construct it in tufting. Depending on these variables, a service life of 10 to 12 years or more isn’t unreasonable.

Carpet warranty standards outlined by the Carpet and Rug Institute have very specific care and maintenance guidelines. If those are followed we believe that since the color is built into the fiber during the solution-dyeing [melt coloration] process, and we include an effective stain-resistant additive, the fiber can be warrantied for even longer if needed.

What happens at the carpet’s end of life?

We work with our customers to transition the used carpet for a second life. The components may be recycled back into new carpet or used as raw materials in another industry. For example, the automotive sector values nylon 6,6 chemistry for use as a high-heat exposure component under the hood.

We are a global company, fully integrated from color concentrates and fiber extrusion to finished yarns in multiple chemistries. This includes Nylon type 6, or 6,6, and various other polyesters. We serve carpet manufacturers in commercial, residential, and automotive segments, as well as 14 additional markets. We are the only global solution-dyed fiber manufacturer that produces such a diverse selection of products. It sets us apart from other manufacturers.

I love talking about the different applications where you can find our materials. Ever been in a car, truck, or van? That’s probably our fiber underfoot. Our strength lies in our diversity. You can find our fiber in parachutes and in military applications like thermal base layers, conductive filaments, composites, and filtration. Many people don’t realize this, but you may have even tasted our product by using dental floss made with our fiber. Our products are used in other medical applications as well. My point is: Our products go beyond the carpet fiber industry.

That’s a lot of fiber, so we must consider what we are leaving behind. We want to make sure we leave things better than we found them in the community, with our customers, and with our families.

What about aesthetics, comfort, and noise dampening?

Choose a wool-look product that looks and feels shorn from a sheep but surpasses natural wool with the durability of a solution-dyed nylon product. Photo courtesy of Universal Fibers

Flexibility in design matters a lot. That’s where our experience comes into play. Having a winning team enables us to deliver that flexibility. Our expert colorists seemingly perform magic, and our product development team conjures new products daily with unique finishes and aesthetics. They found a way to create a wool-look product that looks and feels shorn from a sheep but surpasses natural wool with the durability of a solution-dyed nylon product. We also have products that lead the industry with high-bulk and low-weights. These provide better coverage, easier cleaning, and increased comfort while saving on shipping and storage costs. We love experimentation and eagerly accept challenges presented by innovative designs. We can quickly customize, based on a customer’s specific needs and objectives.

Our products can reduce noise in a space by as much as 70%. Carpeting absorbs ambient noises and reduces echo. Depending on the pile height, fiber can dramatically assist in insulating the surface temperature of the floor and the room, which can be highly beneficial to those of us who are sensitive to temperature changes. In summary, the right fiber in carpeting adds to beauty, form, and functionality while providing a sustainable legacy to be proud of.