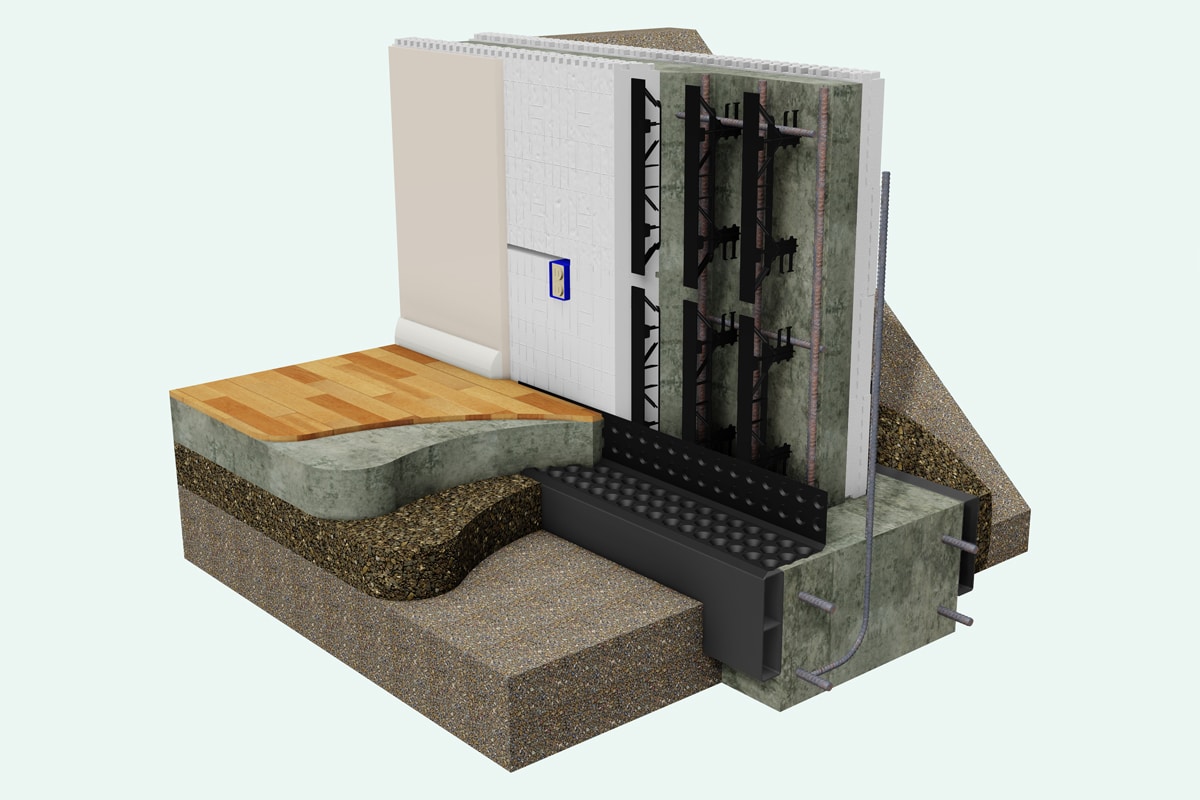

In 2016 the ICFMA commissioned an independent scientific study comparing a wood-framed cavity wall to a standard six-inch core ICF wall. Photo courtesy of IFCMA

The Insulating Concrete Forms Manufacturers Association (ICFMA) is the North American nonprofit trade association for the ICF industry, founded in 2014 by a group of manufacturers who are committed to improving the quality of and spreading the word about ICF construction. For starters, advocates like Brian Corder, marketing chair of the ICFMA and president of BuildBlock, want people to know how ICFs punch above their weight class—with a material R-value of R-23 or R-24 (higher than more conventional walls, which are typically R-20) and deliver performance from R-45 to R-55. We talked to Corder about why this matters and how ICFs lead to 50% more in energy savings. Even though R-values are close, the thermal mass of the concrete moves ICFs into a class of its own.

We’ve long known ICFs are an energy-efficient building solution, but a recent study showed just how sustainable they are, as ICF walls actively resist changing temperature while delivering higher R-values than alternative insulation materials. From a structural standpoint, ICFs are no different than having a poured concrete wall, and the dense concrete core is surrounded by EPS foam insulation that doesn’t degrade. Heat moves in and out of a building in three ways: conduction, convection, and radiation. Foam insulation is the only building material that effectively stops all three.

At the CLEB Lab in Quebec, researchers discovered just how well an ICF wall performs. We compared a two-by-six traditionally insulated framed cavity wall with a standard six-inch core ICF wall. The wall was cooled to negative 35 degrees on one side and room temperature maintained on the other to see when the wall would reach a steady state. How long would it take before they had to add energy to maintain a 70-degree room temperature? After approximately 60 hours, the wood-framed wall reached steady state and was cold. The ICF wall reached steady state after 300 hours.

Photo courtesy of IFCMA

When you have a solid mass wall that never changes temperature because it’s airtight and insulated from temperature changes, you’re significantly reducing the strain on your HVAC system. We recently replaced the geothermal system in one of our office buildings, and we didn’t have heat in the 22,000-square-foot building for about a week. The temperature was in the teens, but even with no heat, the temperature inside never got below 65 degrees thanks to ICFs. You can have a structural wall that delivers between an R-45 and R-55 with no more investment in materials and less investment in labor. If you want to design a building that will deliver extremely high energy performance, ICFs offer all of this and more.

Read more from Insulating Concrete Forms Manufacturers Association (ICFMA) in the November + December issue of gb&d where they discussed building with ICFs.