Story at a glance:

- Architect Aaron Schiller reimagined a dilapidated 1870s carriage house in Brooklyn as his new home to test mass timber construction methods.

- Piggybacking onto a larger project for materials and partnering with local providers, Schiller Projects was able to streamline construction while minimizing its carbon footprint.

- Designed for longevity, the converted Brooklyn Mass Timber House has been nominated for an American Architects 2023 Building of the Year Award.

Aaron Schiller—founder and lead designer of the New York City-based architectural design firm Schiller Projects and a former carpenter—was looking for a residential project that would allow him to try his hand at mass timber construction.

“We were looking for clients who were interested in pushing the envelope on sustainability,” Schiller says. “We identified a need for a better quality of housing in terms of carbon footprint. It’s critical to the future of the country.”

Engineered for high strength, mass timber is lighter than steel or concrete and can replace both in load-bearing floors and walls. It’s also much lower in environmental impact than such carbon-intensive materials when constructed of sustainable lumber from managed forests.

Schiller eventually found the perfect project—an 1870s carriage house in Clinton Hill badly in need of renovation and primed for residential conversion—and the perfect clients: himself and his partner. “We bought it ourselves to design as a tentpole of what’s possible,” he says.

Gutted and Rebuilt

The living room of the Brooklyn Mass Timber House features floors recycled from the original timbers and integrated lighting from Stickbulb. Photo by Frank Frances

The building had seen better days. Formerly a limousine garage, the property’s front and rear facades were marred by previous renovations that bricked up windows and installed rollup doors. “It could have been mistaken for a meth lab,” Schiller says.

But the building didn’t share its sturdy, load-bearing masonry walls with any adjacent buildings—a rarity in the high-density, historic neighborhood. A gut rehab would present “a unique opportunity to add to an older structure,” Schiller says.

Long-range sustainability was central to the project. While commercial clients like to see LEED and other certifications, “that really is only half the point,” Schiller says. “You aren’t talking about the carbon footprint of the building and its construction. What drove us was the capacity to minimize the carbon footprint of the materials we were putting into the building.”

Sourced for Sustainability

- The home’s main bathroom offers modern tile from Inax Tile against custom wood cabinetry, designed by Schiller Projects. Photo by Frank Frances

- A view from inside the bedroom. Photo by Frank Frances

Since mass timber construction is relatively new to the United States, Schiller scoured the East Coast to find a larger project his future home might piggyback onto. A New England university was set to start construction on a mass timber dorm building, and he convinced the supplier to load a few extra engineered panels on its trucks.

“We called the manufacturer and said, ‘Hey, you’re already shipping all this timber to the Northeast. What if you added 5,000 more feet?’ Schiller says. “We showed up with a U-Haul truck, turned around, and delivered the raw material to our fabricator.”

Schiller added a rooftop master suite and terrace to the carriage house in converting it to a single-family residence. Photo by Frank Frances

Brooklyn-based Tri-Lox milled the lightweight, fire-resistant panels to specifications, fabricating them to within a sixteenth of an inch tolerance and transferring them from the factory floor to the job site. Material costs were a fraction of what Schiller would have paid for a standalone order.

Much of the home’s lighting was integrated into the mass timbers in manufacturing, creating the world’s first electrified laminated timber (ELT) installation. Schiller partnered with Stickbulb, a New York City-based sustainable lighting company, on the patent-pending system.

“When you make lighting integrated at the building level, you lose the pounds of aluminum in the fixture,” Schiller says. “It’s just LEDs and wire, so you’re able to get more control on the materials that come in and out of your site and limit its carbon footprint.”

An Intricate Installation

Glue-laminated Douglas fir forms the central stairwell that connects the three floors of the Brooklyn Mass Timber House. Photo by Frank Frances

Structural mass timbers were installed from flatbed trucks in just six days, marrying the new construction to walls that had settled and bowed since the 1870s. “We had to put something completely perfect coming out of a modern factory on top of this built structure from 150 years ago,” Schiller says. “There were some challenges.”

The studio also recycled components of the original structure, including the massive structural beams of old-growth North American timber that had sustained smoke and water damage over the years. “The old structure of the building is now the flooring of the completed building,” Schiller says. “We recycled the building inside the building.”

We recycled the building inside the building.

New components are designed to last 100 years or more without degradation. “We approached the project with the lifetime of the home in mind,” Schiller says. “Should the house need to be replaced at some point, the materials used can be repurposed without producing waste.”

The building’s facades now satisfy Landmarks Preservation Commission guidelines, showcasing redbrick construction, arched windows, and dark accents. The windows were fabricated a few blocks away, reducing the environmental impact of elements like a 15-foot wall of glass on the new third-floor master suite and terrace.

Bringing the Outside in

The carriage house’s former coal-ash pit was repurposed as an indoor garden with a Japanese maple. Photo by Frank Frances

A striking three-story staircase made of glue-laminated Douglas fir ascends through the center of the house, illuminated by large skylight. At the bottom, the building’s former coal ash pit has been repurposed as an indoor garden. “There’s a Japanese maple growing in the middle of the house, which has the additional benefit of cleaning the air,” Schiller says.

The home’s HVAC maximizes energy efficiency and adds to air quality. Schiller estimates that 45% of the square footage would have required drywall if he hadn’t used mass timber. “You’re creating a more organic and health-conscious environment,” he says. “If there are less VOCs in the atmosphere, the whole house is healthier—and the wood smells really good.

“The thing with this project is that it’s so constrained,” Schiller adds. “You’re in the middle of Brooklyn. You have a very well-defined lot. And then you have the opportunity to do something on the interior that defines it. The big moves we made—bringing in the timber, doing the stair, introducing the skylight—have all been richly rewarding.”

- The project restored the carriage house’s original redbrick facades and incorporates windows and doors from Mattison Millworks made locally in the Brooklyn Navy Yard. Photo by Frank Frances

- A stairway of glue-laminated Douglas fir descends through the center of the house, lit by a large skylight that forms part of a rooftop terrace. Photo by Frank Frances

Permitting caused a few delays because the house was only the third mass timber structure in New York City and the first residential property. “We had to educate people in the planning and fire departments about mass timber’s capacities versus its risks,” Schiller says. “A lot of people in this city aren’t used to working with this material.”

But the community “showed up” for the project to keep its construction impacts and carbon emissions low, he says. “The challenge of doing something new is that you have to bring a lot of folks with you. Fortunately the mission around climate impact gets a lot of people to the table, so people’s ears perk up and they say, ‘OK, this is different. We want to participate in this.’”

Project Details

Project: Brooklyn Mass Timber House

Location: Brooklyn, New York

Completion: 2023

Size: 3,050 square feet

Architects: Schiller Projects, Acheson Doyle Architects

Builder: Schiller Projects

Structural Engineer: Silman Associates

MEP/FP Engineer: PA Collins

Timber Fabricator: Bensonwood

Lighting Designer: Stickbulb/Schiller Projects/Loop Lighting

Landscape Architect: Brook Landscape

Interior Designer: Schiller Projects

Flooring: Tri-Lox

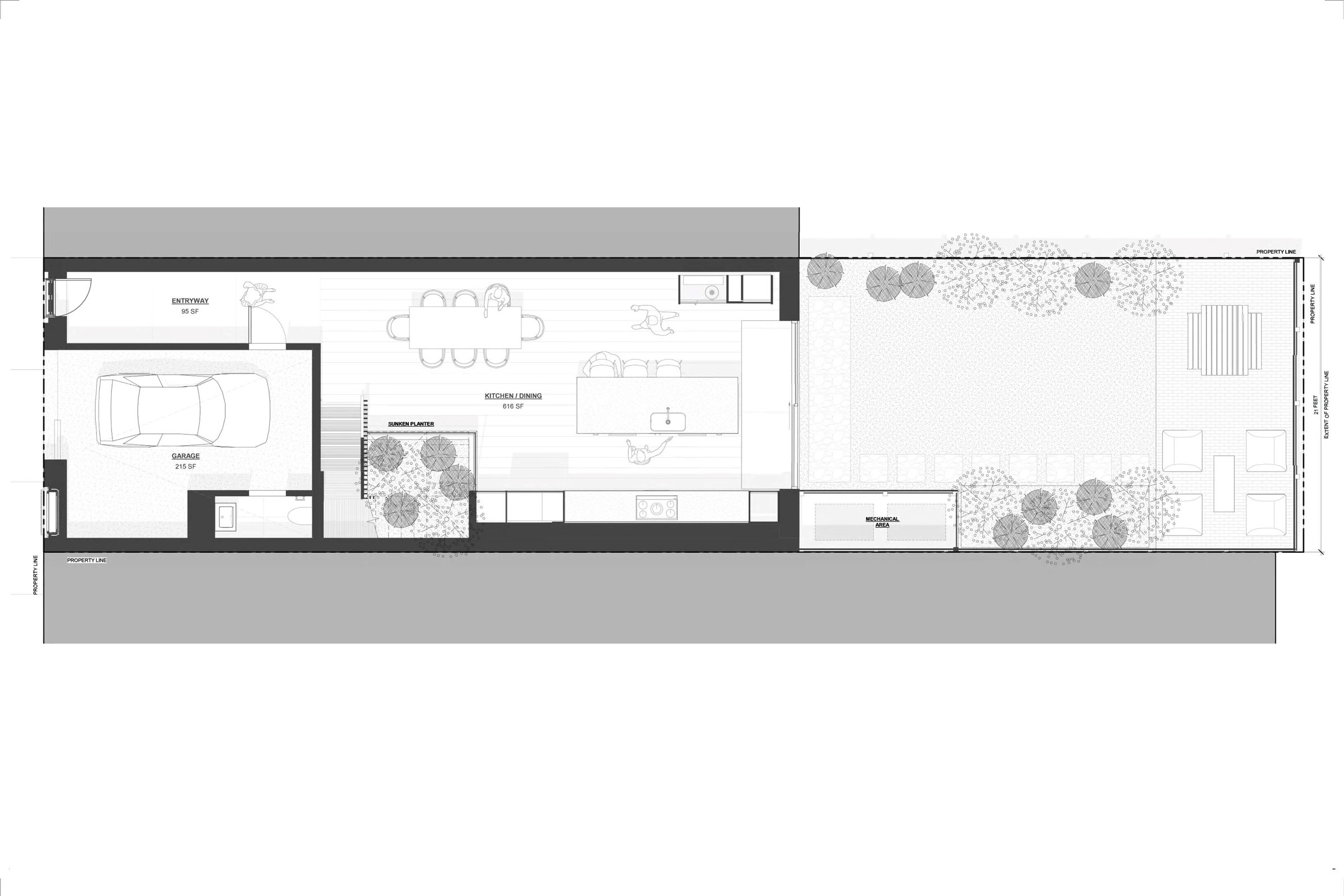

Drawing courtesy of Schiller Projects

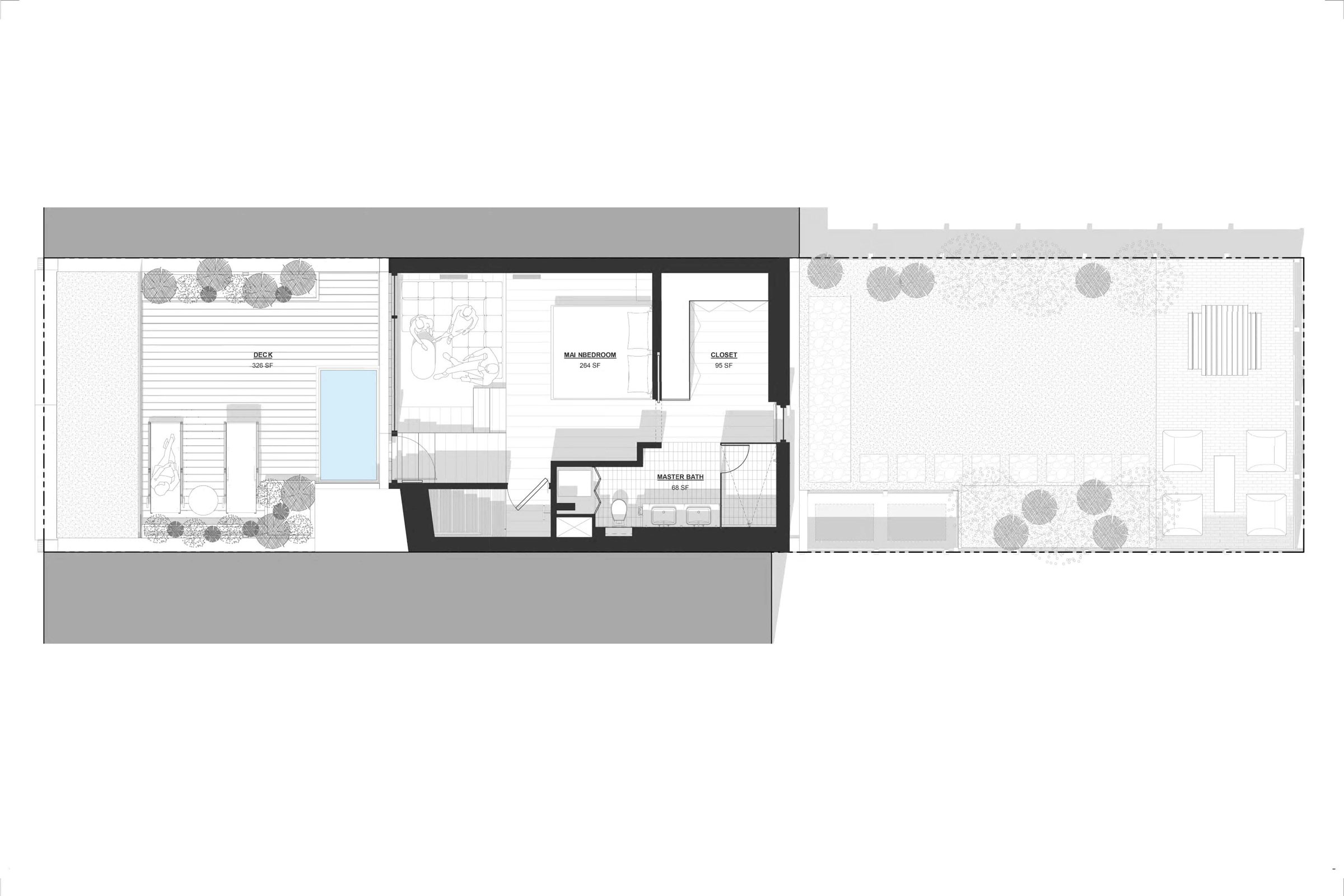

Drawing courtesy of Schiller Projects

Drawing courtesy of Schiller Projects