Story at a glance:

- Groundbreaking upgrades to materials like tile, metal, and foam are in demand. Improvements to products like insulated metal panels boost sustainability in projects.

- Innovative materials are also also working to protect buildings more effectively during extreme weather events like fires.

- Recycled and recyclable products are key to the materials revolution and a long, healthy future.

Today’s buildings must withstand increasing threats from extreme temperatures, floods, storms, and fires, all while minimizing environmental impacts. Material innovation can help meet these challenges and make spaces that are more safe, comfortable, and sustainable. Many familiar solutions are experiencing a material revolution.

“Over the years we’ve seen a shift in building design that looks for more resilient materials and sustainable designs that are also visually pleasing,” says Brian Ng, vice president of engineering at All Weather Insulated Panels (AWIP), a leading manufacturer of insulated metal panels with features like resistance to fire and thermal efficiency.

Evolving Materials

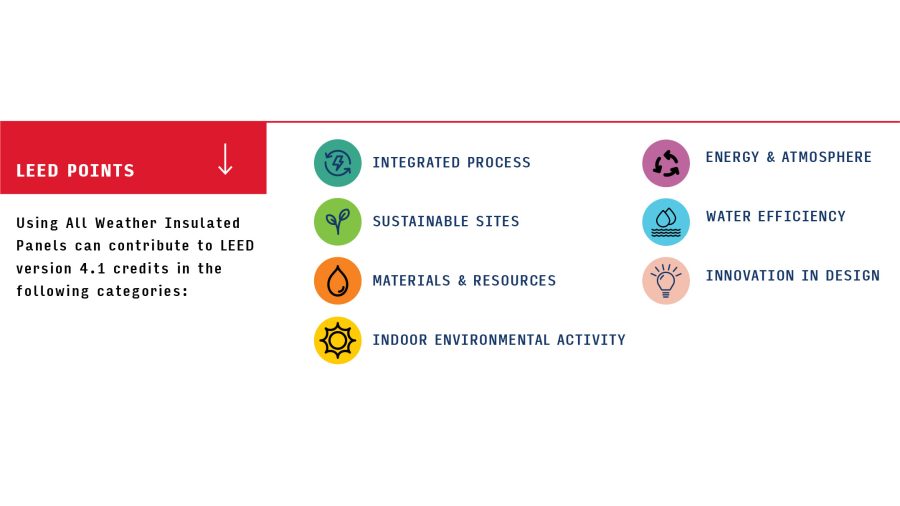

All Weather Insulated Panels supports qualifications and resources for sustainable building design that address WELL and LEED concerns, including rainwater harvesting, asbestos, vapor management, greenhouse gases, and metrics of energy cost. Photo by Greg Folkins, courtesy of All Weather Insulated Panels

Insulated metal panels are just one way manufacturers are demonstrating the potential of material innovation. Ng recalls how insulated metal panels were once used primarily for cold storage warehouses. Today they’ve evolved into a widely used material that can improve safety while meeting sustainability standards. “With these codes and standards in place, architects and building owners have naturally turned to insulated metal panels as a preferred solution,” Ng says.

InnovaCELL is AWIP’s new advanced, high-performance closed-cell foam—one of the materials that can deliver the highest R-values out there, Ng says. “By combining InnovaCELL technology with non-permeable steel facings, the foam is protected from the environment,” he says. These insulated metal panels stand up well to wear and harsh weather conditions for a long lifespan, while effectively preventing water penetration and providing added protection against extreme conditions like fires.

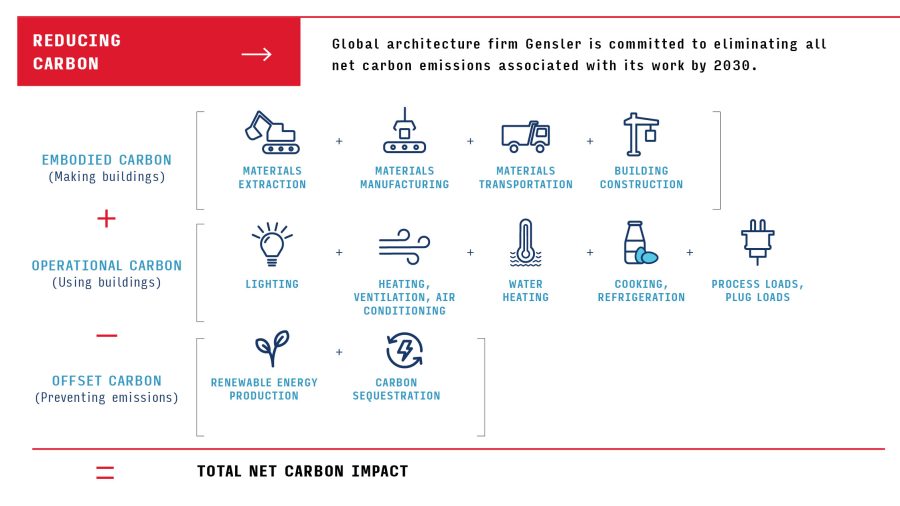

Global architecture firm Gensler is pushing the industry forward when it comes to choosing best-in-class building materials. “We really try to prioritize materials that reduce climate impacts first, improve health, and then also advance circularity,” says Gabe Hanson, North Central regional leader of climate action and sustainability at Gensler.

Gensler launched its new material standards, which anyone can access, in early 2024, starting with the most common high-impact product categories—from acoustic ceiling panels and carpet tiles to gypsum board, resilient flooring, and task chairs. “The goal was to create a tool for streamlining decision-making,” Hanson says. The firm continues to expand its Gensler Product Sustainability (GPS) Standards to include more categories, too.

Sustainability begins with material choice. Each GPS Standards product category includes criteria like being healthy and pollutant-free, sourced from rapidly renewable content, or recyclable. Hanson says certain items stand out for especially high sustainability impacts. “I think the most exciting innovations are those that transform the industry at scale,” he says.

Using fewer but higher quality materials can reduce the resource impact of new buildings. AWIP’s role includes “optimizing resource use but also lowering waste onsite and energy consumption, leading to more sustainable and efficient designs,” Ng says. Insulated metal panels with InnovaCELL technology are both durable and lightweight, which also speeds up the installation process, as it’s easier to handle a single component.

Improved Materials Make Safer Buildings

Photo by Bob Swanson and Finger Photography, courtesy of All Weather Insulated Panels

Ng says AWIP’s insulated metal panels use a tongue and groove design that conceals fasteners within the panel joint. “This not only improves aesthetics and weather resistance but also enhances the longevity of the fasteners by protecting them from the elements while maintaining the structural integrity of the entire system.”

The coming years will likely hold increased threats from weather and fire. Well-designed building solutions can more effectively keep water, hail, and dangerous debris from entering a building during a storm. Certain materials, like InnovaCELL, can help prevent the spread of fire. “It offers superior fire protection compared to some traditional foams, and when used in a specific assembly, it’s the first foam system to achieve a one-hour fire-rating,” Ng says. This means it’s certified to keep fire from spreading from one side of a wall to the other side within an hour.

InnovaCELL also improves on fire performance with its smoke-sensitive design. “It’s ideal for applications like pharmaceutical and food manufacturing or storage, where minimizing fire and smoke impact is critical,” Ng says. “Low smoke-generating materials can protect both the building’s interior and limit damage to its contents.”

A Circular Future

InnovaCELL incorporates recycled content within the foam in addition to the steel facings, helping to reduce landfill waste. “We’re upcycling reclaimed materials into our formulations to contribute to a more circular economy,” Ng says.

Hanson says circularity is gaining traction across the industry. “We are doing more assessments, such as product line assessments. And basically we’re seeing more scaling of recycled content and take-back programs.”

Still, leaders in the industry say more work needs to be done to improve sustainability and circularity in building materials. “I think advancing that circular economy in construction is going to be a key task for the entire industry,” Ng says.

How Companies are Making a Difference

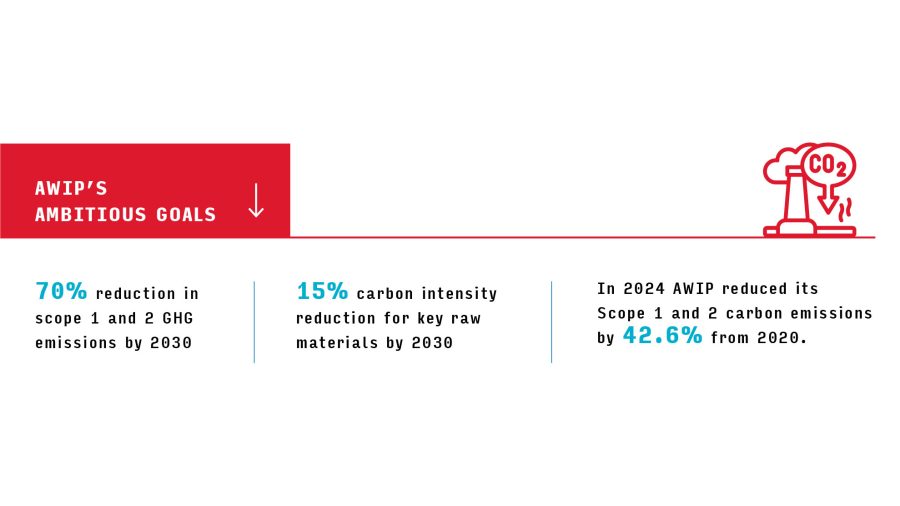

Graphic by Michael Esposito

Graphic by Michael Esposito

Graphic courtesy of Gensler