Story at a glance:

- Kynar Aquatec promotes excellent weatherability, color retention, and abrasion resistance.

- APV Engineered Coatings created 40 custom-color NeverFade formulas to match the original colors of one condo building in need of a refresh.

From freshening a building’s facade to providing decades-long protection against weathering, the right exterior paint can deliver sustainable performance benefits for commercial, institutional, and residential buildings.

Crucial to sustainable exterior paint performance is the use of polyvinylidene fluoride (PVDF) resin technology. Consider Kynar Aquatec® PVDF resin—a tough, engineered thermoplastic polymer with super-strong carbon-fluorine bonds that do not break down under exposure to the elements.

Kynar Aquatec promotes excellent weatherability, color retention, and abrasion resistance. It is a key ingredient in NeverFade® Exterior Paints, allowing the paints to outlast high-performance urethane and acrylic latex-based paints, even when exposed to extreme UV rays, high temperature, humidity and abrasion.

Here are a few examples of how the performance advantages of NeverFade Exterior Paints with Kynar Aquatec—coupled with the attention and dedication of skilled painting contractors—met the needs of three common exterior painting challenges.

Challenge 1: Creating a Colorful Facade

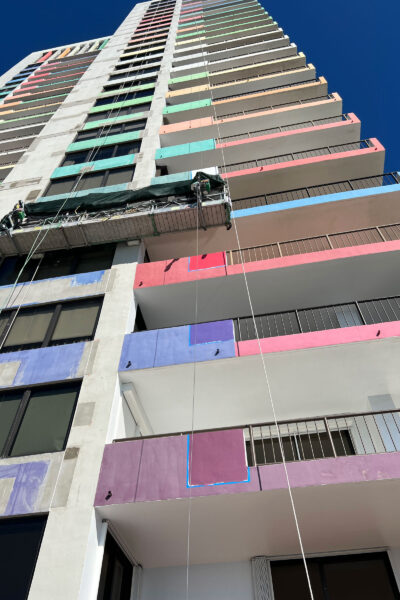

Villa Regina’s 40 colors range from a citrusy yellow to a deep purple and every shade in between. Photo courtesy of Villa Regina Condominium

Case Study: Villa Regina Condominium

The Villa Regina Condominium in Miami features a 300,000-square-foot artistic masterpiece on its facade. Over time the sunny, humid, salt-air-laden climate took its toll on the colorful, kinetic creation, fading the original colors by 20 Delta E units over seven years and leading to a costly and disruptive cycle of repainting.

To reduce that costly cycle of repainting, the condominium turned to PVDF-based paint. APV Engineered Coatings was tasked with creating 40 custom-color NeverFade formulas to match the original colors. APV chemists and color specialists worked diligently in the lab over a period of three weeks to get the colors perfect, using a combination of art and science. Once they had a base formula developed, they employed a photo spectrometer to guide the right amounts of red, yellow, and blue pigment to add, and adjusted each color’s shade, tint and tone. Then, using expertise developed over decades of color-matching experience, they used their artistic eye to make sure the paint colors matched reference colors perfectly—not just in the lab, but also outdoors in ambient light conditions.

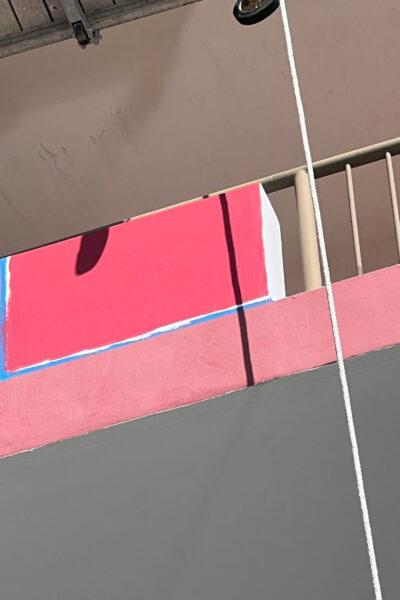

To ensure the NeverFade paints would apply at the proper thickness and match the intended colors once installed and dry, the project team coated small mock-up sections for approval by the condo board. As soon as the mock-up sections were done, the color difference between the original, faded acrylic paint and the new NeverFade topcoat was dramatic.

- During the mock-up process, the project team completed small sections of each color. Photo courtesy of Lazer Mfg.

- Side-by-side comparisons show the visible difference between the original faded acrylic paint and the new NeverFade PVDF-based coating. Photo courtesy Lazer Mfg.

“The condominium board is extremely pleased to see the eye-catching colors, and our overall efforts to maintain the building,” says Villa Regina’s general manager John R. Fernandez. “Even beyond our tenants we’re getting a lot of great buzz from other property managers and area residents who are excited to see our landmark taken to the next level in long-term sustainability.”

Case Study: JAFCO

- Before: After five years in the hot Florida sun, the paint on the building’s exterior had faded, chalked and deteriorated. Photo courtesy of APV Engineered Coatings

- The bold, rich color of the new coating system will stand up to years of damaging UV rays. Photo courtesy of APV Engineered Coatings

Florida’s climate also took its toll on The Jewish Adoption and Foster Care Options (JAFCO) Children’s Ability Center in Broward County. Its bright-hued red, orange, yellow, and blue stucco facade—originally painted with an acrylic-based coating—had significantly faded, chalked, and deteriorated after only five years.

The original paint came with a very limited 10-year warranty that did not cover color fading, and the product manufacturer could not precisely match the specified color. The project team—tasked with finding a restoration solution that would stand the test of time—turned to APV and NeverFade.

“The high-performance NeverFade topcoat had a creamy, rich texture with excellent workability and flowability,” says Norge Arnaiz, principal of Restore Construction Group. “The coating evenly covered the building’s stucco profile and kept a nice wet edge with no roller marks, which is a challenge in the hot, humid Florida climate.”

“Our intent was to be budget conscious while providing a long-lasting beautiful aesthetic,” says JAFCO’s Facilities Director Michael Moran. “The high-performance coating will not only retain its vibrant colorful appeal for a very long time but also provide significant cost savings by not having to repaint the facility every five years, which is a typical coating life cycle in Florida.”

Challenge #2: Painting a Complicated Building Structure

The full-scale exterior restoration of the Turlington Building had to pause three times as hurricanes swept through the area. Photo courtesy of MLD Architects

Maintaining a nice, wet edge in hot, humid conditions is only one advantage of NeverFade. Another is the fact that it is a one-component, water-based, air-dry system. Two-component systems become tacky quickly, making them difficult to roll on and making application almost impossible.

That advantage was important for the Villa Regina repainting project, where the project team paid special attention to film thickness as well as environmental conditions like the temperature of the surface being coated and the amount of moisture in the environment.

Case Study: Turlington Building

It also was important for the team painting The Ralph D. Turlington Florida Education Center (Turlington Building) in Tallahassee, Florida. The iconic building’s multi-angled, 18-story structure features a highly pitched roofline that was challenging to paint.

“Our swing stages only reached the 16th floor of the 18-story building, so we had an additional crew of up to 6 rappelers on bosun chairs working on higher levels,” says Randall Gardner, project manager at All Trades Historical Restoration. “Given these conditions and the extreme sun and wind, we needed a coating formula that would be easy to apply via roller, at the appropriate film thickness and with a quick dry time, but not so quick that we couldn’t maintain uniform coverage across the panels. NeverFade Exterior Paints with Kynar Aquatec fit the bill perfectly.”

Challenge #3: Painting Metal Substrates

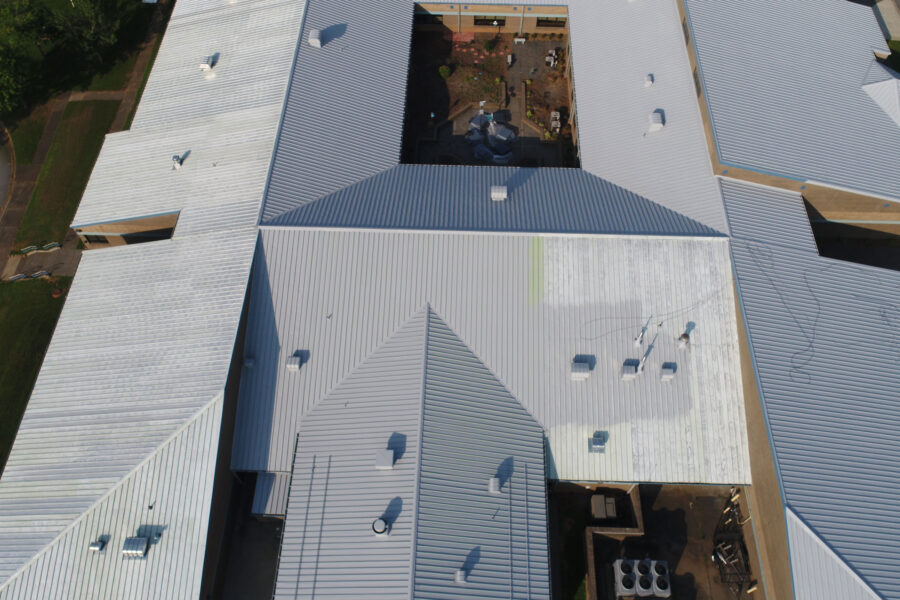

- After 25 years of service life the metal roof on Central Middle School in Dobson, North Carolina, was showing its age. Photo courtesy of APV Engineered Coatings

- The school has a fresh, new look after the roof coating project was completed. Photo courtesy of APV Engineered Coatings

The protection benefits of Kynar Aquatec PVDF resin used in NeverFade are like those of solvent-based Kynar 500® PVDF resin-based coatings, which have been used in factory finishes on exterior metal building materials like aluminum doors and window frames for six decades. Today Kynar Aquatec allows specifiers to get similar performance in a water-based resin formulated for field applications.

The resin’s trusted performance was one reason the architect in charge of restoring the Turlington Building’s metal panels chose NeverFade to closely match the factory-applied finish. While other paints and coatings under consideration failed tape adhesion testing and lacked the smooth finish and uniformity of the Kynar Aquatec–based coating, NeverFade provided a great end result.

Compatibility with metal surfaces also was key for the team in charge of recoating Central Middle School in Dobson, North Carolina, where back-to-back winters with heavy snow and ice caused the blue, factory-applied coating on the standing seam roof to flake and peel off, exposing large sections of grey primer and the underlying steel roof panels to the elements.

It’s easy to use, easy to spray, and has a phenomenal finish.

After stripping the old paint from the roof, the project team thoroughly pressure-washed the entire surface to ensure no paint remover or residual materials remained. Then, they sprayed a coat of APV’s W-1650 Bonding Primer at a thickness of 1.5 to 2.0 mils. The primer is designed to adhere to tough surfaces, including metal and pre-coated metal. Its water-based, low-VOC chemistry provides early water resistance, protects against corrosion, and applies with a smooth, uniform finish for optimum aesthetics.

Next they spray-applied two 2.5-3.0 mil layers of NeverFade Metal Restoration Topcoat—engineered for coated or uncoated ferrous and non-ferrous metal surfaces—in a custom-tinted blue color to perfectly match the roof panels’ original factory finish.

“We’ve worked with other fluoropolymer coatings before, but NeverFade is by far the best,” says Joe Brindle, president at Custom Coatings. “It’s easy to use, easy to spray, and has a phenomenal finish that looks just like a new, factory-coated metal roof.”