No matter the project type, plumbing engineers and contractors aim to provide clients with high-quality project design and end results that have lasting value, all while maintaining profitability. Product quality plays a key role in achieving these goals, but many engineers and contractors may not have considered how a single-source supplier could impact project efficiency and profitability.

Being proactive and finding ways to streamline specification processes will assist in building and maintaining a profitable construction and engineering firm while ensuring superior project results.

The Meaning of The Power of One

An important consideration when designing plumbing systems is to identify a single-source manufacturer, especially for commercial applications like health care or hospitality. Using a “one-stop-shop” that offers a range of plumbing products that work well in commercial applications will help streamline projects.

A manufacturer could bundle health care rooms and offer a range of plumbing products that work well in, for example, health care applications, from ADA-compliant tubular products, cements, and sealants to drains and testing products.

Photo courtesy of Oatey Co.

No two construction projects are the same, and the demands and requirements of a commercial project are even more unique. These projects entail innovative solutions and an expert team to ensure the project is completed on time, within budget, and built to rigorous specifications.

Oatey Commercial is a single-source supplier that helps engineers and contractors face the many challenges of commercial construction. If engineers can specify plumbing products from start to finish working with one manufacturer, the project team will be counting on a single sales contact and supplier.

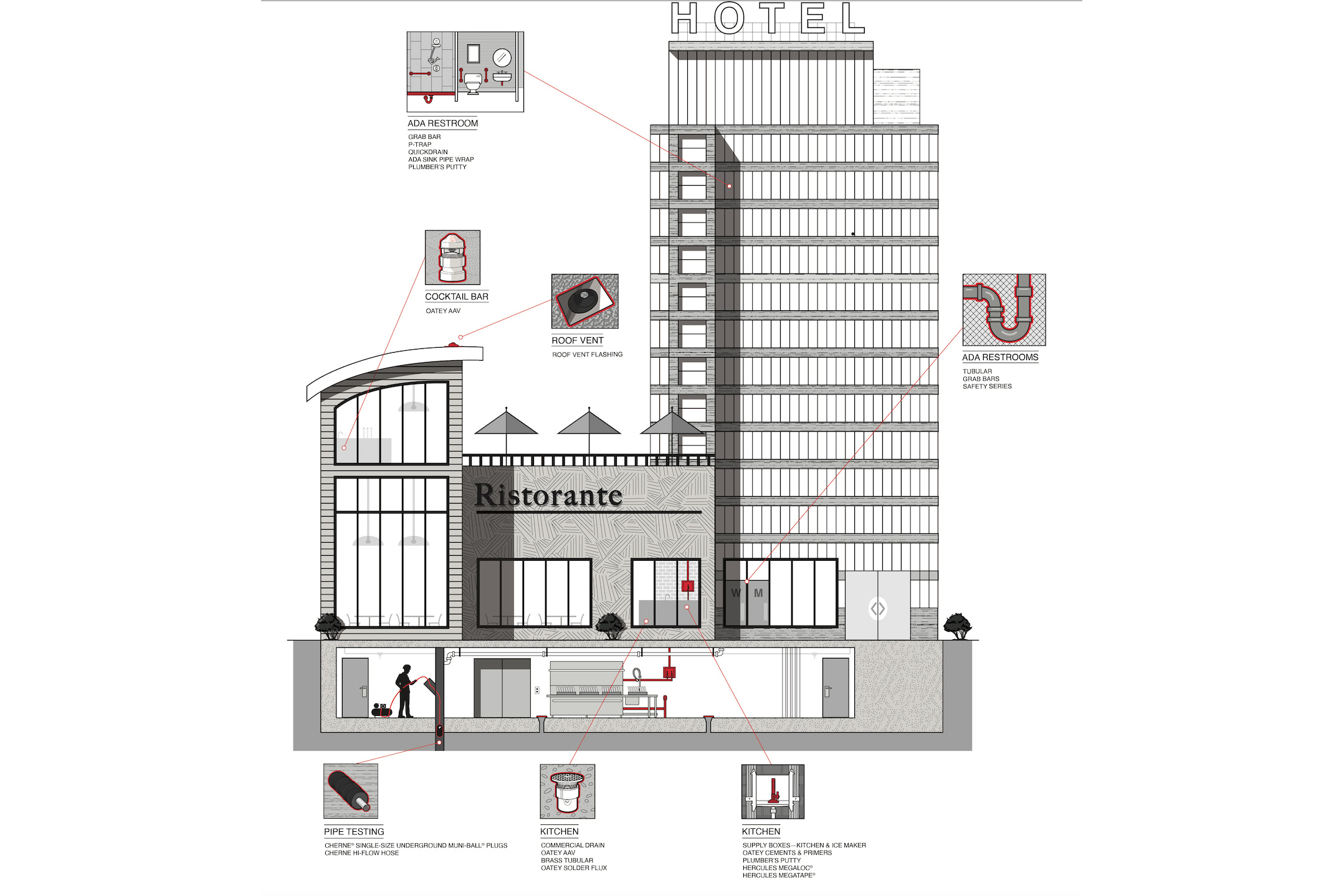

When specifying plumbing products for a hospitality project, the main focus would likely be the rooms and bathrooms within the hotel. However, plumbing products will also need to be specified for kitchen or restaurant/bar construction.

Photo courtesy of Oatey Co.

With a single-source supplier, you could specify solvent cement, primers, thread sealants, commercial tubular, grab bars, air admittance valves, supply boxes, rough-in products, drainage, and even test plugs, all from one manufacturer or supplier. Not only will this bundling process streamline specifications for engineers, but it will also have a significant impact on the efficiency of project management from the general contractor’s perspective.

The below graphic illustrates how some of Oatey’s plumbing products can be applied to different aspects of a hotel project.

Graphic courtesy of Oatey Co.

Now that we have a better understanding of the meaning of a single-source manufacturer, let’s dive into three ways it can streamline specification and increase profitability for plumbing engineers and contractors.

1. One point-of-contact and nurtured relationships

Engineers find value in a strong relationship with the manufacturer whose product they specify and with the local rep agency representing those products.

Say you are specifying a supply box. You want to be confident that particular supply box is a quality product with a good company backing it up. While there are instances where you would specify one specific manufacturer’s product, finding a partner that can bundle products for your projects ensures you always work with one point of contact.

Instead of specifying a supply box from this company, a hammer arrester from that company, a drain from another, and so forth, a single-source can ensure you don’t end up communicating with three or four representatives while trying to build and nurture those relationships.

The power of one means you have one relationship that provides you several avenues of specifications you could stand behind, knowing it’s a great company with great people, and that you are specifying quality products. The power of one also means that if there’s a product question or a need for troubleshooting, you’re going to one website or reaching out via one email every time.

In short, it helps streamline the process, plus you’re going to one place for any maintenance or technical questions down the line. Whether you are a specifier, a wholesaler, or a contractor, you know the customer service number to get you the help you need.

2. Streamline purchase orders and shipping

While this might not necessarily be something to consider at the specifying level, a single-source manufacturer can also have a significant impact at the project construction level.

By the time a product is specified and a contractor decides they’re going to use it, they have to work with a wholesaler to source the materials and submit a PEO for the products they’re using.

When buying a supply box here or a hammer arrester there, construction firms and project managers will likely deal with different shipments and payments, while a single-source supplier translates into one purchase order through one wholesaler that comes on one shipment. That’s a one-stop-shop.

Usually a wholesaler will already have the necessary products in stock. But for bigger commercial jobs, they likely have to order certain products. That’s where shipments can impact productivity and efficiency. You don’t want to be tracking 17 pallets and how they are getting from a manufacturer’s distribution center to the wholesaler to the contractor to the job site.

In addition, you usually must hit a minimum quantity to earn free freight through wholesalers. That might be hard to do if you’re buying individual pieces and parts from one wholesaler. But when you’re bundling products for an entire job through a single manufacturer, the freight will add up fast and could result in free shipping.

3. Technical resources

A single-source manufacturer will get you quick, professional answers to your questions to keep projects moving forward. From planning and designing to specifying, one call does it all.

Construction teams count on reliable products to keep projects running smoothly and require the most accurate information to specify products for jobs. Dealing with one manufacturer streamlines planning and specifications, because all resources can be found in one place, one website with detailed product descriptions, educational information, how-to videos, and new-product updates. Plus, construction teams can find the tools they need in one place, including:

- BIMSmith

- MasterSpec

- ARCAT

- ARCOM

- 3-Part CSIs

- Specifications

In conclusion, a one-stop-shop ensures you have support at every level. Whether you are a specifier, contractor, or wholesaler, you’re getting help the same way through one avenue at every step of your project.

A project with issues down the line could negatively affect your firm’s reputation. As you work to streamline your specifications, strengthen relationships, and specify trustworthy products, you will protect your projects long-term and build a reputation for prioritizing high-quality results.