[Photo: Courtesy of Filtration Group]

Filtration Group’s complete line of filters improves air quality and occupant comfort.

The World Health Organization recently estimated that in 2016 as many as 4.2 million premature deaths occurred worldwide as a result of air pollution, and the EPA says prolonged exposure to poor indoor air quality can result in a slew of debilitating maladies—including respiratory dysfunction, heart disease, and cancer.

It’s all part of why global manufacturing company Filtration Group takes building cutting-edge air filters so seriously—pushing the envelope on a product that, in the past, has often been considered little more than a mass market commodity. “The primary concern of many customers is the up-front price of the filter,” says Michael Bruce, director of product and channel marketing at Filtration Group. “But that’s only because they are uneducated about so many other factors that go into air filtration.”

The factors Bruce refers to are manifold, including cost implications of energy usage, filter life expectancy, and removal and disposal. There are additional factors relating to Indoor Air Quality (IAQ), such as the filters’ MERV (Minimum Efficiency Reporting Value)—a metric established by ASHRAE to measure air filtration efficiency.

Filtration Group manufactures an extensive line of pleated air filters, which use folds in their media to pack more surface area into a single frame, allowing for a higher dust holding capacity (DHC) that results in better filtration and a longer product lifespan.

And while this labyrinth of considerations may seem daunting, Filtration Group’s diverse line of products offers a solution for every application, meaning that customers can breathe easy.

FROM OUR MAY+JUNE 2019 ISSUE

The preferred publication of leading green professionals.

[Photo: Courtesy of Filtration Group]

MERV 10 NOVA-PLEAT® X

Most prominent among Filtration Group’s suite of options is its new MERV 10 NOVAPLEAT X self-supported filter, released in March 2019.

Compared to Filtration Group’s MERV 8 NOVAPLEAT, the new NOVAPLEAT X promises to capture 20% more particles in the ASHRAE spectrum. In other words, the NOVAPLEAT X not only protects HVAC equipment more effectively; it can make downstream efficiency filters last longer, and do so without losses in energy efficiency while improving Indoor Air Quality (IAQ). The NOVAPLEAT X is also designed for automation, meaning it’s machine-made using a streamlined process.

While air filters have traditionally been built with wirebacked grid to support their form, beginning in the late 1990s, self-supported filters emerged on the market. As environmental pressures increased over the subsequent decades, it became clear that these air filters also offered another benefit: waste reduction. The galvanized steel used to build wirebacked filters can contain toxic heavy metals that often wind up in a landfill, but self-supported filters are fully incinerable.

All the same, self-supported filters didn’t come without their drawbacks. Due to the stiffer media required to allow the filters to hold their shapes without a wire backing, airflow resistance was increased, resulting in what’s called a high pressure drop. Given that energy costs can make up as much as 90% of a filter’s total cost of ownership, the small savings on the initial filter price were hardly worth it, particularly in markets with high electricity rates, like the northeastern U.S.

However, technology has come a long way since those days, and the new NOVAPLEAT X filter promises to provide all the benefits of a self-supported filter while side-stepping the disadvantages similar products have been plagued by in the past.

The trick is in Filtration Group’s innovative synthetic media, which uses smaller fibers that are more densely aligned in order to beat the odds. According to Dave Heritage, head of sales for national accounts at Filtration Group, it was the company’s access to other technologies within the filtration space, the result of a series of private equity acquisitions, that allowed their technology to move forward so rapidly.

“It’s logical to think that as you go up in MERV, you also go up in resistance, and until recently that has generally been the case,” he says. “What’s going on now is that, as a result of R&D investments that have happened over the past two decades, we’re seeing the last of the buggy manufacturers and the first of the car manufacturers.”

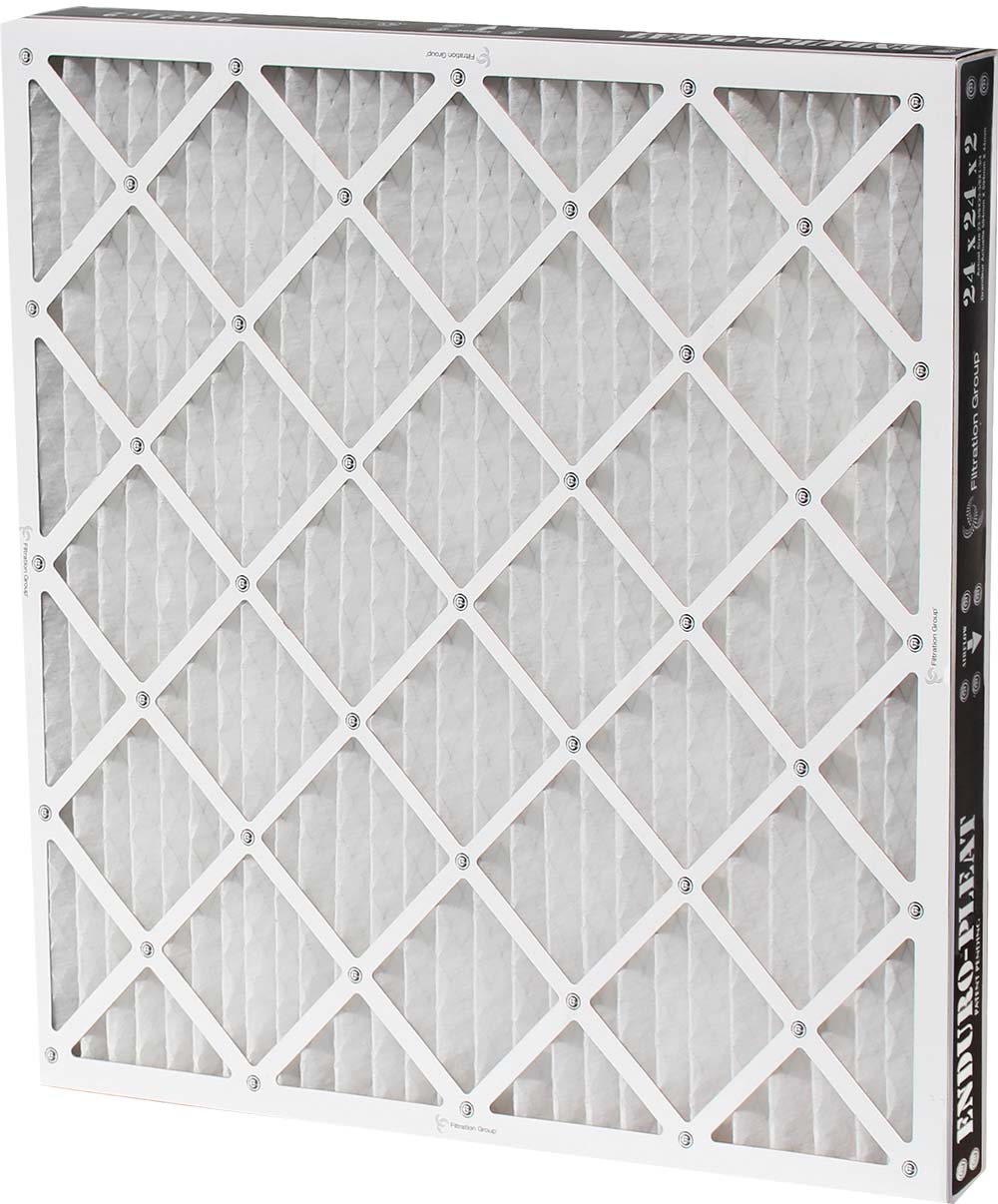

The ENDURO-PLEAT is a wirebacked filter with a long lifespan. [Photo: Courtesy of Filtration Group]

MERV 8 ENDURO-PLEAT®

Beyond their low total cost of ownership and environmental benefits, self-supported pleats have another

advantage: durability.

While typical wirebacked filters may get crushed or bent out of shape during shipment, self-supported filters easily retain their original form, even after being crushed or battered. Moreover, sharp tips of wire that become exposed on damaged wirebacked filters prior to disposal can create a safety hazard for laborers, a non-issue with self-supported filters.

But for the most rugged applications wirebacked filters may still be best, and to serve those needs, Filtration Group offers another product—the MERV 8 ENDURO-PLEAT. The ENDURO-PLEAT is a wirebacked filter built using ultra-strong beverage board and heavier or thicker steel as well as a specialty media with a higher DHC than other models to prolong its lifespan and allow it to withstand extreme conditions.

The filter’s hearty construction and high-capacity media can grant it a lifespan of anywhere between six to 12 months, meaning customers who invest in the ENDURO-PLEAT can expect to better protect their equipment, spend less money on labor and disposal, and lower their environmental footprint.

“A standard pleated filter might work well in a lab environment, but when it’s installed on a rooftop in Chicago and it’s pelted with snow, it could collapse,” Heritage says. “A filter that lasts three months in a relatively calm environment might last three weeks in a chaotic one. If we can put in a filter that lasts three times as long, that makes a significant difference to customers.”

The GREEN PLEAT pulls in dust in much the same way static electricity makes hair cling to a balloon. [Photo: Courtesy of Filtration Group]

MERV 13 GREEN PLEAT

While MERV 8 and MERV 10 filters are a strong option for residential and commercial properties alike, those looking to get closer to LEED certification may want to purchase a filter with a rating of MERV 13 or higher, a designation best served by Filtration Group’s wirebacked Aerostar® GREEN PLEAT filter.

The GREEN PLEAT attracts ultra-small particles by using electret-charged media, a technology that pulls in dust in much the same way static electricity makes hair cling to a balloon when it’s rubbed on someone’s head.

By utilizing this media, the GREEN PLEAT can allow particulate matter smaller than 2.5 microns—PM 2.5 for short—to be removed from the air with up to 90% efficiency. To grant some perspective, even a grain of salt is a full 70 microns in size. At 1/30th the size of a human hair, thousands of particles in the PM 2.5 range could fit within a single period at the end of this sentence.

“Particles that are bigger than PM 2.5 get stopped by your human filters—either the nose or the bronchial tubes,” Bruce says. “But when we talk about PM 2.5 and below, these are particles that can get into your bloodstream and are linkable to health issues defined by sick building syndrome.”

And while these health concerns alone might be enough to convince many to upgrade to a MERV 13 filter, sick building syndrome—the tendency for workers to experience headaches, fatigue, and other health effects when exposed to unhealthy indoor environments—has an impact on more than individual well-being. A Harvard study published in 2015 linked poor indoor air quality to lower productivity, further proving that the air we breathe in offices has a big effect on how well we work.

[Photo: Courtesy of Filtration Group]

MORE SPECIAL PLEATS

In addition to the core product line, Filtration Group also offers several filters for specialty applications that have become increasingly important in industrial settings and areas with wildfires, like California. These include the Series 550 Odor Removal Pleat and the Series 750 Plus Carbon Pleat. The Series 550 Odor Removal Pleat is also popular in casinos looking to remove smoke from their atmosphere and hospitality settings interested in creating an optimal environment for their patrons.

Heritage says that as time presses on, the winds of change will continue to blow, and Filtration Group will keep diversifying its product line. “We will continue to push efficiencies higher and resistance lower,” he says. “There is a perfect state out there in which every particle is captured with zero resistance. That might not exist, but we’re going to continue getting closer.”