Story at a glance:

- Sustainable development calls for concerted efforts toward building an inclusive, sustainable, and resilient future.

- Utilizing environmentally friendly building materials can lower the carbon emission impact of construction.

- EPDs are designed meet global market demand for transparent information about product environmental performance.

When we think about sustainability, the three pillars of economy, society, and the environment come to mind. These same principles can be applied to the construction of buildings. Sustainable development has been defined as development that meets the needs of the present without compromising the ability of future generations to meet their own needs. As such, sustainable development calls for concerted efforts toward building an inclusive, sustainable, and resilient future for people and the planet.

There are several ways to achieve sustainable development in the built environment, including consideration for building material and compliance to green codes and standards.

Environmentally Friendly Building Materials

ICC-ES has been evaluating the structural performance of adhesives in accordance with ICC-ES AC05, an Acceptance Criteria for sandwich panel adhesives, ASTM Standard Test Methods (such as ASTM D2559 and ASTM D7247), and ANSI 405 for engineered wood products, CLT, and Glulam. Photo courtesy of Getty Images

Using green materials in building design can help reduce carbon footprint as well as improve health and wellness. Green building materials, also commonly called eco-friendly materials, have a low impact on the environment and are composed of renewable resources.

Mass Timber

Made of renewable building material, mass timber has high strength ratings like concrete and steel but is significantly lighter in weight. Mass timber incorporates the natural aesthetic of wood, with added performance capability.

Products in the mass timber family include but are not limited to cross-laminated timber (CLT), nail-laminated timber (NLT), dowel-laminated timber (DLT), glue-laminated timber (glulam), structural composite lumber (SCL), and solid, built-up, panelized, or engineered wood products that meet minimum cross-section dimensions of Type IV construction. Mass timber can be used in a variety of applications and is the foundation of tall wood building systems.

According to the Tall Wood Institute, 80% of the embodied carbon attributed from building materials comes from structural materials, making it increasingly beneficial to select the most sustainable options. Shifting from concrete and steel construction to mass timber reduces the overall emissions of individual buildings as well as the emissions of the real estate industry as a whole.

Cross Laminated Timber (CLT)

Composed of a renewable resource (wood) and not requiring the burning of fossil fuels during its production, CLT is a sustainable and eco-friendly building material option. CLT consists of layered lumber boards, or laminations, stacked crosswise at 90-degree angles and glued into place. Alternating laminations improve CLT panels’ dimensional stability. Like other mass timber products, CLT can be used in hybrid applications with material like concrete and steel, or used as a prefabricated building component, accelerating construction timelines. Using mass timber also reduces noise and disruption to the building’s surroundings during construction.

Low VOC Adhesive

Wood elements are bonded with approved structural adhesives, but not all adhesives are made equally when it comes to emission readings.

VOC, or volatile organic compound, is the necessary substance used to manufacture adhesives, making them fluid and workable. Once an adhesive is applied, it cures or hardens by the evaporation of the VOC, releasing odorous substances into the air. One of the most common VOCs is formaldehyde—an organic compound that occurs naturally in everything around us, even our own bodies. However, when fabricated into the chemical compound used in synthetic materials like glues, sealants, paint, coatings, and plastics, it can become highly toxic.

The safety of both structures and emissions matter to consumers. In December 2016 the EPA issued the Formaldehyde Emission Standards for Composite Wood Products, based on the California Air Resources Board’s recommendation. This would reduce exposure to formaldehyde emissions from certain wood products produced domestically or imported into the US. The final rule established a third-party certification program for laboratory testing and oversight of formaldehyde emissions from manufactured and/or imported composite wood products. Utilizing low VOC adhesive may help reduce the overall levels of air pollution both indoors and outdoors.

Green Codes and Standards

The International Green Construction Code is the first model code to include sustainability measures encompassing an entire project and its site. Photo courtesy of ICC-ES

Building codes address the important concerns of public health and safety as well as environmental protection. Building codes affect us every day; some requirements, like fire safety codes and structural and seismic standards, affect us in obvious ways. Others, like lighting quality, acoustics, and the air we breathe, also have major effects on our health and productivity.

The International Code Council (ICC) was founded in 1994 by the three regionally based model code organizations. The purpose was to streamline the building regulatory system through a single family of codes, offering consistency and compatibility to multiple layers of requirements existing at the federal, state, and local level. The Code Council updates editions every three years and comprise of a set of integrated, topical model codes, including the International Building Code, the International Residential Code, and the International Plumbing Code, among others.

ICC also publishes the International Green Construction Code (IgCC), developed in partnership with the AIA, ASTM, ASHRAE, USGBC, and IES. A whole systems approach to the design, construction, and operation of buildings, the IgCC contains measures that result in better indoor environments, lower impact on natural resources, better neighborhood connections, and improved walkability. The IgCC provisions allow the seamless coordination with either the IECC or ASHRAE Standard 90.1 for ease of adoption in any jurisdiction.

Independent Product Evaluation

ICC-ES reports provide information about what code requirements or acceptance criteria were used to evaluate a product, and how the product should be identified, installed, and more. Photo courtesy of Getty Images

Product evaluation is a review of products against a standard, code, or criteria to ensure continuous compliance of products. Certification steps include review of products, periodic inspection of plants, and periodic review of submitted information against new or revised standards.

ICC Evaluation Service (ICC-ES) provides rigorous technical evaluation to provide manufacturers proof of code compliance to green codes and standards like the IgCC, CALGreen, LEED, and others. Throughout the life of an evaluation report, surveillance inspections are periodically conducted to ensure no unauthorized changes have occurred in the manufacturing process, and that the product has not varied from what was originally certified.

There are circumstances when for an innovative product, like low-formaldehyde adhesive, is not yet recognized in the code or by a standard. In this case Acceptance Criteria are developed, creating a level playing field for evaluation.

ICC-ES has a comprehensive product evaluation service available for tall wood building products, including CLT panels used in diaphragm and shear wall design, for products needing approval for the North American market. For example, ICC-ES AC455 for Cross-laminated Timber Panels for Use as Components in Walls, Floors and Roofs has recently been updated to the 2021 International Building Code and International Residential Code.

Updates reflect:

CLT diaphragm design in accordance with the 2021 American Wood Council (AWC) Special Design Provisions for Wind and Seismic (SDPWS)

CLT shear wall design in accordance with 2021 AWC SDPWS or ICC-ES AC494 utilizing FEMA P695 analysis

Fire resistance rating for connections constructed using CLT panels and other mass timber elements in Type IV-A, IV-B, and IV-C construction in accordance with 2021 IBC Section 2304.10.1

In cooperation with APA – The Engineered Wood Association, ICC-ES also offers a joint evaluation program for wood products, including wood structural panels, siding, structural composite lumber, prefabricated wood I-joists, and CLT.

The ICC-ES Sustainable Attributes Verification and Evaluation Environmental Program provides manufacturers with independent and comprehensive evaluation and certification that their products meet specific sustainability targets. These services are offered under the ICC-ES Verification of Attributes Report (VAR) and Environmental Product Declaration (EPD) programs.

Many manufacturers already have evaluation reports to address eco-friendly building materials, like Weyerhaeuser VAR 1008 for structural wood products—lumber, floor panels, sheathing, and plywood. A full directory of ICC-ES VAR reports may be found here.

New Requirements for Environmental Product Declarations

AC529 was developed by ICC-ES engineers and interested parties to show building code compliance and applies to low-carbon alternative cements that are activated by water or a proprietary activator supplied by the manufacturer. Photo courtesy of Getty Images

EPDs are designed to meet the global market demand for science-based, transparent, quality-assured information about product environmental performance. An EPD is a third-party verified summary of the primary environmental impacts—including greenhouse gas emissions—from a product’s extraction, transportation, and manufacturing.

On March 17, 2022, the US General Services Administration (GSA) released requirements for EPDs and emissions targets for concrete and asphalt for GSA buildings. These standards are the first in the US to apply beyond a local jurisdiction and will help strengthen American leadership in clean manufacturing and propel clean energy innovation.

The new low embodied carbon concrete standard requires GSA project contractors to provide EPDs, where available. Type III Program Operators like ICC-ES are qualified to verify and publish EPDs that provide exactly this type of summary.

Developing an EPD

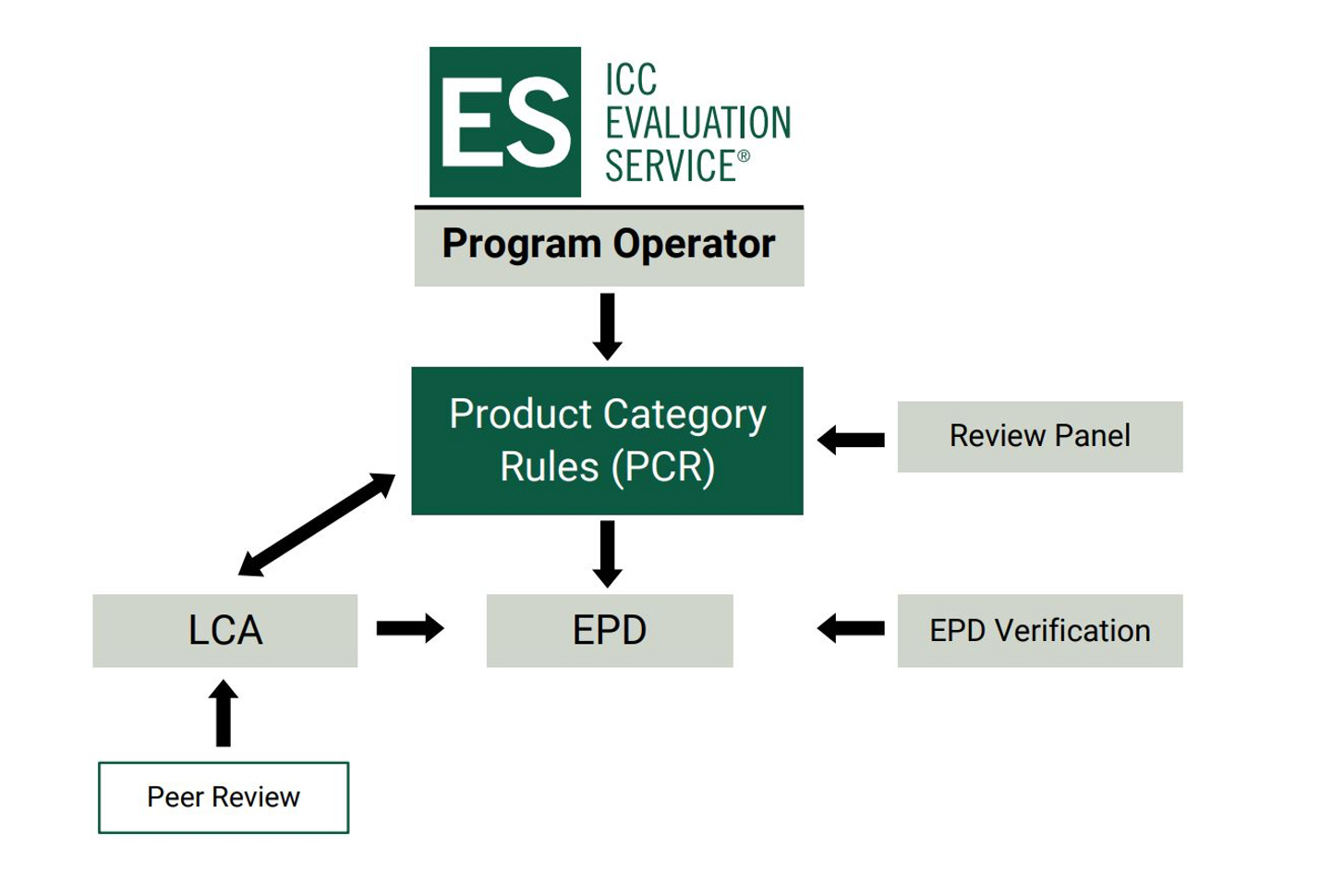

The EPD process results in a transparent declaration of a product’s environmental effects. Chart courtesy of ICC-ES

Based on Life Cycle Assessment (LCA), EPDs are rapidly becoming a key component of the material selection process, particularly in the building sector. ICC-ES helps to meet industry demand by serving as a Type III Program Operator with published Program Instructions.

“As a Type III Program Operator, ICC-ES provides manufacturers an opportunity to establish third-party verification of their commitment to environmentally conscious building products through the EPD program,” says Eric Polzin, ICC-ES environmental program manager.

LCA reports detail the environmental impacts of a product across its life stages—material extraction, production, transportation, installation, use, and end of life. LCA reports can be lengthy and difficult to navigate, which is why this information is typically summarized in a shorter-length EPD. The EPD is a compact summary of an LCA report with additional information about the product useful for comparisons with similar products.

The EPD declares impact measures such as:

Greenhouse gases

Ozone depletion

Acidification of land and water sources

Eutrophication (the process by which a body of water acquires a high concentration of nutrients, especially phosphates and nitrates, that typically promote excessive growth of algae)

Formation of smog

The EPD also discloses uses of resources and renewable energy, as well as whether waste is declared as a hazardous material.

Product Category Rules (PCRs) define the product category and provide a detailed set of procedures for the LCA. Accredited Program Operators are responsible for developing the PCR using a defined process that includes but is not limited to consultation with identified stakeholders with expertise in LCAs as well as those knowledgeable about the product and its manufacture.

The PCR is registered under the Program Operator that supervised the development and/or revision of the PCR and subsequently conducted a panel review in accordance with the ISO standards.

Once the PCR has been finalized, an LCA must be completed or modified as necessary to comply with the PCR. As defined in the ISO standards, an LCA is a “compilation and evaluation of the inputs, outputs, and the potential environmental impacts of a product system throughout its life cycle.” While it is only mandatory to verify LCAs for use in B-to-C EPDs, a PCR may require a peer-reviewed LCA for a B-to-B EPD.

The EPD may be created by the manufacturer or the manufacturer’s representative, or by a third party. The EPD document encapsulates the essence of the LCA, providing the user with all of the basic information and results necessary for a fully transparent declaration of environmental effects.

The Program Operator is responsible for confirming that the EPD complies with the applicable international standards and the PCR. EPD verification may be conducted by an internal reviewer for B-to-B declarations and by a third-party verifier for B-to-C declarations. The Program Operator appoints the verifier and establishes a transparent verification procedure, usually in consultation with the verifier.

The manufacturer also has the option to include within the EPD an independent evaluation of their product to other normative reference documents like the model building codes and/or green building rating systems within the EPD.

Summary

Independent building product evaluation addresses solutions to environmental impact challenges. Photo courtesy of Getty Images

Providing proof of code compliance for concrete and asphalt applications is now mandated in some jurisdictions, and the requirement is expected to expand to other product categories. There is no need to wait until a requirement has been issued to certify a product.

Product certifications (issued as evaluation reports) provide numerous benefits:

If you are a building regulator, evaluation reports can tell you about products, systems, materials, and methods that are code compliant.

If you are a manufacturer, an evaluation report will make it easier to market your building-related product, because you have solid evidence that your product meets code requirements.

If you are a specifier, designer, architect, or contractor and you want evidence for the local building official that you are using sustainable, code-complying materials, an evaluation report will provide this.

If you are a member of the public, you benefit from product certification because code compliance promotes public safety in the built environment.

Whether the goal is to address the economy, society, or the environment, building product certification provides security and peace of mind. Third-party verification provides the solution to safer, more sustainable building products and systems.

Evaluation reports for mass timber/tall wood building products can be obtained through the ICC-ES Evaluation Reports Program.