Duro-Last outfitted Green Garage, a coworking space in Detroit, with a new roof to keep out heat and meet all of the organization’s sustainability needs.

[Courtesy of Duro-Last]

The Green Garage in Detroit needed a tough membrane to keep out the elements and support sustainable amenities. Duro-Last gave it all that and then-some with this green roof.

Download a PDF of this story.

Download a PDF of this story.

Learn more about green roof solutions at duro-last.com.

Pity the poor roof. It has such a big job to do and gets overlooked (under-looked?) by almost everyone.

That wasn’t the case, however, for early planners of Green Garage in Detroit. As they redeveloped this circa-1920 structure, the idea was to create a co-working space for businesses and nonprofits that endeavor to make the Motor City sustainable. Originally an auto showroom and service station, the building went through several phases of use and deterioration—with a roof that needed a serious update. “The old asphalt roof wasn’t in the best shape,” says Matthew Piper, director of communications, operations, and business development for Green Garage. “More than that, we wanted a roof that wouldn’t contribute to heat gain in the building or to the urban heat island effect. It needed to reflect rather than absorb heat.”

“There is greater consistency in the weld, it allows for faster installation, and generates less waste on-site.”

Katie Chapman, sustainability specialist

That much was accomplished with a custom fabricated, PVC membrane manufactured about 100 miles north in Saginaw, Michigan, by Duro-Last, Inc.—the world’s largest manufacturer of custom-fabricated single-ply roofing systems. The white, 40-mil PVC material (0.04 inch thickness) might seem a humble building feature, but how it’s made and what it accomplishes is in sync with what Green Garage stands for.

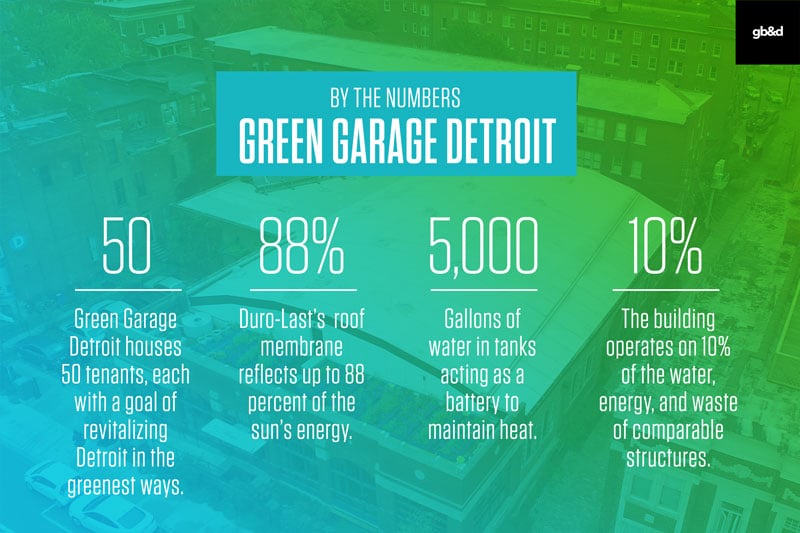

Green Garage houses nearly 50 tenants, each with a goal of revitalizing Detroit in the greenest ways. This includes the Detroit Food Academy, promoting food-related and social entrepreneurship; Fresh Corner Café, providing access to healthy foods; and the Great Lakes Environmental Law Center, a freshwater advocacy organization.

Operating Efficiently

The building operates on 10% of the water, energy, and waste of comparable structures. It was renovated from 2008 to 2011 with the help of 200 volunteers who assisted private developers Peggy and Tom Brennan in transforming the 12,500-square-foot space. Scrap wood from the renovation was used to build an accent wall, and fallen trees in nearby southeast Michigan make up the wood floor.

[Courtesy of Duro-Last]

BY THE NUMBERS

The Green Garage used solar thermal panels, not photovoltaics, as they were cheaper to install and allowed for a radiant loop heating system beneath the facility. Details:

5,000

Gallons of water in tanks acting as a battery to maintain heat.

90

Degrees minimum temperature of water in the panels before it triggers the pump to circulate the heated fluid to the storage tanks.

60 to 70

Degrees of incline in the vertical positioning of the panels, which is roughly set at the latitude of the location, plus or minus 15 degrees.

Just as important, highly efficient walls and windows made for a tight building envelope, and the roof needed to be equally green. The Duro-Last single-ply roofing membrane is the only product on the market that can be custom-made to fit the entire roofing system, an important feature in and weather resiliency and water tightness.

“These are not rolls but customized sheets designed to fit the roof perfectly,” explains Katie Chapman, a Duro-Last sustainability specialist. “That means there is greater consistency in the weld, it allows for faster installation, and generates less waste on-site.”

While the product is available in five colors, Green Garage selected white for its Energy Star rating for reflectivity. “We wanted a roof that wouldn’t contribute to heat gain in the building or to the urban heat island effect,” Piper says. “It needed to reflect, rather than absorb, heat.”

Rooftop Perks

Green Garage had additional goals. Solar thermal panels were installed on a flat portion of the roof. Ten collectors each weigh about 185 pounds, including the hardware, framing, and water, which circulates heat through radiant loops under the floors of the main building and around the perimeter of the side/annex building. The flat-roof portion also has a working rooftop farm. It’s not a vegetated roof exactly, but has a series of small, recycled shipping containers from General Motors Co. where lettuce, basil, borage, kale, chervil, and more are grown.

“Because we needed to build the new roof on top of the existing one, the roof material also needed to be relatively lightweight for the building’s internal trusses to support it,” Piper says. The Duro-Last product fit this need, adding little weight (0.33 pounds per square-foot) while being resilient to the stresses of the garden and solar features.

The roof also incorporated 16 Solatubes, tubular daylighting devices (TDDs) also known as “sun pipes” that bring natural light into the building. Light monitors and skylights were considered, but they added design complexity to the barrel roof and the low insulation values (R5) of skylights and monitors compared poorly to the rest of the roof (R-55). Solatubes, with 21-inch-diameter globes, had a lesser heat-loss effect.

As even the smaller TDDs required holes be cut into the roofing membrane, Duro-Last custom flashings were used to fit the tube holes and ensure water tightness. “It’s important for people to have access to natural light while they work,” Piper says. “On sunny days we’ll turn the main lights off in the building and just rely on the light from the windows and Solatubes.”