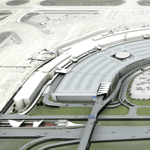

The entirety of Dallas/Fort Worth International Airport (DFW) is as big as Manhattan, so it gets to do things on a grand scale. The nation’s fourth busiest landing field is currently renovating four terminals and adjacent parking facilities, all built in the mid-1970s, and adding a rapid transit station. The $2.3 billion program will be completed by 2017, at which time significant reductions in energy and water will be realized.

“When the airport built the new Terminal D in 2005, it saw that it used nearly half as much energy as the other terminals,” says Julie Ludeman, communications director for the Terminal Renewal & Improvement Program (TRIP). Those efficiencies are now being applied to Terminals A, B, C, and E, and several parking facilities are being consolidated into energy-saving facilities that will feature some noticeable customer-service innovations.

In the process of renovating four terminals, DFW is incorporating new wayfinding signage, LED lighting, and plenty of windows to let in natural light.

The travel experience for most of us starts and ends with parking in the lots outside airports that seem to extend for miles with no end in sight. Answering the age-old problem of “Where did I leave my car?” will be a camera system that can answer that question through a mobile app. But just as meaningful, that same system can help arriving drivers determine where a space is without trolling the garage floor-by-floor. Of note, about three percent of spaces will be wired to accommodate electric vehicle-recharging.

The millions of travelers passing through the airport will be guided by backlit way-finding signage that is easier to read than current static signage. Using LED technology, the signs will require 70 percent less energy and much less maintenance than the fluorescent tubes they replace.

Throughout the horseshoe-shaped gate hubs, lighting is being configured to maximize natural daylight. Ceiling lamps have LED technology and use strategically distributed micro-grid sensors to dim the lighting according to the amount of sunshine already in the space.

Forty-year-old windows with low-E glass were replaced in the renovation, and fritting of the glass further reduces solar heat gain. Together, the initiatives save about 100 tons of cooling capacity per terminal. “We had to keep in mind the tasks of gate agents,” explains Tony Loyd, design lead on several segments of the project and managing principal from Jacobs Engineering, which is the lead firm on the project. “Reflectivity of their computer screens was an issue for us, which required some experimentation.”

Cooling of the terminals is also modernized with an innovative fan-wall technology that enables less temperature variation and easier maintenance. A test of the system in late 2011 identified a 35 percent decrease in energy for cooling the facility. Low-flow toilets and sinks with hand sensors reduced water use by 40 percent. Reclaimed water from Fort Worth is used for cooling in the airport’s Central Utility Plant and for watering landscaping, which is made up of native species of plants appropriate for airports (i.e., less habitable for birds, a hazard to air traffic). With all of these sustainable features, DFW might be the same size as Manhattan, but it is certainly working to be greener.