Story at a glance:

- GCP has two proven solutions that meet essential barrier requirements for pre-applied and post-applied applications.

- PREPRUFE 300R Plus is a composite sheet membrane composed of a thick high-density polyethylene (HDPE) film, pressure-sensitive adhesive, and weather-resistant protective coating.

- BITUTHENE 8000 is a self-adhesive, cold-applied sheet membrane for above- and below-ground applications.

With the availability of buildable land declining in many high-demand markets, the pressure to build on suboptimal lots, including brownfields, is intensifying. This makes the requirement to install a robust, continuous waterproofing and gas membrane between the ground and the structure more critical than ever.

Dual Threats: Water and Methane

Water intrusion is a perennial concern due to its impact on the long-term structural integrity of concrete foundations and walls—and of the building itself. Concrete is vulnerable to groundwater and chemical contaminants in the soil. These can leach into the pores and cracks of the concrete and degrade its integrity, causing spalling and corroding the reinforcing steel. Moisture migrating into the building can also degrade structural elements over time and lead to mold and other hazards to occupants’ health.

In addition, there is growing concern regarding the intrusion of methane and other gasses and chemicals, like trichloroethylene and perchloroethylene, from the soil. Methane, a hydrocarbon, is a potent greenhouse gas and can have serious health implications for building occupants. In some jurisdictions this concern is driving regulations requiring proactive mitigation. In the US California is leading the trend with methane mitigation standards issued by the LA Department of Building and Safety. To comply with these standards, any methane barrier must have Los Angeles Research Report approval, certifying that it meets testing requirements defined by the city.

Essential Barrier Requirements

Meeting these challenges demands a pre-applied or post-applied membrane that meets a host of functional and performance requirements. It must be:

Continuous, preventing any gaps that could allow water or gas intrusion

Fully bonded with the concrete, preventing voids that could allow water or gas migration between the barrier and the substrate

Durable, with the ability to stand up to the elements for the life of the structure

Easy to install, ensuring correct application with typical installer skills and equipment

Proven, with a track record of performance under real-world conditions

Backed by a company recognized for technical innovation and product support excellence

GCP has two proven solutions that meet these requirements for both pre-applied and post-applied applications: PREPRUFE® 300R Plus and BITUTHENE® 8000.

Pre-Applied Barrier: PREPRUFE 300R Plus

PREPRUFE 300R Plus is a composite sheet membrane composed of a thick high-density polyethylene (HDPE) film, pressure-sensitive adhesive, and weather-resistant protective coating. As a pre-applied membrane, it is installed directly against the formwork or other soil retaining system before the reinforcement is placed. Concrete is then poured directly onto the membrane, forming a permanent, continuous bond with the PREPRUFE 300R Plus membrane. The membrane’s waterproofing system does not require water activation, confining pressure, or chemical hydration to bond with the concrete.

Once installed on the formwork, the PREPRUFE 300R Plus membrane can be trafficked immediately, allowing placement of reinforcement using standard concrete spacers. The installed membrane is unaffected by typical jobsite conditions, including wet or freeze/thaw conditions.

Post-Applied Barrier: BITUTHENE 8000

BITUTHENE 8000 is a self-adhesive, cold-applied sheet membrane for above- and below-ground applications. It can be used either horizontally or vertically. BITUTHENE 8000 features a thick, HDPE composite carrier film. BITUTHENE technology has been proven in more than 50 years of use in the field across countless projects, under a wide range of conditions.

Performance Advantages of HDPE and HDPE Composites at the Right Thickness

Key to the long-term performance of PREPRUFE 300R Plus and BITUTHENE 8000 is the optimal thickness of their HDPE and HDPE composite carrier film material, respectively. This thermoplastic polymer has distinct performance characteristics that make it ideal for use as a waterproofing and gas barrier membrane.

HDPE is an inert material that resists degradation over time. Some waterproofing membranes are made of materials that have higher levels of degradation due to their polymer structures. These include linear low density polyethylene (LLDPE), PVC (polyvinyl chloride), EPDM (ethylene propylene diene polymer), and CSPE (chlorosulphonated polyethylene). LLPDE, PVC, and EPDM are at particular risk of oxidation, while CSPE suffers from dehydrochlorination. HDPE has greater resistance to oxidation, hydrolysis, and stress than these other materials, making it an ideal choice for use as a geomembrane.

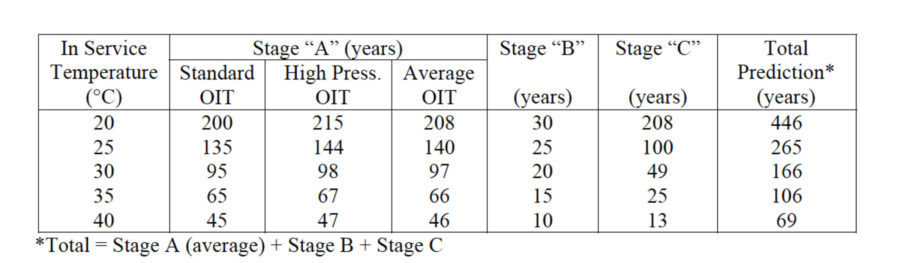

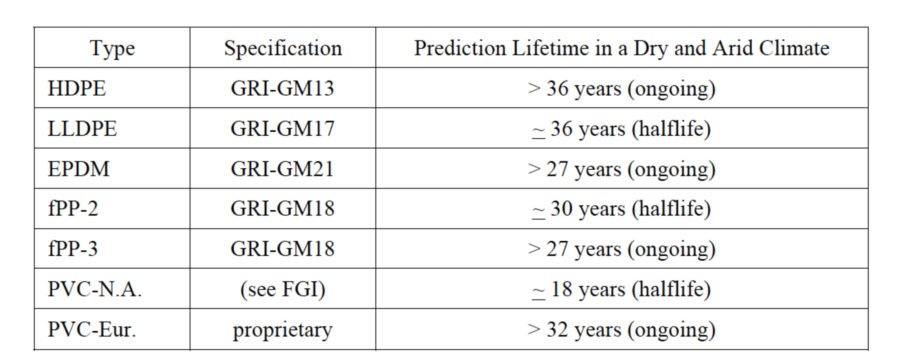

Independent scientific testing has shown that HDPE offers longer life than other commonly used membrane materials in both unexposed and exposed applications (see Figures 1 and 2).

Figure 1: Total lifetime prediction of HDPE (non-exposed) at various field temperatures. Stage “B” is induction time; Stage “C” is the time for 50% change in mechanical properties. Table courtesy of GCP

Exposed lifetime prediction results of selected geomembranes to date (2011). Table courtesy of GCP

Ease of Application

Proper installation is crucial to ensure the long-term performance of a water or gas membrane. Complex or unclear processes increase the chances of installation errors that can lead to leaks. PREPRUFE 300R and BITUTHENE 8000 are thoughtfully designed for ease of installation.

PREPRUFE 300 features a kick-out roll for simple installation against concrete forms. ZipLap selvedge seams allow for an adhesive-to-adhesive bond at membrane sheet overlaps to create a continuous membrane, without the need for heat, power, or specialized equipment. The membrane can be installed to permanent formwork, allowing maximum use of confined sites. Detailing watertight penetrations is easy with BITUTHENE liquid membrane.

BITUTHENE 8000 is easy to apply by simply peeling back the protective release paper and applying to the properly prepared concrete surface. Surfaces (except those below ground-bearing slabs) should be primed with a single coat of the specified primer. Installation can be performed over a wide temperature window—from -5°C to +35°C (a hot climate variant is rated to 55°C)—and is tolerant of damp surface, helping avoid delays. The exposed surface is reflective, reducing solar heat absorption by more than 20% while the membrane is exposed, preventing degradation due to UV rays. Printed lines help ensure the correct overlap (minimum 50mm) and provide a continuous membrane when well rolled using a lap roller with firm pressure. Detailing can be performed using cut sections of BITUTHENE 8000 or BITUTHENE liquid membrane.

Summary

GCP helps building engineers, architects and contractors meet the challenges of today’s construction site realities with advanced solutions for above- and below-grade waterproofing and methane barriers. PREPRUFE 300R Plus and BITUTHENE 8000 offer two compelling solutions for mitigating risk, ensuring regulatory compliance and protecting the health of building occupants—today and into the future.