IntelliDeck solutions are lower maintenance and more sustainable. [Photo: Courtesy of IntelliDeck]

Maintenance and performance issues plague outdoor living for homeowners and condo associations. But IntelliDeck is changing all that.

Rooftop decks typically add an average of 6 to 8% to the value of condominiums, according to a report by CNBC’s real estate reporter Diana Olick. And many realestate consultants interviewed say rooftop decks shorten the sales period and are important selling points in urban and rural areas alike.

But not all decking material is the same, and the differences have significant environmental and financial effects. A few years ago, the product development people at O’Sullivan Films recognized problems with two predominant decking materials—pressure treated lumber and composite decks, the latter a combination of wood sawdust and plastic. O’Sullivan used a waterproof membrane material devised more than 25 years ago in industrial and commercial settings but determined in 2015 that a residential version could offer a lower-maintenance and greener alternative to wood and composite decking.

They gave it a name, IntelliDeck, and it’s changing decks as we know them. “This is a code-approved, walkable rooftop membrane,” says Kyle Lancaster, the exterior business unit manager for the Washington, DC-area firm. He says it ideally works on any elevated deck, creating a dry space beneath it, from suburban backyard patios and pools to rooftop decks on gleaming high-rises.

FROM OUR JANUARY+FEBRUARY 2018 ISSUE

The preferred publication of leading green professionals.

[Photo: Courtesy of IntelliDeck]

Multiple Solutions

IntelliDeck is luxury vinyl outdoor flooring, a membrane with a PVC layer and 3-ounce non-woven polyester back layer that promotes glue adhesion. The facing is printed with a variety of wood grain, stone, and pebble designs. But aside from aesthetics, it solves a number of environmental issues.

The big problem with wood decks is they require annual staining or sealing to prevent mold and other deterioration. The stains may have high levels of volatile organic compounds, too. Because traditional planking has open slots between planks, rainfall leads to deterioration. Consequently, the support joists, which are hard to protect with annual maintenance, can fail from rot.

With composite planking, the substructure (made of wood) is also subject to rainfall—and it’s also the most expensive choice. Composite material also responds to temperature fluctuations, so it needs to have larger gaps between planks; this has the consequence of trapping debris. If the deck is largely in the shade, mold can result, and if it’s in the sun, the surface can be too hot for bare feet.

“This is a code-approved, walkable rooftop membrane.”

—

Kyle Lancaster, IntelliDeck

One installer who has firsthand knowledge of negative consequences from composite decks is Grant Barlow of MyWaterproofDeck.com. He’s well established in the business of building decks, and he now uses IntelliDeck over or in place of composites and treated lumber.

“I have many years experience with wood and composite decking,” says Barlow, who operates out of Wellsville, Ohio. “Over time moisture causes rotting, mold, and movement of supporting joists.” While the product can be installed over existing decks and concrete, it uses untreated lumber and plywood (not oriented strand board) as a substrate in a new-build project. To avoid puddling, the deck needs a standard 2% slope downward, away from buildings and toward the desired drainage area.

[Photo: Courtesy of IntelliDeck]

A Better Pool Deck

Slip and fall accidents are no joke, particularly around backyard pools. Neither are leaky concrete decks that surround them.

A 40-year-old condominium pool deck in Ocean City, New Jersey, had been given liquid surface coatings multiple times over the years. Seasonal expansions and contractions caused 1.5-inch gaps that were sure to grow over time. With 6,000 square feet of surface, it was a lot to worry about.

Trained IntelliDeck installer Grant Barlow was able to cover the entire area in just a few days (a 12-hour training program enables installers to provide up to a 30-year guarantee to customers). Water seepage in the concrete stopped immediately, while the condo association was assured that IntelliDeck not only meets the International Code Council requirements for slip resistance, it actually is more resistant when wet.

[Photo: Courtesy of IntelliDeck]

How it Works

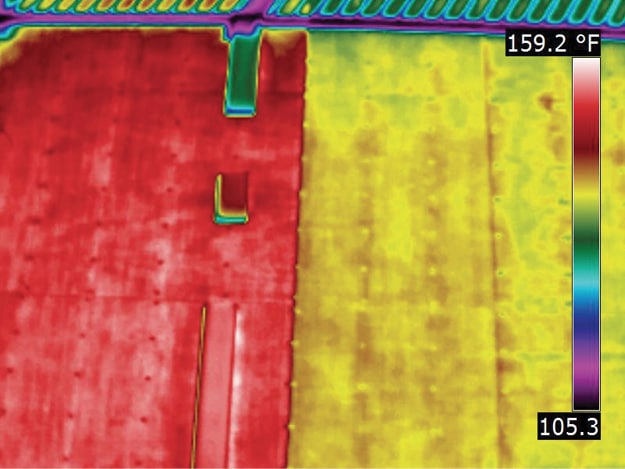

Once installed, the membrane reduces solar heat gain due to proprietary chemistry in the base plastics and inks. “Darker colors actually cool it,” says John Morley, a digital marketing specialist with the company, describing a paradoxical component of the product.

In a side-by-side comparison of IntelliDeck versus composite decking, IntelliDeck proves to be 20% cooler. This not only allows bare foot comfort, but also reduces heat near adjoining structures—the “heat island effect” that increases demand for mechanical air conditioning.

Green Facts

- About 3/4 of IntelliDeck is made from recycled manufacturing scrap from O’Sullivan Films’ other divisions that make interior flooring, auto interior products, health care materials, and flexible plastic windows.

- IntelliDeck’s manufacturing operations are zero-landfill facilities.

- Adhesives are made from water-based solvents the EPA deems acceptable and harmless.

Learn more about Intellideck.