Story at a glance:

- Dan’s Place became the first project completed and opened under Cambridge’s new Affordable Housing Overlay zoning ordinance, which streamlines the process for developing more affordable housing.

- Finding value in the old and new, HMFH Architects proves renovating an existing historic building and designing a modernized sustainable project are not contradictory goals.

- From the airtight envelope and resilient flooring to the rooftop design and preserved trees, minimizing the project’s carbon footprint was considered in every detail.

According to the US Department of Housing and Urban Development’s 2024 Annual Homelessness Assessment Report to Congress, “the number of people experiencing homelessness on a single night in 2024 was the highest ever recorded.” More than 700,000 people were reported to be staying in emergency shelters, safe havens, transitional housing programs, or in unsheltered locations.

That’s why the need for affordable housing is greater than ever—and why HMFH Architects partnered with Cambridge Housing Authority (CHA) in Massachusetts to help meet those needs.

“Every community needs a certain minimal amount of affordable housing, and the Cambridge Housing Authority passed that by decades ago—and they are still building affordable housing,” says Lori Cowles, the HMFH Architects principal-in-charge for Dan’s Place, a CHA affordable housing project completed in March 2025.

History with a (Re)Purpose

Image courtesy of HMFH Architects

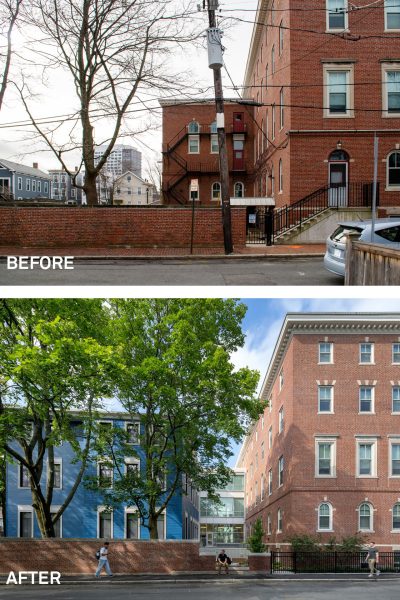

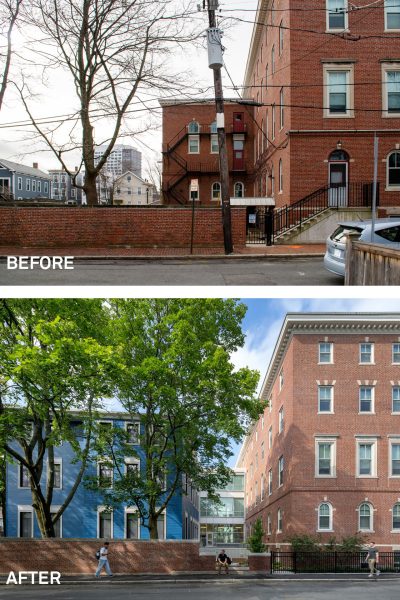

Built as a convent in 1907, the building at 116 Norfolk was converted to affordable housing in the 1970s before its most recent incarnation as Dan’s Place, named in honor of former CHA Executive Director Daniel J. Wuenschel.

The renewal and expansion of Dan’s Place was timely. Design work began as the country was navigating a pandemic and CHA was looking to modernize, moving away from the more communal style of single-room occupancy with its lack of privacy. As neighbors to 116 Norfolk, HMFH’s design team eagerly stepped in.

The site presented immediate challenges. Part of the original building was deemed useless and needed to be removed, raising the question of how HMFH could maximize that space with a new addition. The site had land, a rarity in Cambridge and especially this dense residential neighborhood, which meant HMFH was charged with preserving the lot’s natural landscape. And a new addition would need to be architecturally aligned with the original building, while the project as a whole needed to blend aesthetically with the neighbors.

“Renovating an existing historic building and doing a sustainable project, those two goals are not contradictory,” says Pete Rust, HMFH project manager. “We are always looking at renovations as an opportunity to minimize our carbon footprint because there’s already a lot of embodied carbon in an existing structure. If we’d torn down the original building and built completely new, we would have used a lot more energy.”

Despite its challenges Dan’s Place became the first project completed and opened under the city’s new Affordable Housing Overlay zoning ordinance, which streamlines the process for affordable housing development, lessens some of the more restrictive requirements, allows more building opportunities, and makes possible the complex financial formula it takes to build affordable housing.

Finding Value

Image courtesy of HMFH Architects

The neighboring homes and buildings are all done in wood frame, clapboard, and shingles, so HMFH retrofitted the existing building and utilized wood-frame construction for the addition to reduce the project’s embodied carbon. And while a brick base pays homage to the original building’s entirely brick exterior, the new addition’s fiber cement exterior replicates the look of those wooden clapboards and shingles. A cornice on the new addition also reflects the dentil cornice on the original building.

“They don’t look like the same building, they weren’t meant to, but when you stand back and look at the whole building and how it relates to the neighborhood, you can see the connection,” Cowles says.

It was a process for the architects to determine what had value and what needed to be replaced. A south-facing porch on the original building that previous residents loved ultimately had to be replaced. The ornate stairway, one the architects say they’d never be able to reconstruct, was salvaged and refurbished and is now a stunning feature of the renovated building. The existing front doors became interior doors. And some of the original wood flooring was reclaimed, refinished, and used as wood paneling in the community rooms.

“In terms of carbon footprint, reusing existing materials doesn’t make a huge difference, but it makes a symbolic difference,” Rust says. “I loved the opportunity to work with details I don’t typically get to, refurbishing original materials and working through unusual details. There’s value in retaining old buildings and using them as a jumping off point for new designs.”

Connecting with Nature

The Dan’s Place site presented immediate challenges. Part of the original building was deemed useless and needed to be removed, raising the question of how HMFH could maximize that space with a new addition. The site had land, a rarity in Cambridge and especially this dense residential neighborhood, which meant HMFH was charged with preserving the lot’s natural landscape. A new addition would need to be architecturally aligned with the original building, while the project as a whole needed to blend aesthetically with the neighbors. Photo by Ed Wonsek, courtesy of HMFH Architects

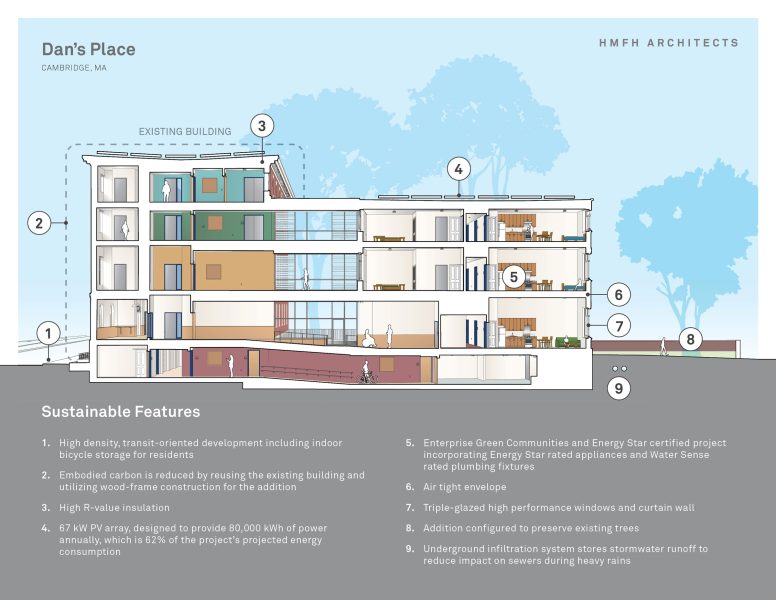

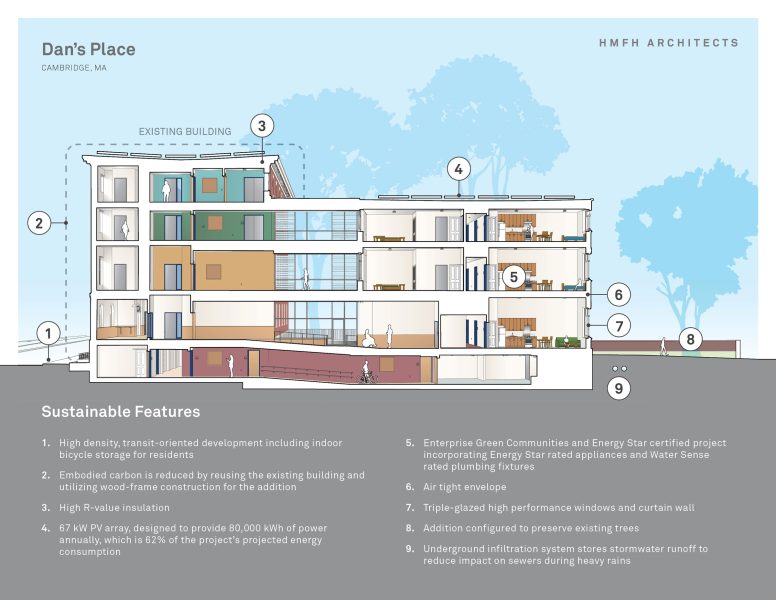

Because the project was on an urban site with proximity to amenities and public transportation, parking wasn’t necessary to the design. This allowed HMFH to provide resident amenities like indoor bicycle storage and, with the carefully sited addition, to preserve the trees within the coveted south-facing green space, creating outdoor spaces for residents to enjoy.

New life was also given to the cloister-type wall that had lined the perimeter of the property since it was a convent. The beautiful masonry was improved with a mosaic done by a local artist, as well as intimate pockets and bench areas for residents to enjoy, simultaneously providing privacy and connection to the neighborhood.

“Rather than saying, ‘Oh, this doesn’t really work,’ we asked ourselves: How can we improve on what’s here and make it last for the next 75 years?” Cowles says. “If, for example, we were going to jackhammer the foundation to run new piping, it needed to have minimal impact, but we also weren’t going to lay just one new little pipe—we were going to make the building better for the future.”

Another challenge HMFH’s team faced was finding space on the ground—or rather, under the ground—for an infiltration system with a series of chambers that capture and store stormwater runoff to reduce impact on sewers during significant weather events.

“Any place you dig on the site, you’re either going to have building foundation, tree roots, or infiltration system. There’s nothing left,” Rust says.

Even HMFH’s roof design took nature into consideration, maximizing open roof space by concentrating all mechanical, electrical, and plumbing equipment in certain areas to provide ample space for a PV solar array that generates more than half of the energy required to power the complex annually.

Designing for the Future

Sustainably conscious materials were used throughout the Dan’s Place project, including AVONITE Solid Surface countertops, which are LBC Red List–free, and FloorScore-certified Parterre engineered hardwood flooring. Photo by Ed Wonsek, courtesy of HMFH Architects

Architecturally, the project had unique programming—it was something CHA hadn’t done before, creating studio units for people coming out of homelessness while maximizing resident amenities, gathering and meeting spaces, and office spaces for support services, all of which you wouldn’t find in traditional affordable housing.

Between the original building’s 37 renovated units and the addition’s 25 new units, Dan’s Place now houses 62 residents in completely self-sufficient, move-in ready studio apartments featuring modern kitchens, private baths, high ceilings, tall windows, furniture, and household items.

The design of Dan’s Place followed passive house principles. HMFH installed triple-glazed, high-performance uPVC casement windows from INTUS Windows in the new addition, while retaining the existing windows in the original building. And with Cambridge’s typical northeastern climate—cold, dry winters and warm, humid summers, the windows also needed to be operable, allowing residents the flexibility to open their windows.

Creating an airtight exterior envelope was equally important but challenging because HMFH faced the ever-present question of how to balance renovating the old while designing the new.

“With new builds you can install a thick layer of insulation and you’re done. But when you’re dealing with an existing masonry building, you want to keep it aesthetically the same, but you can’t do that,” Rust says. HMFH’s solution was to install spray foam insulation on the inside face of the existing masonry wall, while in the addition, high-performance, high R-value ROCKWOOL Comfortbatt insulation was used for its LBC Red List–free and GREENGUARD Gold certifications.

Dan’s Place is a quiet space filled with natural light and clean air where interiors featuring an array of natural, sustainable, and durable materials create a cozy and domestic aesthetic that’s easy to maintain. The building is a modern take on affordable housing that prioritizes residents’ health, safety, and comfort.

“We want those in the industry to know it is possible to create decent housing for a relatively large number of people on a dense site while providing comforts like natural light and views,” Rust says.

Project Details

Project: Daniel J. Wuenschel Apartments (Dan’s Place)

Location: Cambridge, MA

Completion: March 2025

Size: 45,900 square feet

Architect: HMFH Architects

Engineer: GGD Consulting Engineers

Structural Engineer: RSE Associates

Contractor: Colantonio

Interior Designer: HMFH Architects

Civil Engineer: Samiotes Consultants

Landscape Architect: Crosby Schlessinger Smallridge

Specifications: Kalin Associates