Story at a glance:

- Staining masonry and concrete addresses many of the design and maintenance flaws of traditional paints.

- Stains chemically bind to the substrate they are applied to, increasing its lifespan.

- Nawkaw is a leading manufacturer and installer of architectural finishes, including concrete stains.

Concrete is the most common building material on earth. It’s durable, versatile, and affordable, yet few architects or designers would say it’s at the top of their list of visually appealing materials to work with. While some solutions make it more aesthetically pleasing, painting concrete can lead to its deterioration when moisture gets trapped under the coating. As a result, concrete and masonry stains are rising in popularity, as they form penetrative mechanical bonds, chemical bonds, or both with the substrate they are applied to, increasing durability and lifespan.

“Architects and designers are always keen to look toward the full life cycle of their designs,” says Kasia Purzycka, president of Nawkaw, a leading manufacturer and installer of architectural finishes, including concrete stains. “They’re considering upkeep costs and carbon emissions throughout the first five, 10, 15 years of a building’s maintenance and operations.”

Design Potential

Perkins Eastman used concrete stains on a new residence hall at Frostburg State University in Maryland to get the dark black they wanted on the exterior precast concrete of the building. Photo by Andrew Rugge, courtesy of Perkins Eastman

The versatility of stains opens up nearly limitless design opportunities. “Concrete staining really allows you to leverage the materials that are already there and allows you to get more of an elevated finish on a base product,” says Charles Kimmel, architect at Perkins Eastman.

For architects and project teams looking to craft unique designs with masonry and concrete, stains offer a far broader range of opportunity than traditional paint solutions and allow designers to bring new life to these traditional materials.

“Stains give you a range in the color palette that you can’t get with paint pigments, where you can get into the darker colors and match the masonry with the style of the architecture,” Kimmel says.

Possible Solutions

Metallic finish work by Nawkaw. Photo courtesy of Nawkaw

Nawkaw’s suite of stain solutions include translucent finishes, metallic and glossy finishes, and pearlescent looks. Their technicians have applied their products onto form-lined concrete surfaces to replicate the look of wood, stonework, metal paneling, leather, and cork, among other natural textures.

The exact details of their process are a proprietary secret, but how Nawkaw’s technicians can so closely replicate natural materials is all about the application. Replicating the look of wood on concrete, for example, involves applying a base coat and then using a sponge to add accents that mimic the look of wood grain.

“Limitations on what you can do with stains often fall to the imagination of the designer or architect,” Purzycka says.

Improved Looks

The versatility of stains allows designers to be far more adventurous with concrete and masonry structures than before. Perkins Eastman, for example, turned to concrete stains for the design of a new residence hall at Frostburg State University in Maryland.

“To get the dark black that we wanted on the exterior precast concrete of the building, stain was the only way to get there,” Kimmel says.

The bold design of the six-story, 125,000-square-foot residence hall put the finishing touches on a previously underused residential quad on campus.

Trends in the Market

In terms of aesthetic appeal and color, experts point to a high demand currently for clean, modern finishes.

“Monochromatic looks are highly popular,” Purzycka says. “As we move deeper into the decade, the white and black look is slowly giving way to new and beautiful shades of natural greens, warm neutrals, and blues.”

The white and black look is slowly giving way to new and beautiful shades of natural greens, warm neutrals, and blues.

The trend of replicating various materials using color and formlined concrete is growing and shows little signs of abating. This approach increases durability and reduces costs as well as the delays often associated with sourcing materials like metal paneling or natural wood.

“Those looks and more traditional looks such as brick and mortar can each be replicated utilizing high-quality stains paired with textured or even smooth concrete surfaces,” Purzycka says.

With elevated material and labor costs and some supply chain issues never fully recovered from the pandemic, many customers are searching for a high-performance color solution they won’t need to worry about in the decades to come.

Sustainability

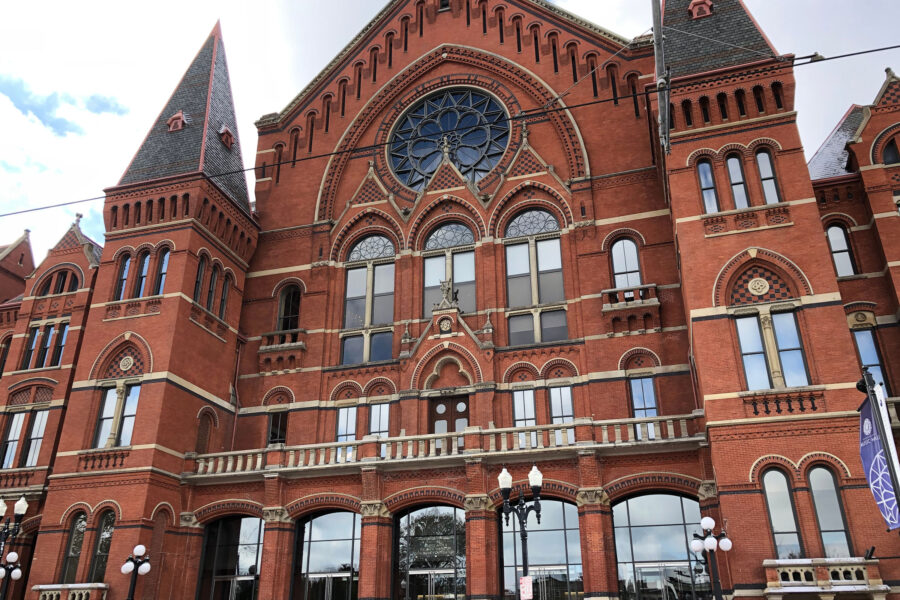

Nawkaw’s work on the Cincinnati Music Hall project included blending the color of mismatched bricks and mortar work to return the facade to its former glory. Photo courtesy of Nawkaw

Many others also demand their products be sustainable.

“It’s a real cultural shift and sea change we’re seeing from younger generations, and rightfully so,” Purzycka says. “It is a moral imperative we all need to strive for.”

All sectors of the building industry have seen a major shift recently toward historical preservation work and existing building retrofits, driven in part by federal, state, and local incentives that aim to combat greenhouse gas emissions from the built environment. “Oftentimes the most sustainable building is the one that is already built,” Purzycka says.

Concrete and masonry stains are regularly used to support projects that restore legacy buildings to their original design and colors. “In smaller communities especially, this work is preserving iconic elements of a town’s culture for future generations.”

This work extends to historical landmarks in major cities as well. Built in 1878, the Cincinnati Music Hall had well over a century of exposure to the elements when its owners embarked on a major renovation that included extensive improvements to the building’s interior and exterior.

Years of tuckpointing, wall replacement, and infill work on the music hall’s facade left the brick exterior uneven and visually disjointed. Nawkaw’s team used the firm’s color-matching stain solutions to create a cohesive look across the facade while masking repair and infill work.

“We were able to blend the color of mismatched bricks and mortar work and return the facade to its former glory,” Purzycka says. “It’s incredibly and deeply rewarding work to return a building this old to its original form.”

While concrete is prolific in the built environment, it is also considered one of the least sustainable materials to create and transport. And given that truly sustainable concrete solutions are still being scaled for mass production, current efforts must also focus on increasing the longevity of existing concrete structures—and stains can add decades to the life of the material.

“I think it’s critical we stay clear-eyed about the impact construction has on our environment. No matter how you look at it, concrete production makes up an outsized amount of annual carbon emissions. We have a fiscal, ethical, and moral imperative to lead the way when it comes to sustainability,” Purzycka says.

Building Performance & Durability

Because of the high durability of concrete and masonry stains, these finishes will last for decades with proper maintenance and can improve the durability and lifespan of the materials they envelop, too. “That’s far simpler, more cost effective, and more sustainable than maintaining even a premium paint coating on a similar substrate,” Purzycka says.

Unlike traditional paints, stains penetrate the substrates they are applied to and form strong mechanical bonds, chemical bonds, or both—serving as a densifier to concrete and masonry, she says. Stains are also more permeable, allowing moisture from rain and snow to evaporate more efficiently than it is absorbed into the facade.

“Why is that good? Because the stain won’t peel; it’s a permanent bond,” Purzycka says. “You won’t experience the problem of facade deterioration.”

Even high-quality paints, including premium acrylic and epoxy-based coatings, can seal off the natural voids and channels in concrete, entrapping moisture, she says. “Good stain products have a permeability of 25 perms. Our products show around 80 perms for a single coat, and we’re happy with that.”

Trapped moisture can also contribute to carbonation of concrete and cut short its lifespan. Similarly, moisture trapped in a brick facade can cause deterioration and spalling of the bricks.