In a large industrial space, selecting the wrong lights can waste significant energy—and dollars.

Replacing old fluorescents with Flex Lighting Solutions’ Essentials Series 4.0 LED High Bays increased light levels by 80% at Dana Incorporated. [Photo: Courtesy of Future Energy Group]

It’s a good time to be shopping for industrial lighting.

That’s because in just the last few years, LED technology has advanced by leaps and bounds, leading to dramatically higher efficiencies with improved consistency and longevity. Half a decade ago it would take three years or more for reduced energy costs to pay back an average investment in LED lighting for an industrial or commercial space, according to Christopher Stratas, general manager of Flex Lighting Solutions. Today, you get that return on investment in almost half the time—the LED lighting is that much more efficient and cost effective.

“We consider it kind of a no-brainer to upgrade,” he says. “You’re not going to be sitting here three to four years from now saying, ‘I wish I waited.’”

In addition to the increased efficiency, modern LEDs don’t depreciate like fluorescent or high-intensity discharge (HID) sources did in the past, so consistent light levels are maintained for a much longer time, without the need for lamp replacements.

The time is right. But how do you know where to begin when you’re shopping for lights for your factory, warehouse, commercial, or industrial space?

“First and foremost, we want to understand the light levels a customer needs,” says Greg Aufderheide, director of business development for North America at Flex Lighting Solutions. Some customers will have a target light level, while others may not know exactly what they want. That’s where the experts at Flex come into play, creating a computer simulation to show customers exactly how various light options would look in their space.

For Dana Incorporated, the results of replacing old fluorescents with Flex Lighting Solution’s Essentials Series 4.0 LED High Bays were clear immediately, with light levels increased by 80%. “From day one, since the new Flex high bays were installed, the employees have been really happy and mentioned how bright it is,” says Paula Zuccaro, engineering assistant at Dana Incorporated. “They have increased visibility in their work cells, which improved

their performance.”

And beyond boosting employee morale, the sustainable solution will pay off for the manufacturing facility, which operates 24 hours a day, seven days a week. The new lights are expected to save 449,880-kilowatt hours of energy each year.

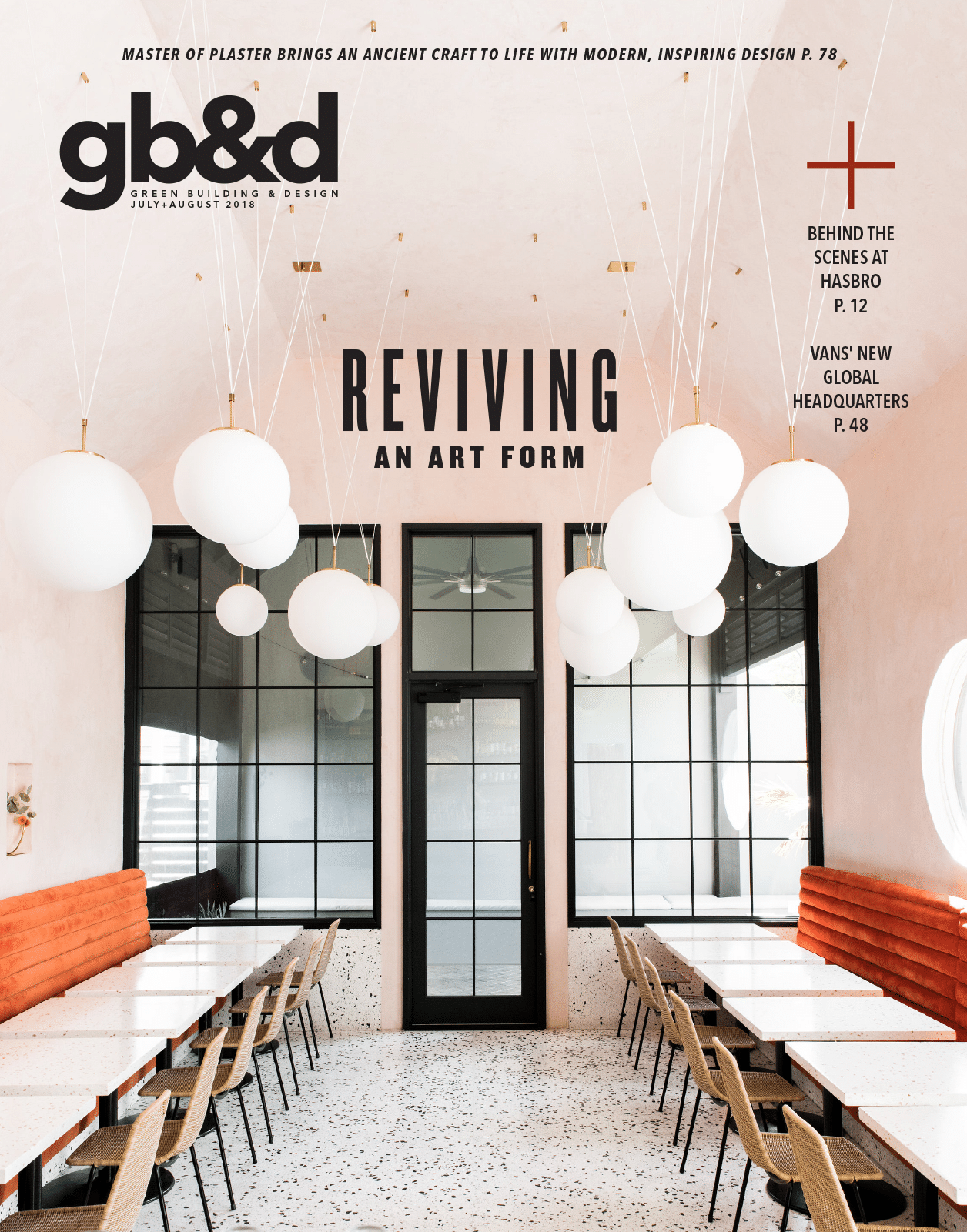

FROM OUR JULY+AUGUST 2018 ISSUE

Flex Lighting Solutions has transformed countless spaces, including Delaco Steel. [Photo: Courtesy of Future Energy Group]

1: Is it a new project or a retrofit?

If it’s a new build, you can configure the lighting to precisely meet the needs of the space. When replacing existing lighting, however, you are faced with fitting the new lights into the existing configuration or rewiring the facility. Given the expense of rewiring, most customers will opt for new lights that fit directly into the existing layout. Flex’s products are designed to be used both in new installations and one-for-one replacements, Stratas says, making for a streamlined installation.

2: Is the space air-conditioned?

Many industrial spaces aren’t climate-controlled, resulting in what’s known as a high ambient condition. In other words, it’s hot. Typical high bay lights are installed some 25 feet in the air, Aufderheide notes, and temperatures can rise well over 100 degrees Fahrenheit up there. In order to perform optimally, the lights need to be rated to meet these conditions. Flex’s products feature a thermal management technology that makes sure the light will operate efficiently even on the hottest days.

3: Is there any safety concern?

A bright, well-lit workspace will boost employee productivity, and it can also keep them safe. When Dana Incorporated set out to replace the lighting in its 1-million-square-foot manufacturing facility, safety was a top priority. The team worked with Flex to design a system that featured a lighted path of egress that would allow workers to evacuate in case of an emergency loss of power.

4: What about controls?

Depending on how the space is used, a simple on-off switch may be the only control you need. In areas that aren’t always occupied, fixture mounted sensors can turn off or dim the lights when the area is vacant. In other applications, though, you may want to connect your lighting system to an Internet of Things (IoT) network or building management system, so the lighting can be controlled and monitored remotely.

The HT1 Series is perfectly suited for auto showrooms, big-box retailers, convention centers, and more. These High Bay LED luminaires come in a stylish troffer design for high ceiling applications that require superior lumen output, ultra-long life, and high quality of light. [Photo: Courtesy of Flex Lighting Solutions]

Flex Lighting Solution’s Essentials Series 4.0 is the newest generation of the Essentials Series. These LED fixtures deliver best-in-class thermal management for ambient temperatures up to 65°C, provide the highest reliability and best lumen maintenance, and offer the lowest TCO. [Photo: Courtesy of Flex Lighting Solutions]

3 Ways Flex Lighting’s Luminaires are Superior

1: They can take the heat. Flex Lighting’s luminaires have better thermal management and perform well in harsh environments. Flex Essentials Series 4.0 LED High Bays have up to a 65ºC (149ºF) max. ambient rating.

2: They’re reliable. Flex Lighting’s luminaires are durable and built with high-quality components, leading to much longer, maintenance-free operation than competitors’ products.

3: They’re compact in design. The low-profile luminaires are small but mighty, with high lumen output and high efficacy.

All of the lights: What you need to know about the three main types of high-bay lighting.

- High-Intensity Discharge (HID): Traditional lights, often metal-halide or high-pressure sodium, degrade fairly quickly. They also have a long warm-up time. In order to achieve the same lighting level in a 250,000-square-foot facility, HIDs would consume 229,216 watts of power.

- Fluorescent: While it was introduced as an alternative to HID lights, fluorescent is no longer the most efficient option. In order to achieve the same lighting level in a 250,000-square-foot facility, fluorescent lights would consume 181,764 watts of power.

- LED: LEDs offer instant-on lighting, and the lumen output will remain consistent over time. Technology gains mean these lights consume far less energy than HID or fluorescents. In order to achieve the same lighting level in a 250,000-square-foot facility, LEDs like Flex’s Essential Series 4.0 consume just 48,642 watts of power.