Story at a glance:

- Architects and engineers have moved beyond LEED certifications and other benchmarks to seek improvements in sustainability wherever they can be found.

- USG—a legacy manufacturer of wallboard, ceiling solutions, and other building materials—is leading product innovations that can help customers achieve a range of sustainable goals.

- A future-proof built environment offers its occupants safety and health while adapting to shifting demands and environmental conditions.

No one can predict what the future holds. Science can point to potential problems, but the built environment must anticipate the emerging realities of climate change, conservation, and occupant needs. That’s why the best strategy is often to continually pursue improvements in environmental performance.

Sustainable practices have been part of USG’s processes since the company’s inception more than 120 years ago. “The company started this journey way back—when people were not as aware of sustainability,” says Srinivas “Dr. Vas” Veeramasuneni, USG’s chief technology officer.

A brand synonymous with safety and performance, USG Corporation put its longstanding sustainable practices front-and-center when it introduced recycled paper facings on its category-defining wallboard, Sheetrock® Brand.

Awareness blossomed more recently when architects, engineers, and clients started looking to meet LEED standards and other benchmarks. “Early on sustainability was largely associated with achieving certifications,” says Katie Mesia, design resilience leader and principal at global architecture and design firm Gensler. “Over time early benchmarks became foundational, and the goalpost for aspirational performance has moved steadily higher.”

Meeting the Trend

Mass timber construction is in process here on the jobsite. Photo by Fungi Media, courtesy of USG Corporation

As the concept of sustainability went from buzzword to what Chris Griffin, USG president and CEO, calls an “undeniable trend,” the company on its own accord formalized its efforts to make its operations even more environmentally friendly. USG published its first formal sustainability report in 2010, targeting a 20% reduction in greenhouse gas (GHG) emissions across the board by 2020.

USG accomplished this by making huge strides in product development and manufacturing, reducing the weight of core offerings up to 40% without sacrificing strength. “That reduces the amount of energy we use to make our product, saves transportation energy, and makes it easy for customers to install,” Griffin says. “And when you reduce the raw materials used, it saves mined materials for future generations.”

USG has now reconfirmed its push toward long-range sustainability, targeting Science-Based Target initiative benchmarks aligned to the Paris Climate Accords. By investing in new processes, using raw materials with lower embodied carbon, and shifting to environmentally friendly transportation methods, USG plans to reduce manufacturing GHG emissions an additional 30% by the end of the decade.

“We re-upped and set some ambitious targets for 2030 and have a goal of net zero by 2045,” Griffin says. “CO2 reduction is at the core of the effort, but we now think a bit more broadly around our people, our planet, and the profitability of our business.”

Spending to Save

New capital investments are making manufacturing operations state-of-the-industry in earth-friendliness. Griffin talks about the company’s intentional process of generational decision-making. “At USG we think about how sustainability benefits our company as well as our customers,” Griffin says. “It drives where we invest, particularly in continuously improving and innovating across products and processes.”

“We want to innovate starting from our mining operations,” Veeramasuneni adds. “How do we manufacture differently? How do we design products differently? How do we ship differently? These are not easy challenges, but we look at them holistically. When you have a holistic view, that’s where we can make things future-proof.”

Touting Transparency

USG Levelrock Brand 2500 Gypsum Underlayment. Photo by Fungi Media, courtesy of USG Corporation

To help its customers choose more sustainable products, USG has championed a new era of corporate transparency. Publishing Environmental Product Declarations (EPDs) for its entire product portfolio, the company is helping customers choose products that reduce environmental impacts and prioritize the health and safety of indoor environments.

Nearly all USG products have EPDs, accessed easily from a continuously updated corporate sustainability tool. “People can select products from our portfolio to meet the goals they are trying to achieve,” Veeramasuneni says. “If they want LEED Silver, we have products that can meet that goal.”

Such transparency helps designers make informed decisions, whatever a client’s objectives may be. “Achieving zero-impact targets involves precise, nuanced discussions, often requiring trade-offs between different sustainability goals,” Mesia says. “When clients set clear targets it facilitates conversations around resilient design, energy reliability, and long-term, operational sustainability.”

Circular Logic

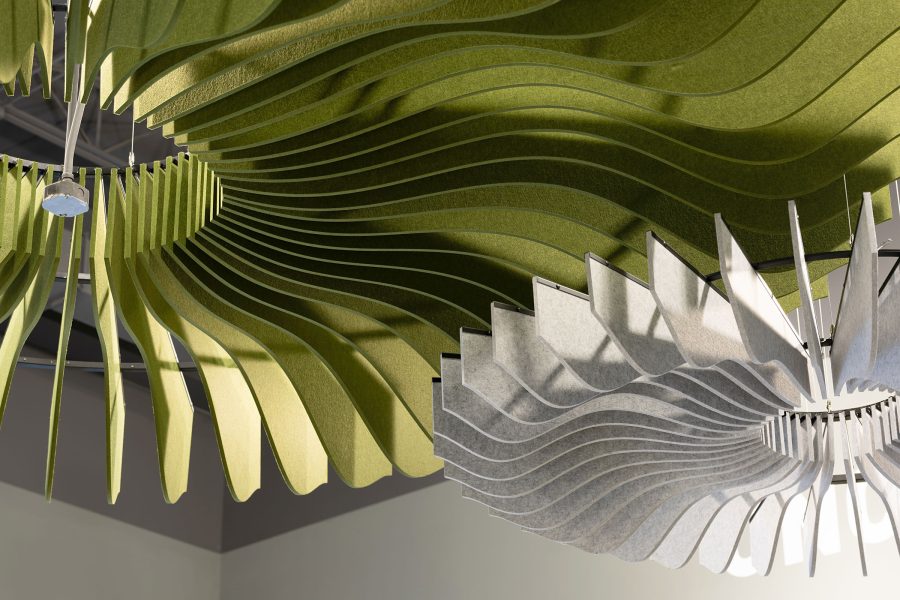

Radialz acoustic assembly solutions make a statement. Photo by Fungi Media, courtesy of USG Corporation

Scrap represents a significant portion of the wallboard and other materials used on a project, so USG is scaling up a takeback program launched in 2023. The program reclaims clean scrap to produce new materials, preventing site waste from going to landfills, saving customers money on landfill fees, and supporting their green goals.

“Big companies like Google and Amazon were asking general contractors if they were going to buy gypsum board or drywall from a manufacturer who can take back the waste from their job sites,” Veeramasuneni says. “We stepped up.”

Reclaiming used product from a jobsite is more challenging, Veeramasuneni adds, but USG is looking for new ways to achieve zero waste. “We keep safety first, then focus on quality and performance. That’s why we have been focusing on new construction waste. We’ll explore opportunities to reuse or recycle other types of waste in the future.”

People First

USG Mars High-NRC Acoustical Panels are fine-textured panels designed to offer the highest standard in noise reduction or noise isolation. Rendering courtesy of USG Corporation 2023

A future-proof structure is one that offers users lasting cultural significance. “By embracing adaptability, resilience, and the capacity to foster meaningful connections, buildings remain economically viable, relevant to evolving community needs, and poised for changing environmental conditions,” Mesia says.

USG ultimately hopes to help create spaces that nurture a sense of community, foster inclusion, and promote physical safety and well-being. With its 2030 targets USG established safety assessments for all raw materials; only when chemists approve a component for use is it included in a formulation. “We want to give customers the products they are going to use day in, day out,” Griffin says. “We don’t use any chemicals that create or cause harm to our employees.”

Half of what the company makes goes into new homes, so that scrutiny extends to occupant safety and health. “We spend more time inside than outside,” Veeramasuneni says. “The products we make for interior applications have to have very low levels of VOCs.”

Shared Progress

Working with startups, government agencies, customers, and vendors, USG will continue to seek innovations that promise to reduce its carbon footprint and help customers do the same. USG exists to help its global customers more easily and safely create sustainable and accessible spaces for all. USG will share its progress toward its 2030 goals every year.

Sustainability gives us a lot of constraints, and constraints drive innovation.

“This is not just us saying we’re going to do these things,” Veeramasuneni says. “We do these things because our customers want it. USG has always had a lens on sustainability—and if you have sustainability, you can differentiate your products and make great progress.”

“Sustainability gives us a lot of constraints, and constraints drive innovation,” he adds. “Sustainability is a part of our bigger strategy. We have a triple bottom line: people, planet, and profitability.”

The Three Cs

USG’s efforts target carbon, customers, and circularity. “It goes back to being good business,” Griffin says. “Carbon is expensive. Our people, our customers, and the market are going to continue to demand better, more sustainable products. When we take the carbon out and improve sustainability, we lower costs and improve profitability.

“The advantage we have is that we’re a first mover. We invented lightweight wallboard. We invented a lightweight joint compound. But that doesn’t mean we’re not looking beyond that. Dr. Vas and the almost 100 scientists at our Corporate Innovation Center are looking for the next moonshot.”

“We’re tasked with growing our business and applying these principles on a broader scale,” Griffin says. “It’s the sustainability of our business and the sustainability of the planet. We’re proud of our legacy, but it’s a daunting responsibility: How do you carry this on for the next 100 years? We’re working on it every day.”