Story at a glance:

- Experts point to cold-formed steel as an excellent choice for sustainability.

- AEC professionals benefit from increased versatility and flexibility in their designs.

The last couple of years have seen robust growth in the market for cold-formed steel. A combination of trends in the construction industry—from labor shortages to a greater emphasis on sustainable materials and improved workplace safety—has increased demand for cold-formed steel framing systems.

“Cold-formed steel is transforming modern construction by offering a versatile, sustainable, and high-performance alternative to traditional building materials,” says Steve McDaniel, vice president of business development at Marino\WARE, a leading manufacturer of steel framing products.

The overall benefits of cold-formed steel framing systems are well known in the building industry, yet many professionals may not be aware of the technological advancements that manufacturers of cold-formed steel have invested in to improve its performance.

“We’ve gone out of our way in the industry to adapt and modernize to address the pain points we’re hearing from customers,” says Jim DesLaurier, vice president of engineering and technical resources at Marino\WARE. “Our research and development has focused on streamlining installation and addressing issues like sound quality and safety on the jobsite.”

These innovations have made cold-formed steel lighter, stronger, more sustainable, and easier to work with. At the same time Marino\WARE and other cold-formed steel manufacturers have made advancements in products focused on acoustical control and fire safety.

“AEC professionals benefit from its superior strength, efficiency, and adaptability, making it an ideal choice for diverse applications across commercial, residential, and industrial projects,” McDaniel says.

Versatile Applications

Photo courtesy of Marino\WARE

Cold-formed steel can be used in nearly any type of project for interior framing, partitions, curtain wall construction, roof trusses, and floor systems.

“It combines the versatility of wood construction with the strength and reliability that concrete gives you,” says Eric Zuidema, senior structural engineer with global design and construction firm Stantec. “It’s a good mix between the two, so I think that really is the highlight of cold-formed steel.”

The most popular use cases for cold-formed steel studs are typically for the framing of mid-rise projects like multi-family residential and hotels, as well as modular construction. Cold-formed steel can generally be used to construct buildings up to around 10 stories without the need for other structural materials.

Though elevated interest rates and the continued popularity of remote work have dampened demand for new office space, other areas of the construction industry are seeing robust demand for cold-formed steel framing. Data centers have been a true bright spot, as the rapid adoption of AI has set off a frenzy of activity in this sector.

“We are observing a dramatic rise in data center construction, a sector where cold-formed steel excels,” McDaniel says. “Cut-to-length cold-formed steel framing offers unparalleled efficiency in these projects, enabling rapid installation and ensuring compliance with stringent deflection and non-combustible material specifications.”

Sustainable Manufacturing

Photo courtesy of Marino\WARE

Despite federal policy uncertainty, the demand for sustainable building products has continued to grow at an impressive clip, which has boosted the market for cold-formed steel framing in particular.

Most cold-formed steel products used today have a high recycled content, and the material can be recycled indefinitely—making it one of the most sustainable construction materials on the market, and one that can contribute to green building certifications.

The manufacturing process for cold-formed steel is also highly efficient. One of the most popular methods, electric arc furnace steelmaking, involves using high-current electric arcs to melt recycled scrap steel, which is then processed through rollers. This method emits significantly less GHG emissions than the blast furnace-basic oxygen furnace steelmaking process. “You get high recycled contents, excellent embodied carbon numbers, and you do so without having to clear-cut forests as you would for wood studs,” DesLaurier says.

Marino\WARE’s steel products also feature a choice of Product-Specific Type III Environmental Product Declarations (EPDs) that provide project teams with detailed, transparent data on the environmental impact of its products.

One applies to all of the company’s cold-formed steel framing products, regardless of production method. The other is a low embodied carbon EPD that specifically details the environmental advantages of cold-formed steel products manufactured with the electric arc furnace method, allowing customers to make informed decisions on embodied carbon metrics.

“These efforts empower our customers and partners with the information they need to make environmentally responsible choices while reinforcing our dedication to reducing the industry’s carbon footprint,” McDaniel says.

Exceptional Durability

Photo courtesy of Marino\WARE

Compared to its main competitors, cold-formed steel is resistant to corrosion, mold, and fire, and impervious to termites and other pests, which all contribute to the long-term structural integrity of a project.

Cold-formed steel studs don’t warp, shrink, or crack like traditional wood studs. And with such a high strength-to-mass ratio, the material provides a higher level of structural strength while remaining lightweight and easy to work with. “This allows for more efficient material usage, smaller foundations, and lower transportation costs,” McDaniel says.

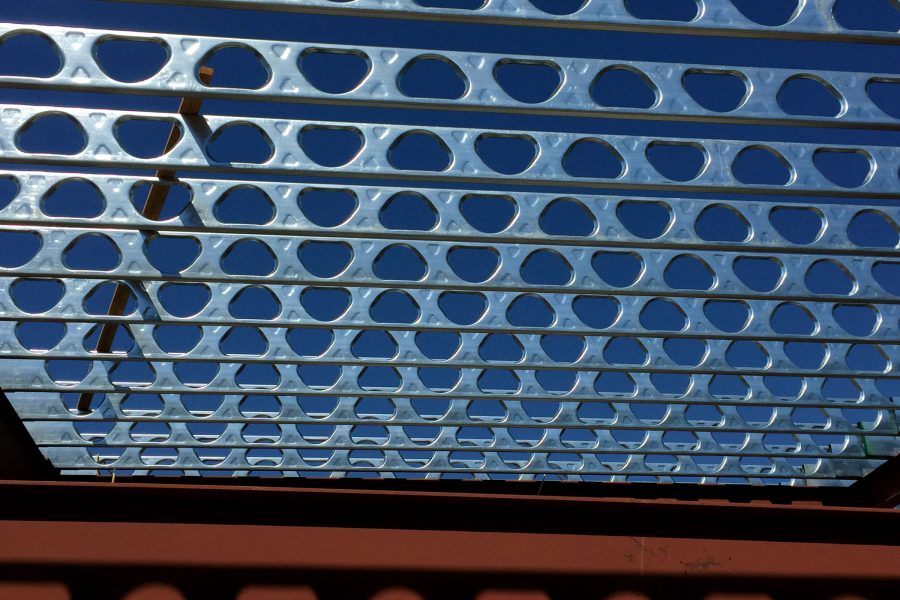

For example, Marino\WARE’s StudRite open-web stud system has one of the best strength-to-mass ratios of any stud available on the market. Though they are far lighter than traditional studs, the lip reinforced repetitive triangular cutouts and embossments help it achieve maximum structural integrity.

This superior performance makes it an excellent choice for projects in seismic zones or high-wind environments that require additional resilience and safety. “These features are especially important for multi-family residential buildings, hospitals, hotels, and other high-risk environments,” McDaniel says.

And with a growing focus on durability, the steel framing industry has made advancements in firestopping devices that, unlike traditional caulk, have no curing time, do not crack over the life of the structure, and minimize the need for maintenance every few years.

“The beauty of the next generation of pre-formed firestopping devices is that you don’t have to worry about any of that,” DesLaurier says. “Their efficacy is long-term versus having to go back and pull out the ceiling tiles or the wallboard to treat those.” Marino\WARE’s HOTROD XL surface-mounted fire deflection device addresses these pain points by slotting directly between wall and ceiling joints, combining a flat deflection bead with compressible foam and intumescent tape for a full seal that provides one- and two-hour firestopping solutions.

Improved Acoustics

- Photo courtesy of Marino\WARE

- Photo courtesy of Marino\WARE

In recent years developers and design professionals have placed a greater emphasis on improving the acoustics of a space and exploring how framing materials can positively or negatively impact sound quality. Marino\WARE has responded to this shift in the market by focusing some of its research and innovation efforts with SoundGuard, a proprietary acoustically decoupled steel stud system. “A wood stud is stiff so it transmits more sound, whereas a steel stud is much better when it comes to sound transmission,” DesLaurier says.

SoundGuard was chosen as the primary framing material for a recent courtroom project where stringent sound control was critical for privacy. The design features architectural reveals that present a common challenge in achieving optimal acoustical performance.

Marino/WARE addressed this challenge by providing detailed technical data demonstrating that the SoundGuard system could achieve high sound transmission control ratings even with the reveals, ensuring courtroom confidentiality. “SoundGuard was designed to overcome these challenges, offering a streamlined and highly effective acoustic solution that enhances performance while optimizing cost and installation efficiency,” DesLaurier says.

Cost-Effective, Safe Installation

With labor shortages and rising material costs affecting the industry, firms everywhere are looking for innovative ways to cut down on time and resources for onsite construction. Developers and contractors have turned to modular construction and offsite prefabrication to address these issues, and steel framing systems—which are lighter and more flexible than wood—remain the ideal material for these practices.

“Costs are absolutely a driver in the industry,” Zuidema says. “On one of our projects we had an entire load-bearing cold-formed steel wall premanufactured and brought onsite to cut down on construction time,” versus stick-building the stud frame one at a time.

Most of Marino\WARE’s cold-formed steel orders are cut to specification, which significantly reduces wasted materials onsite. “This minimizes labor costs by eliminating or reducing onsite cutting, and streamlines installation, ultimately leading to overall project savings,” McDaniel says.

And the fact that cold-formed steel studs have gotten lighter means that instead of needing two workers to lift a tall stud into place, that process now only requires one, further cutting down on labor.

The lightweight quality of cold-formed steel also addresses safety issues on jobsites, since workers are less likely to strain themselves or drop the material, potentially harming themselves and others.