Story at a glance:

- Fiberon offers a long-lasting, low maintenance alternative to traditional wood.

- Every year Fiberon saves more than one million trees from being cut down.

- Fiberon’s product is made from at least 94% recycled content.

The idea for Fiberon’s revolutionary new Wildwood composite cladding sprang from a product the company had been manufacturing with great success for two decades: composite decking. Customers began telling them that it also worked extremely well on walls—even though it wasn’t made for that purpose.

And so an intensive, five-year R&D process began that eventually produced the lighter, thinner, and more facade-friendly Wildwood line. Officially launched in 2021, it is what all exterior cladding should be and more: aesthetically versatile, long-lasting, low-maintenance, highly sustainable, and backed by certifications from years of testing.

What are Wood Plastic Composites?

The Eden Collection is inspired by lush, tropical forests and features an array of exotic hues including Wenge, Meranti, Tupelo, Mora, and Koa. Photo courtesy of Fiberon

Wood plastic composites (WPCs) are a roughly 50/50 blend of small wood particles (i.e. wood flour) and thermoplastic polymers. They have all the best qualities of wood (high strength, low cost) plus the resilience of recycled plastic—which is less prone to water absorption and insect infestation and means their longevity is unmatched.

Unlike solid wood, WPC won’t crack, splinter, or warp. It also requires less maintenance. Keep in mind, though, that while composites are great at preventing water penetration, they aren’t impervious to it due to the wood component.

Specifying high-quality composite boards (like Wildwood) that are capped on at least three sides helps to further slow this process. Many common cladding materials will absorb water quite readily rather than deflect it. Rainscreen systems are one of the most effective methods for managing moisture (more specifically bulk infiltration, capillary intrusion, and vapor exfiltration) and mitigating damage to residential and commercial structures.

Additionally, wood plastic composites provide greater design flexibility than solid wood. Not only can they be manufactured in many shapes, colors, and textures, but a variety of wood species—including pine, maples, and oak, depending on regional availability—can be incorporated into the finished product.

Beautifully Functional

The Eden Collection in Koa. Photo courtesy of Fiberon

Some products sacrifice looks for longevity. Not Wildwood, which has both in equal measure at an extremely competitive price point. Its two nature-inspired color collections—Eden (inspired by lush, tropical rainforests and available in an array of exotic hues) and Sahara (reflective of arid, sandy landscapes, it comes in several rich desert tones like Bamboo and light-blonde oak) —feature realistic embossing patterns and come in a wide variety of board lengths that result in fewer seams and a much cleaner aesthetic. And they’re purposely complementary in appearance, so they can easily be mixed and matched.

“We’ve done a lot of building entrances,” says Jim Stange, Fiberon’s longtime senior product manager. “Wildwood gives them a lot more warmth, especially when the facades are made of stone. It softens the tone of a building’s exterior.”

Thanks to laser and visualization technology that produces consistently high-quality and aesthetically superior cladding, Fiberon composite cladding better emulates natural wood compared to alternative materials like fiber cement. Products with low-gloss formulas and micro-texturing have a matte finish, which further enhances their natural look.

Recently, a handful of developers of upscale custom homes have begun using Wildwood cladding on their model homes and offering it to prospective buyers as an upgrade, Stange says. It’s also popular among private equity firms purchasing rundown buildings, revitalizing them with Wildwood cladding and flipping them for a profit.

“We’re learning that our product not only has a unique look that they like, but it gives their properties increased equity right off the bat because of the material’s longevity. They can sell that building with a 50-year warranty on the cladding.”

Install It and Forget It

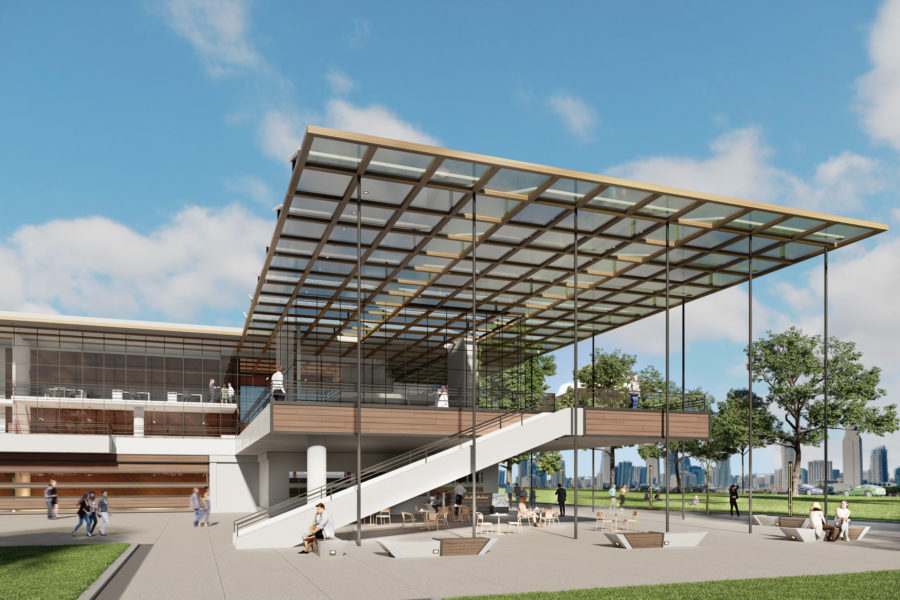

Fiberon Wildwood is seen here in Sumac. It includes the exclusive PermaTech cap layer to protect against staining and fading. Rendering courtesy of Fiberon

“Commercial buildings are held to a different standard than residential ones in that building owners are particularly interested in maintenance cycles and the longevity of products that go into their facades,” Stange says. “With a composite cladding system like Wildwood we’ve eliminated nearly all maintenance.”

That’s because Wildwood features a PermaTech cap layer that protects against fading and staining. And thanks to a durable composite core, it’s nearly impervious to moisture retention, insect infestation, cracking, and decay. Architects are especially impressed with its resistance to paint adhesion, which allows for easy cleaning if the surface is vandalized. It’s also approved for high-velocity zones, and it adheres to the strict NFPA 268 code standard for flame and heat resistance.

The advantages of those qualities can’t be overstated, particularly for service-oriented buildings like hospitals and restaurants. Real wood looks great at first, but it soon requires sanding, pressure-washing, and regular inspection to replace any rotting boards. In other words, it’s pretty constant upkeep. And the expense of that upkeep isn’t limited to the upkeep itself. Maintenance on multi-use properties means downtime, which also costs owners money. Wildwood lets them focus on their core business rather than the structure that houses it.

Unparalleled Sustainability

The Eden Collection in Tupelo. Longer lengths result in fewer seams, creating a cleaner aesthetic. Photo courtesy of Fiberon

Wildwood is at least 94% recycled content, as verified by an independent accredited service. That’s no surprise, seeing as sustainability has been a core Fiberon value for decades. They’re so serious about it that they have their own in-house recycling program at a facility near Charlotte, North Carolina. Equipped with three high-tech machines that sort through and repurpose pallet loads of recyclables, it’s part of Fiberon’s commitment to life cycle analysis—understanding every stage of a product’s value chain, from cradle to grave.

At significant cost, the entire process is meticulously documented—everything from where the material originates to how much energy it takes to produce cladding. It’s all part of Fiberon’s Environmental Product Declaration (EPD), and architects often look for EPDs when choosing materials for their buildings. A third-party evaluation of Wildwood is currently underway and will soon be publicly available.