Story at a glance:

- The AEC industry has a history of ventilating by bringing in more outdoor air that then has to be conditioned, effectively over-ventilating, according to some experts.

- New from ASHRAE, Standard 62.1 specifies minimum ventilation rates and other measures intended to provide IAQ that’s acceptable to human occupants and that minimizes adverse health effects.

- A new solution from GPS Air launching in December 2024 recognizes building and occupant air quality patterns, sensing when contaminants of concern, such as VOCs and fine particles, are introduced—automatically responding to clean the air.

Updated indoor air quality procedures from ASHRAE (Standards 62.1 & 62.2) is making it easier to have good, clean air and reduce risk, cost, and energy, according to GPS Air, a top IAQ solutions provider.

ASHRAE’s 2030 vision hopes for a built environment that provides resilient, livable, and beautiful places to live, work, shop, and commune with people. Transforming new and existing building stock is necessary to ensure a decarbonized future, according to GPS Air, who is focused on reducing the energy burden of conditioning air while improving indoor air quality.

“Years ago energy efficiency and indoor air quality were diametrically opposed,” says Tracy Stoner, special project manager at GPS Air. “You couldn’t have good indoor air quality without paying a premium for it with larger equipment and higher operating costs.”

Today that’s simply not the case—and there’s no excuse not to have both.

Inside the New Standard

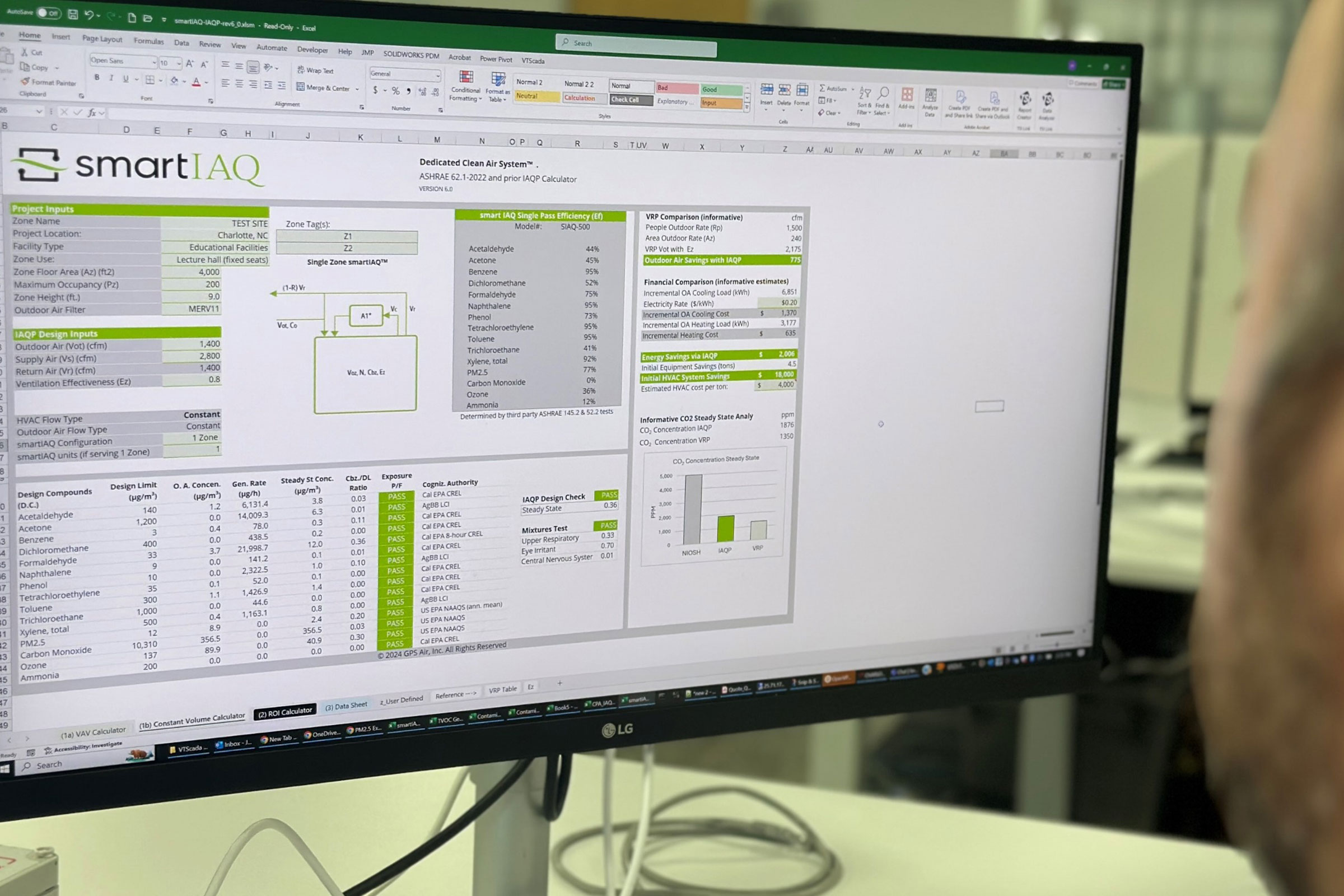

A new solution from GPS Air launching in December 2024 recognizes building and occupant air quality patterns, sensing when contaminants of concern, such as VOCs and fine particles, are introduced—automatically responding to clean the air. Image courtesy of GPS Air

Implementing the new Indoor Air Quality Procedure might be the single largest equipment and energy-saving opportunity not being widely considered, Stoner says. When applied to education, office, and multi-use spaces, the procedure reduces required outdoor air by as much as 60%, according to GPS Air. It can also simplify HVAC equipment and reduce cost on both new designs and adaptive reuse projects, saving up to $2 per square foot on annual energy costs, according to GPS Air. In fact ASHRAE’s own 62.1-2019 user manual describes the procedure in this way: The IAQP may allow for a more cost-effective solution to providing good air quality.

“The new standard allows designers to leverage design elements in a very meaningful way so you can both produce a good indoor environment for building occupants as well as do it in an energy-efficient manner. This has only been in the last year or so as the standard has evolved,” she says. “Conversations now are more open and amenable to the two of those working in a symbiotic way.”

Where you used to have to bring in large quantities of air, cool or heat it, and increase equipment size or building infrastructure to support it, today’s carbon footprint can be much smaller and the whole process can be a lot simpler, Stoner says. This is where an innovation launched in late 2024—the smartIAQ™ Dedicated Clean Air System™ —comes in.

New Solutions

Photo courtesy of GPS Air

GPS Air’s new smartIAQ Dedicated Clean Air System is an autonomous, demand-driven air cleaner for the design compounds, or contaminants, ASHRAE lists in 62.1. “It is a device that does one thing; it cleans your air, on demand, responsive to the onboard air quality sensors to determine when it’s time to work and how much air it needs to clean,” says GPS Air CEO Audey Cash. A revolution in sensors in the last five years allows the new system to measure air quality and react in real time. But you don’t have to interpret the data yourself; the system does it for you.

smartIAQ quietly operates based on advanced sensing trained to recognize building and occupant patterns, accelerating air cleaning when needed and idling when unoccupied, thereby extending filter life and lowering maintenance. Onboard filtration offsets outdoor ventilation, ensuring occupants breathe clean air with minimal sound and maintenance.

Thoroughly designed for easy installation and deployment, smartIAQ is compatible with in-space supply and return diffusing systems to seamlessly fit into any design. Because smartIAQ recognizes patterns and air quality risks, it only operates when needed, remaining virtually silent most of the time, and operating quickly and quietly when its advanced sensors detect contaminants of concern, for example. “It’s quiet, and it’s out of sight, out of mind,” Cash says.

With plans to begin shipping in December 2024, the system is an evolution of thinking—instead of large dedicated outdoor air systems (DOAS) for massive ventilation, balance smaller outdoor air approaches with a dedicated clean air system that targets contaminants to ensure indoor air quality is met with comfortable HVAC operation. “All of this at a fraction of the first cost,” Cash says.

“I liken it to daylight harvesting. In lighting if there’s enough outdoor sunlight, that’s free energy, that’s free illumination. You can shut your indoor lights off. Same idea here—if you don’t have enough contaminants that it’s a concern, you don’t have to run the unit as hard. It’s a fully variable system.”

It addresses a longstanding issue in the industry, Cash says, where most projects take a ventilation approach: They bring in a large amount of outdoor air to ventilate a space. “That approach works fairly well, but it overshoots that target more than 90% of the time. Building systems basically over-ventilate. There are conditions when all of that air is needed if you do not address the contaminant at the source. And that is what makes IAQP so effective; by capturing the contaminant sources in the breathing zone instead of waiting for outdoor air to dilute, you can find a much better balance—just the right amount of conditioned outdoor air along with effective air cleaning when the occupant conditions demand it.”

Stoner says the new smartIAQ product allows a designer to use the latest ASHRAE standards and take a performance-based approach in control of contaminants—whether it’s too many people in a space, an environmental contaminant, or general building-generated off-gassing. “You’re addressing it at the source and you’re not having to increase the size of the equipment on the roof compared to traditional HVAC system design.”

IAQ in Design

Indoor air quality is top of mind in most designs these days, and that’s true of projects by HDR, too. HDR is a global professional services firm specializing in architecture, engineering, environmental, and construction services.

“I think a lot about the VOCs and the products we’re selecting and how that contributes to the quality of space,” says Danielle Masucci, HDR’s workplace design director. “In general there’s a greater awareness of it. We talk about it a lot more with our clients because they’re aware of that sensitivity and the quality of the air in the space.”

How a design addresses indoor air quality makes a big difference to the approach of the building overall, Masucci says, adding that the conversation really begins at a conceptual level.

“Making commitments to how you’re going to ventilate and condition the interior environment and how that can elevate the air quality is really important because the method you move forward with as you design that new building impacts so many things,” she says. “It impacts the floor height; it impacts the roof construction, it impacts the equipment selections and whether you have air handlers or pumps. How do you design to support those building selections, which ultimately impact the energy efficiency in the building?”

Evolving Methods

Classroom design can be greatly improved with smarter IAQ solutions. Photo courtesy of NEC Corporation of America

Cash came into the IAQ game after years in the construction industry working with lighting and controls. He likens what’s happening in IAQ today to conversations about lighting 20 years ago.

“If you think about automated lighting, daylight harvesting, occupancy sensing, all those things really came to the forefront in lighting 20 years ago,” he says. “And then LEDs made them so much easier and more cost-effective. I see that opportunity emerging here.”

Stoner, who’s been in the industry for 30 years (including in mechanical and electrical systems design), says thinking about lighting is a great way to get introduced to energy efficiency and controls and consider the possibilities. “What we’re seeing with indoor air now is that it’s the next energy efficiency opportunity.”

Cash says the change that’s happening now is dramatic. “The single largest energy user in your building is your HVAC system. Think about how you manage the load through variable speed systems to be more responsive to what the space needs versus relying on large amounts of outdoor air,” he says. “I watched lighting go from two-by-four light fixtures consuming more than 100 watts of energy reduced to 18 watts today with the same amount of light—arguably better quality of light—and certainly lower maintenance. The energy savings is massive. The customer experience to not have to change lightbulbs ever again is also astounding. HVAC is next.”

In IAQ, while they can’t eradicate air filters altogether, they can extend the time between changing filters as well as reduce the HVAC watts per square foot on a project by as much as 15 to 30%, since ventilation is such a big part of the conditioning load. “You now have a much more efficient building per square foot, and then by being on demand we don’t exhaust filters very quickly. We get one- to two-year filter cycles, so you get a much lower maintenance proposition than you would normally expect out of an air cleaner,” Cash says.

He says LEED version 5, which is expected to go into effect in 2025, is even taking note, as it accepts the indoor air quality procedure and provides extra points for sensing and response. “You can see this shift occurring. That’s a huge deal to us.”

Cleaner Air, Longer

And while existing buildings lose their performance over time, installing an air cleaner and having variable airflow allows the building to adapt and the system to adequately clean the air in the space. “It is a much more sustainable approach, and that air quality is as good on day 1,000 as day 1,” Cash says.

He says the problem with traditional ventilation is that the issue is never fully resolved. “You need to handle the source. The source for most of the contaminants in a building are either the furnishings or the people. Targeting the source of the problem by cleaning either the source itself, the VOCs in the air, or the formaldehyde that gets emitted from the furnishings—by taking that out of the air, you get better indoor air.” And that, he says, leads to healthier buildings.

“ASHRAE designed the standard around occupant comfort along the lines of air quality and what it means to have clean air. You target the problem at the source, treat it, and deliver better, cleaner, healthier air.”