A building’s facade is an investment, and one worth careful consideration. A favorite for design-build professionals, metal composite materials (MCM) adorn buildings across the world in a near-limitless selection of colors and patterns. At ALPOLIC, this lightweight, endlessly adaptable cladding is produced with high recycled content and manufactured with sustainability in mind. When compared to field-painted metal, our advanced coil-coating operations inhibit VOCs from entering the atmosphere, reduce waste, and provide longer-lasting, precision finishes.

We often receive inquiries about the types of paint used in manufacturing our MCM, specifically what the differences are between polyester and more expensive fluoropolymer finishes. While they do look similar, at least initially, the variances are more often seen in their performance over time. Understanding the chemical composition of each helps our customers make informed decisions about what is best for their specific projects.

Thermosets and Thermoplastics

Designed by KPB Architects and fabricated and installed by Northclad, this medical facility in Anchorage, AK is clad in ALPOLIC MCM, which calls to the lustrous surrounding mountain region. Photo courtesy of ALPOLIC

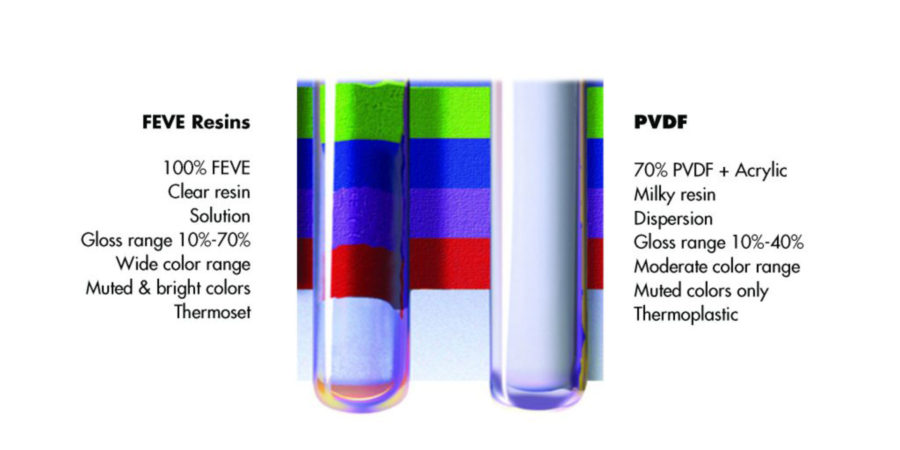

Two categories of paint used to coat MCM are thermoset and thermoplastic. Thermosets, like polyester and FEVE (LUMIFLON) paints, have clear resin bases allowing for a broad range of colors and glosses. Imagine adding red food coloring to a glass of water. The red color shows through easily, like in Kool-Aid. Thermoset paints, once cured, are not susceptible to pressure mottling (uneven or irregular gloss pattern on the painted surface of coil, typically heat or pressure-related). FEVE paints ensure exceptional color accuracy and provide the widest gloss ranges in the industry.

Thermoplastics, like the fluoropolymer PVDF (Kynar) paints, are a dispersion of 70% PVDF and 30% clear resin. The dispersion results in a milky appearance that does mute colors and limits the attainable gloss rating. Imagine adding the same red food coloring to a glass of milk. You will end up with pink milk but not bright red. Additionally, thermoplastics allow for the paint to soften with exposure to heat or pressure.

An easy analogy would be to equate thermoplastic paint to an ice cube and thermoset paint to an egg. When heated the ice cube becomes water, but if chilled again will be formed back into an ice cube. This process can be repeated often. A thermoset paint, in contrast, is like an egg. When the egg is heated it becomes a fried egg. When chilled it becomes a cold fried egg. It does not return to its original form.

Test Requirements

The second generation of fluoropolymer resins, FEVE, enables clear, bright colors in a wider gloss range. Image courtesy of ALPOLIC

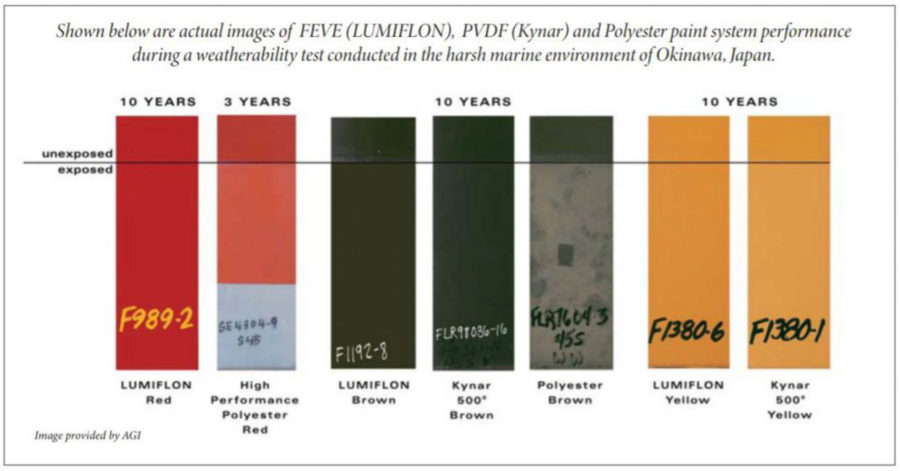

Polyester paints, in all their configurations such as Siliconized Polyester, Super Polyester, High-Performance Polyester, IJP, and Standard Polyester, have limited resistance to UV degradation. Though some perform better than others with UV exposure, no polyester paint reaches the highest finish standard of AAMA 2605. This specification requires, among other criteria, that in a 10-year South Florida exposure test, the color fastness is maintained in excess of 10 years exposure holding to a maximum variance of Delta E5. AAMA 2604 states that the finish will exceed five years of exposure within Delta E5. AAMA 2603 offers no assurance for the color fade.

Most polyester paints will meet AAMA 2603, and a few, with additives, may meet AAMA 2604, but only fluoropolymers such as FEVE (LUMIFLON) and PVDF (Kynar) will meet AAMA 2605.

Application Consideration

Weatherability testing showcases Lumiflon FEVE paint system’s consistent performance even in challenging coastal environments. Image courtesy of ALPOLIC

So, where the colors may begin as similar, polyester’s performance is greatly impacted by weather in a relatively short period of time. It will fade, peel, chalk much sooner than FEVE and to a much greater degree. For this reason, ALPOLIC recommends that all exterior applications should use FEVE for optimum exterior performance. Polyester paints may be used in interior applications where UV exposure is limited.

Fluoropolymer paints are inherently resistant to post-paint applications. They do not readily accept applications such as ink printing. This is also what makes these paint systems somewhat graffiti resistant. In contrast, most polyester paints can be printed upon, including with UV inkjet. When considering what the final application is, interior or exterior, printed or not, the paint type chosen can be an indicator of the success expected.