Story at a glance:

- Ross Barney Architects designed a rural community college to prepare students for careers in both traditional and emerging technologies.

- The McHenry County College Foglia Center for Advanced Technology and Innovation project was designed to achieve LEED Gold.

- The result is a flexible, future-ready educational building designed to support advanced manufacturing, robotics, welding, digital media, and multidisciplinary workforce programs.

The Foglia Center for Advanced Technology and Innovation (CATI) at McHenry County College (MCC) in Crystal Lake, Illinois, is a showcase for old and new technologies, skills, and trades.

MCC plays a critical role in the local economy by teaching real-world skills and preparing students for careers in advanced technology and manufacturing. The college has made important strategic relationships with local manufacturers who have expressed a significant need for this type of training, and the CATI was designed to help MCC serve this mission. The classrooms and laboratories support courses in welding, heating and cooling systems, industrial maintenance, engineering technology, construction management, artificial intelligence, metallurgy, and metrology.

Aiming for Gold

Translucent polycarbonate exterior wall panels allow glare-free daylighting throughout the high bay laboratories and the tiered collaboration space. Photo by Kendall McCaugherty, Hall+Merrick+McCaugherty; courtesy of Ross Barney Architects

Ross Barney Architects designed the Foglia Center for Advanced Technology and Innovation at McHenry County College in Crystal Lake, Illinois, to showcase for old and new technologies, skills, and trades. Photo by Kendall McCaugherty, Hall+Merrick+McCaugherty; courtesy of Ross Barney Architects

Sustainability was a primary goal for McHenry County College, with LEED Silver as the initially proposed level of certification. Through a holistic, integrated design approach, and without additional cost, the team was able to target LEED Gold; the project is pending final review from the USGBC.

This integrated design approach began with broad stakeholder engagement to identify the project goals and desired outcomes, which, in addition to the lofty sustainability goals, included expanding the understanding of what manufacturing means for the students and public, welcoming the community, and demonstrating building and system technologies as a teaching tool.

McHenry County College Foglia Center for Advanced Technology and Innovation is focused on preparing students for careers in welding, HVAC systems, industrial maintenance, engineering technology, construction management, artificial intelligence, metallurgy, metrology, and more. Photo by Kendall McCaugherty, Hall+Merrick+McCaugherty; courtesy of Ross Barney Architects

Showcasing and providing visibility into the high bay CNC, welding, and HVAC laboratories were primary design features. A maker space, operated in collaboration with the Griffin Museum of Science and Industry and open to the public as well as enrolled students, is located at the main entry to the building. Also at the main entry, an open stair and tiered seating serve as a gathering, collaboration, and lecture space, and catwalks accessible from the upper-level corridor allow visitors and students to observe the high bay laboratories and building mechanical spaces from above.

Key stakeholders from the college were instrumental in this goal-setting effort as well as the development of the design. MCC President Clinton Gabbard consistently pushed for design excellence and a facility that would captivate students, staff, and visitors alike, and faculty members worked hands-on with our design team at Ross Barney Architects to optimize the layouts and configurations of the laboratories and classrooms.

Materials & Design Strategies

- Photo by Kendall McCaugherty, Hall+Merrick+McCaugherty; courtesy of Ross Barney Architects

- Photo by Kendall McCaugherty, Hall+Merrick+McCaugherty; courtesy of Ross Barney Architects

The project design and public bidding occurred during the Covid pandemic, so managing volatile construction cost increases was a primary challenge. Our main cost-saving effort consisted of making the programmed areas as spatially efficient as possible. For the three high-bay laboratories, which represent the largest amount of programmed area, we worked directly with the faculty to lay out major pieces of equipment and eliminate wasted space at the onset of the project.

This exercise allowed us to reduce the initially programmed square footage of these three spaces by more than 1,000 square feet. Applying this same collaborative approach to the remainder of the programmed areas allowed us to reduce the total building square footage by more than 10% from the college’s original program.

Applied materials, particularly finishes, add significant cost to a construction project. On public projects where budgets are limited and maintenance is an ongoing concern, we often look to utilize natural materials that are expressive, durable, sustainable, and cost effective.

Color, where utilized is purposeful: The large construction yellow volumes that contain computer labs assist with wayfinding and express the industrial nature of the building’s program. Masonry veneer, translucent polycarbonate wall panels, corrugated metal panels, polished concrete, and exposed steel deck comprise the building’s material palette.

We prioritized incorporating products from manufacturers that provided Environmental Product Declarations and sourcing transparency, allowing us to target five of six possible LEED Materials and Resources – Building Product Disclosure and Optimization credits. These materials were also selected for their benefit to indoor air quality; all three LEED Indoor Environmental Quality – Low Emitting Materials points were targeted.

On public projects where budgets are limited and maintenance is an ongoing concern, we often look to utilize natural materials that are expressive, durable, sustainable, and cost effective.

The continuous clerestory along the building’s main circulation axis is a nod to monitor skylights that are often seen in industrial buildings and provides daylighting for collaboration and study spaces that are located at the center of the plan. By pulling the second-floor circulation away from the high bay volume, daylight reaches the lower floor collaboration and study areas from above. Translucent polycarbonate exterior wall panels allow glare-free daylighting throughout the high bay laboratories and the tiered collaboration space.

Additional sustainable strategies included the use of an energy-efficient, decoupled HVAC system that uses DOAS ventilation and an air-cooled heat recovery VRF system with indoor fan coil units and roof mounted condensers for space heating and cooling. This approach allowed our team to target 16 of 18 total points for the LEED Energy and Atmosphere – Optimize Energy Performance credit. The ventilation strategy, which incorporated outdoor air and increases the number of air changes per hour, exceeds ASHRAE 62.1-2016 requirements, allowing us to target the LEED Pilot credit for Indoor Air Quality and Infection Control.

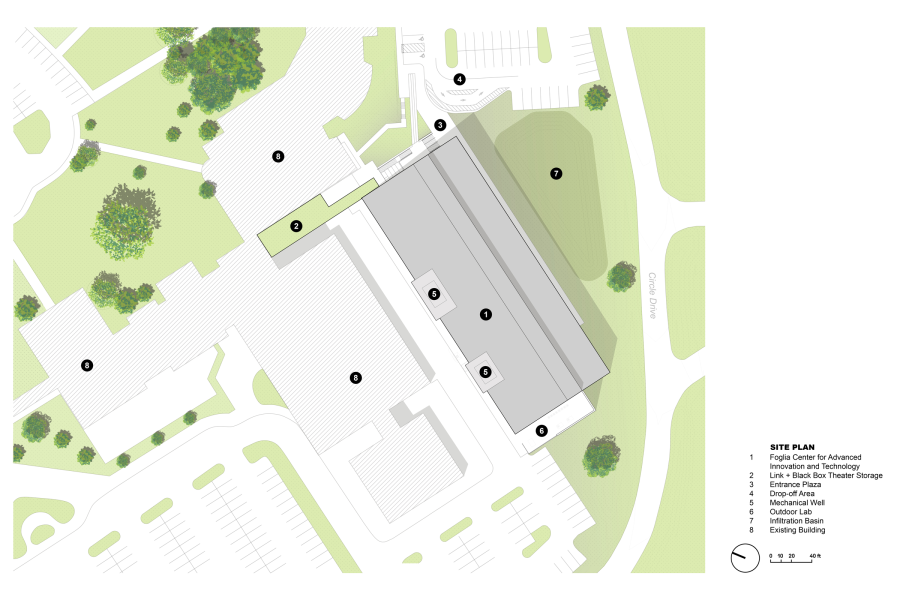

The CATI incorporates a single-story pedestrian link that serves as a weather-protected and accessible route to on-campus amenities. Despite being an isolated commuter campus, no new parking spaces were provided for the project. Instead, the open space adjacent to the building is dedicated to sustainable stormwater management. An infiltration basin, planted with native plants to attract pollinators, provide visual interest, and eliminate the need for outdoor water usage, is located directly adjacent to the building. Stormwater is collected and treated onsite prior to recharging the groundwater. By also selecting high-albedo site surface and roof materials and full-cutoff exterior lighting fixtures, we were able to target achieving all 10 LEED Sustainable Sites credits.

The result of this integrated design effort, with the strategic incorporation of sustainable features, is a state-of-the-art facility that will provide equitable career and continuing education opportunities and serve as a beacon for excellence in teaching, learning, training, and attracting and retaining a talented workforce for the innovative local manufacturing economy for years to come.

Ross Barney Architects used color with intention on this community college project. Yellow helps with wayfinding and expresses the industrial nature of the building’s program. Photo by Kendall McCaugherty, Hall+Merrick+McCaugherty; courtesy of Ross Barney Architects

Site plan courtesy of Ross Barney Architects