GAF offers sustainable and innovative roofing solutions for residential and commercial projects alike.

[Photo: Courtesy of GAF]

The roofs on buildings, all buildings, perform multiple jobs. All are expected to keep the weather out. But depending on the building itself, we expect many other things from what’s on top of where we live, work, play, shop, attend school, worship, and do business.

We ask a lot of our roofs, but our requests are increasingly demanding and varied. This is why a leading manufacturer in the roofing industry, GAF (a subsidiary of Standard Industries), invests so heavily in research and development. The $3 billion company, based in Parsippany, New Jersey, is the largest manufacturer of commercial and residential roofing in North America.

More than 75 employees in five locations are tasked with developing longer lasting, higher performing, and more economical roofing shingles (sloped roofs, mostly residential) and membranes (flatter roofs, largely used on larger commercial structures).

[Photo: Courtesy of GAF]

Focus on Sustainability

“Fifty to 70% of our research is focused on sustainability,” says Dan Boss, senior vice president of research and development. “That includes enhancing reflectivity, increasing R-values (insulation effectiveness), reducing the use of solvents, and improving upon durability over the lifetime of a roofing system.”

GAF is committed to sustainability in all areas of its business by developing energy-efficient technologies and Red List–free products, optimizing the use of materials, engaging in recycling initiatives, and helping roofing contractors do the same.

All of that is important to product development, Boss says. But this is not a cookie-cutter scenario, just as no two buildings are alike. “Different buildings have different problems,” he says. “What’s needed on a tall tower is going to be different from what goes on a big-box store. We try to walk in a building owner’s shoes to find the right solution for their specific needs.”

[Photo: Courtesy of GAF]

Innovative Roofing Solutions

Some of the newer technological innovations from GAF address the residential market, largely defined as steep-slope roofing. Boss cites DecoTech™, a low-profile solar system that visually and physically integrates into the roof itself, as among the R&D team’s top priorities. Also, Timberline HD® Reflector Series™ Shingles, which can be used to comply with California Title 24 cool roof requirements and come in a variety of dark, vibrant colors that are new to cool roofs.

But when it comes to those huge flat and low-sloped roofs, things get even more interesting. Boss’ colleague, Michelle Carlin, senior product manager of coatings, points out that there are millions of low slope roofs in the U.S. The older roofs might use less reflective surfaces, which gradually are being replaced with more reflective single-ply roofing membranes or restored with reflective liquid applied roofing products.

GAF has expanded its EnergyGuard™ polyiso product line by adding a variety of EnergyGuard™ NH Polyiso insulation boards that are Red List–free, have been issued a Declare label and a Health Product Declaration, and can contribute to achieving LEED® v4 and Living Building Challenge certifications.

Another is EverGuard Extreme® TPO, a single-ply thermoplastic polyolefin roofing membrane specially designed with solar installations in mind. Thanks to proprietary stabilizers and ultraviolet light absorbers, the material performs well in high heat applications like roofs that include building-integrated solar systems. As solar energy continues its double-digit growth on large, flat roofs, this product in particular will complement that growth by easing building owner concerns.

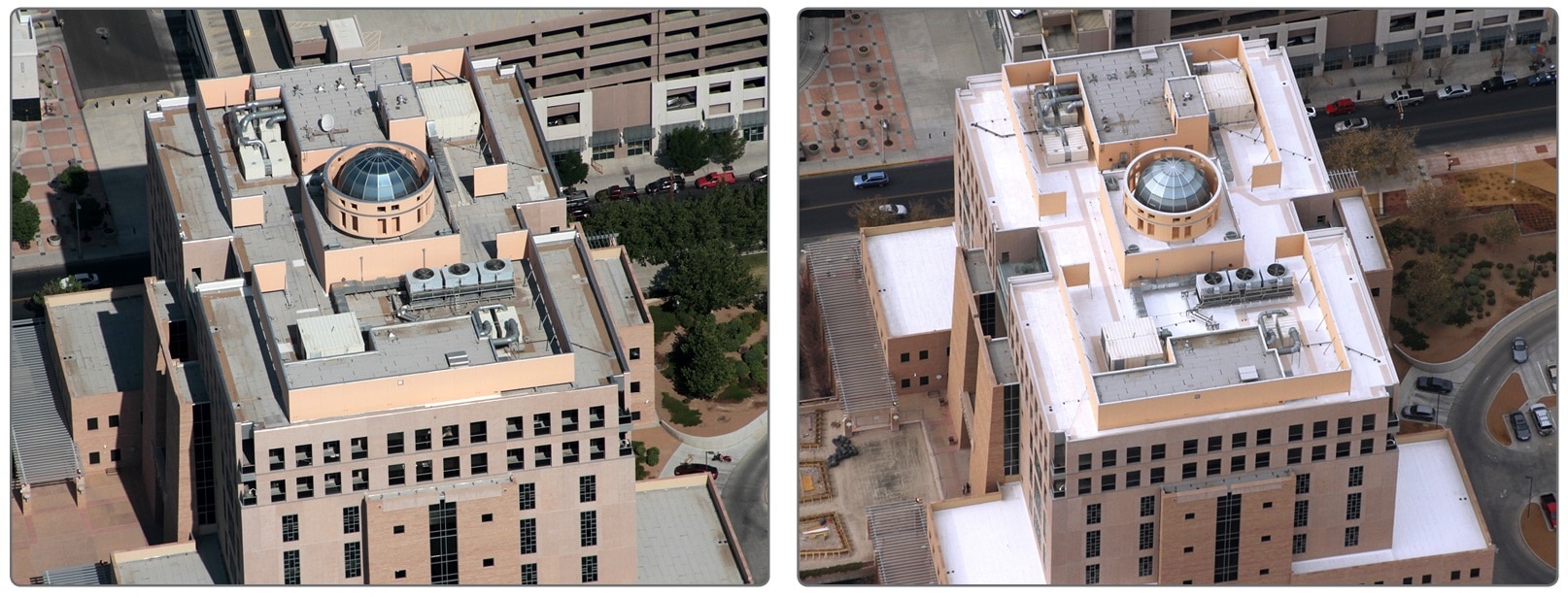

An aerial view of before and after GAF roofing solutions. [Photo: Courtesy of GAF]

The company also offers the HydroStop® Premium-Coat® System, a fabric-reinforced liquid applied system that can be used to restore roofs that may be exhibiting some signs of wear and tear while providing the benefits of reflectivity and helping to reduce waste produced by tear-offs.

Carlin emphasizes the economics of roofs and roofing materials as a key driver for adoption of GAF’s innovative sustainability-oriented materials and systems.

“While some of the products can be a little more expensive than traditional products, the long-term benefits, like the potential for cooling cost savings and stress reduction on HVAC equipment, are very appealing,” she says.

Boss agrees, reminding us again that every roof is different. “Most facilities managers want to do the sustainable thing,” he says. “But it has to be reliable, and it has to be cost effective.”

Read more about GAF and catch up on more gb&d roofing stories.