In today’s AEC industry, there is a growing expectation to think more holistically about the impact of building products used in construction and the fate of materials when they come to the end of their serviceable life.

The World Resources Institute estimates 80% of all materials and minerals in circulation in the American economy are consumed by the construction industry.

Photo courtesy of StructureCraft

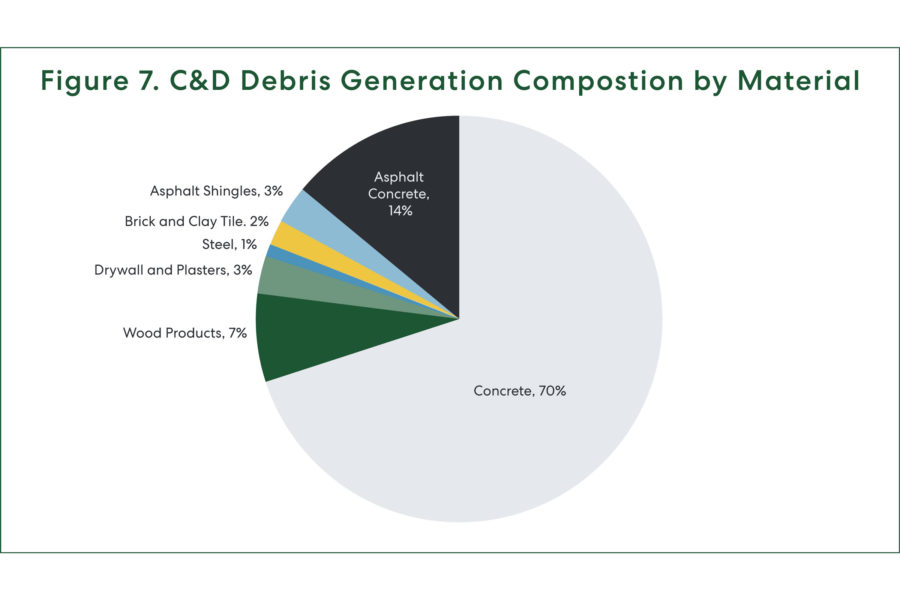

The built environment is the world’s largest consumer of raw materials by sector and produces significant construction and demolition (C&D) waste. In 2018 alone the US generated 600 million tons of C&D debris—more than twice the amount of municipal solid waste picked up from homes and businesses.

Construction and Demolition Debris Generation in the United States, 2014 EPA. Image courtesy of Think Wood

Shifting to a Circular, Regenerative Model of Construction

As the data reveals, building materials have historically followed a “take, make, dispose” linear model of consumption, where resources are extracted for product manufacture and products are disposed of at the end of their life.

But with building materials accounting for 39% of global GHG emissions, there is a growing imperative for AEC professionals to consider product end-of-life in their specification decisions. This includes a shift to a circular economy and choosing building materials that are naturally renewable, and/or can be reused or remanufactured at the end of their use.

Timber building systems can support a circular, regenerative economy.

Wood products are naturally renewable, reusable, biodegradable, and can be sustainably harvested. As a structural building material, wood is also well-suited to reconfiguration, reuse, and recovery. Considering the embodied energy represented by C&D waste, and the implications of continued materials disposal, wood’s adaptability makes it an effective building material for a low-carbon future.

There are many things to consider when looking at how wood can support a circular economy.

Wood is durable and long-lasting.

Wood is a resilient material that can provide decades, even centuries, of service when properly maintained. Ancient wood buildings continue to stand, including 8th century Japanese temples, 11th century Norwegian stave churches, and the many medieval post-and-beam structures of England and Europe. In surveys of building age, wood buildings consistently have the longest lifespans.

“Butler Square has been ahead of its time since the day it was built. As the fourth owner of this landmark building, I have continued this legacy by investing in ongoing upgrades to the building systems that have resulted in Butler Square becoming the first 100+-year-old, multi-tenant commercial building in the world to win LEED EB O&M certification and awards and accolades for its beauty, sustainability, and focus on healthy, high-performance operations, maintenance and management,” says Jane Mauer, president of Butler Properties. Photo courtesy of Butler Square

One contemporary example of wood’s long-lasting durability is Butler Square. Built more than 100 years ago as a warehouse for the Butler Brothers Company, this nine-story historic tall timber building in Minneapolis demonstrates how wood withstands the test of time.

While originally designed as a warehouse, the building has gone on to provide a range of uses. When truck transportation replaced rail in the region, the building’s urban location rendered it inefficient as a warehouse. In 1972 a renovation and adaptive reuse added a central atrium that draws in natural light, making it more marketable as retail and office space.

Smaller renovations and adaptations have continued over the years. Today the building is considered an architectural icon and continues to attract a wide range of tenants.

Butler Square has a “wide variety of tenants, from attorneys to advertising and architectural firms to computer consultants,” says Sonja Breyfogle, leasing associate with United Properties. “It appeals to a younger employee base as well as to tenants looking for more luxury type-A space.”

You can reduce waste with prefab wood.

Photo courtesy of DIRTT

Building with wood can help reduce construction waste through factory-built prefabrication, which can optimize assembly and streamline onsite erection.

“Renewable materials such as wood have been identified as an ideal construction material—especially when incorporating innovative mass timber products, design methods and processes like BIM and DfMA, tools for visualization such as VDC, and tools for manufacturing such as CNC,” writes architect Eduardo Souza.

These technologies can complement the environmental benefits of prefabricated timber systems, resulting in higher productivity, fewer change orders and issues during construction, higher quality, and reduced waste.

Wood waste can be reduced when design teams engage manufacturers early in the design process and incorporate the manufacturers’ standard product sizes efficiently in their designs.

One company with a commitment to waste reduction has turned its focus to the use of timber framed systems.

Photo courtesy of DIRTT

DIRTT (Doing It Right This Time) delivers fully customized interior environments for flexible office designs, healthcare facilities, educational environments, retail, and more. DIRTT was the first interior construction provider to complete a life cycle assessment and environmental product declaration.

DIRTT’s product line includes modular timber frame options including mezzanines and second floors, interior canopies, and timber accents for workstations and reading nooks. Their products and business model are rooted in efficiency and circularity:

“As a custom manufacturer, we recognize that we will always have some waste. However, we work diligently to reduce waste production and responsibly manage what we do generate. We aim to use packaging materials that are reusable or recyclable. We have extensive recycling programs throughout our facilities to divert materials from the landfill.”

Company designers and installers routinely re-visit customer spaces to reconfigure, upscale, or repurpose their products. DIRTT’s modular system can be modified onsite for new occupants or a change in the existing occupant’s needs, further reducing construction waste.

Timber is great for reuse.

Wood is a material well-suited to reuse, whether through the adaptive reuse of an existing structure or through deconstruction and disassembly.

In particular, long-standing heavy timber beams in existing buildings and structures are sought after for their durability, strength, aesthetic beauty, and historic significance.

Due to its rising value, companies like Unbuilders specialize in the deconstruction and reuse of this type of timber.

It has been said that the greenest buildings are the ones that already exist. Adaptive reuse is the process of redeveloping structurally sound older buildings for modern uses, infusing new life into a historic shell. Adaptive reuse can allow a project to significantly reduce its embodied carbon as well as the volume of materials sent to landfill through construction.

A compelling example of such an adaptive reuse is Milwaukee’s first mass timber building, Timber Lofts. The project combines a 130-year-old warehouse renovation with new mass timber construction in an adjacent parcel.

Photo by Roost Photography

“The idea from the onset was to harmonize the existing building with new construction,” says Tim Wolosz, principal at Engberg Anderson Architects.

In the renovation, individual boards were meticulously deconstructed from the warehouse, stacked, and set aside for cleaning and sandblasting to remove paint, exposing the wood’s maple grain.

After adding subflooring and sound control materials, the original wood floor was reinstalled. The original arched window openings, rolling fire doors, and exposed heavy timber frame, including wood joist rafters, also were preserved. The project shows how reclaimed wood and new mass timber construction can come together—full circle—reducing waste while delivering a modern building with historic charm.

Wood is easy to deconstruct and disassemble.

Wood is also well suited to deconstruction and disassembly when a building’s original service life ends. Modern wood buildings can be designed from modular components that can be refurbished as required or remanufactured into new products.

“We say ‘design for long life, loose fit.’ By using loose bolts, pins, and screws, and avoiding welding and friction-tight bolts, wood is easy to take apart,” says Greg Kingsley, structural engineer and CEO at KL&A Engineers and Builders.

The aim of Design for Disassembly, or DfDA, is the design of buildings to facilitate future change and the eventual dismantlement (in part or whole) for recovery of systems, components, and materials. DfDA offers flexibility, convertibility, addition, and subtraction of whole buildings.

- Transparency. Building systems that are visible and easy to identify.

- Regularity. Building systems and materials that are similar and laid out in regular, repeating patterns.

- Simplicity. Building systems and interconnections that are simple to understand, with a limited number of different material types and component sizes.

- Limited number of components. It is easier to dismantle structures that are composed of a smaller number of larger timber members. Conversely, in cases where deconstruction will likely be manual, it may be appropriate to design with smaller, lighter members.

- Easily separable materials. Materials should be easily separable into reusable components. Mechanical fasteners are preferable to adhesives. Composite materials can cause difficulty unless the composite assembly has reuse value as an assembly.

What about Industrial Buildings?

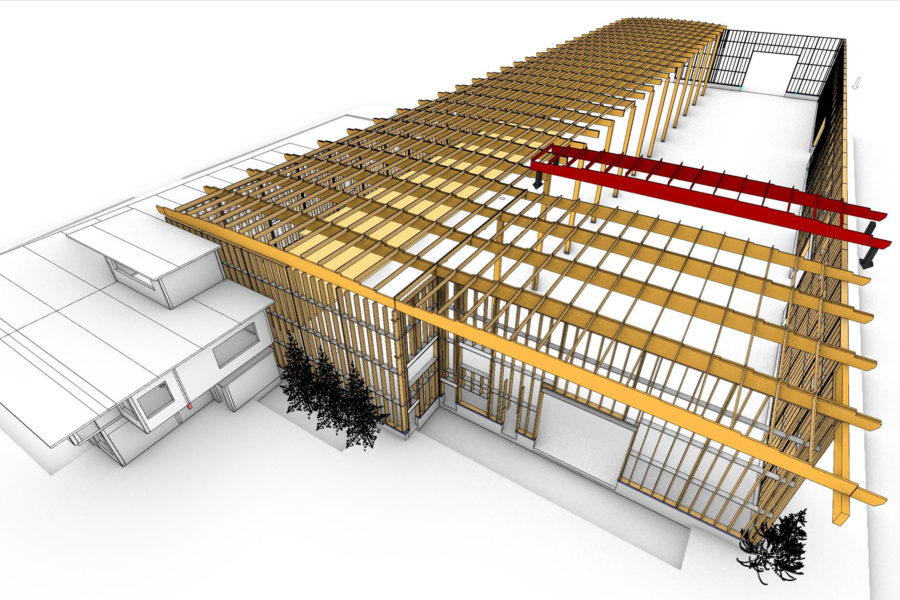

StructureCraft, an engineer-led fabricator of innovative timber structures, has set a new standard in industrial wood building design.

Photo courtesy of StructureCraft

The company’s 50,000-square-foot manufacturing facility showcases new levels of engineering efficiency for industrial buildings, combining a variety of mass timber and engineered wood products.

To demonstrate the flexibility of mass timber in industrial buildings, StructureCraft designed the entire building as a demountable structure, providing flexibility to expand or move the facility entirely to a new location.

The building was planned according to principles of design for deconstruction with the key features being reuse of existing structure in proposal, use of screwed steel connectors, and collaboration with contractor.

Image courtesy of StructureCraft

“The new facility was designed to explore what could be possible using wood for a simple industrial building with a tight budget. That exploration, while not simple during the design phase, has created a prototype which proves that modern industrial buildings may be created cost-effectively, and attractively, using wood.”

Reduce, Reuse, Recycle, Recover

Circular building. Photo courtesy of Arup

When materials reuse is not possible, bio-based materials components like wood can be recycled into other products including particle board and wood pellets or chips.

Energy can also be recovered from wood products in the form of biomass. Upon final disposal, bio-based materials can serve as fuel for microorganisms like termites and fungi, eventually degrading into biological nutrients.

There is a growing imperative in the AEC industry to shift to circular design principles to help reduce carbon emissions and excess material consumption and waste. Naturally renewable materials like wood can play an important role in making this transition a reality.

Strategies and Tools for the Future

- The AIA’s Zero Waste Design Guidelines are one example of how the industry is responding to help reduce waste and encourage circular design, including the reuse of wood featured in their case studies.

- Arup’s timber-built project, The Circular Building, is a fully demountable prototype showing how the circular economy can be applied to the built environment.

- Looking for more resources on wood reuse? The Building Materials Reuse Association’s reusewood.org outlines reuse and recycling options for wood and wood products.

The building and construction sector is massive and the pathway to a more circular economy can appear daunting and complex. Architect Clare Miflin—a key author of the Zero Waste Design Guidelines—reminds us, the basic principle remains simple: “Build less. For more people. Design circular.”