[Photo: Courtesy of Radioflyer]

One could say durability is the old-fashioned version of sustainability. Historically, household products were built to last a lifetime, if not several. If an item never falls apart and is disposed of, there is no need to manufacture a new one—avoiding the use of all the resources required to make it.

These days, few companies can claim more of a commitment to product durability than Radio Flyer, the toy manufacturer. Recently celebrating its 100th anniversary, Radio Flyer still makes its signature red wagon, along with tricycles, scooters, and other outdoor toys that continue to be built with the idea of passing them down from one generation to the next.

Robert Pasin, the company’s “chief wagon officer,” grew up observing his grandfather, an immigrant craftsman named Antonio Pasin, in his Chicago woodshop (the elder Pasin founded Radio Flyer in 1917) and recently expanded on that old-fashioned version of sustainability.

[Photo: Courtesy of Radioflyer]

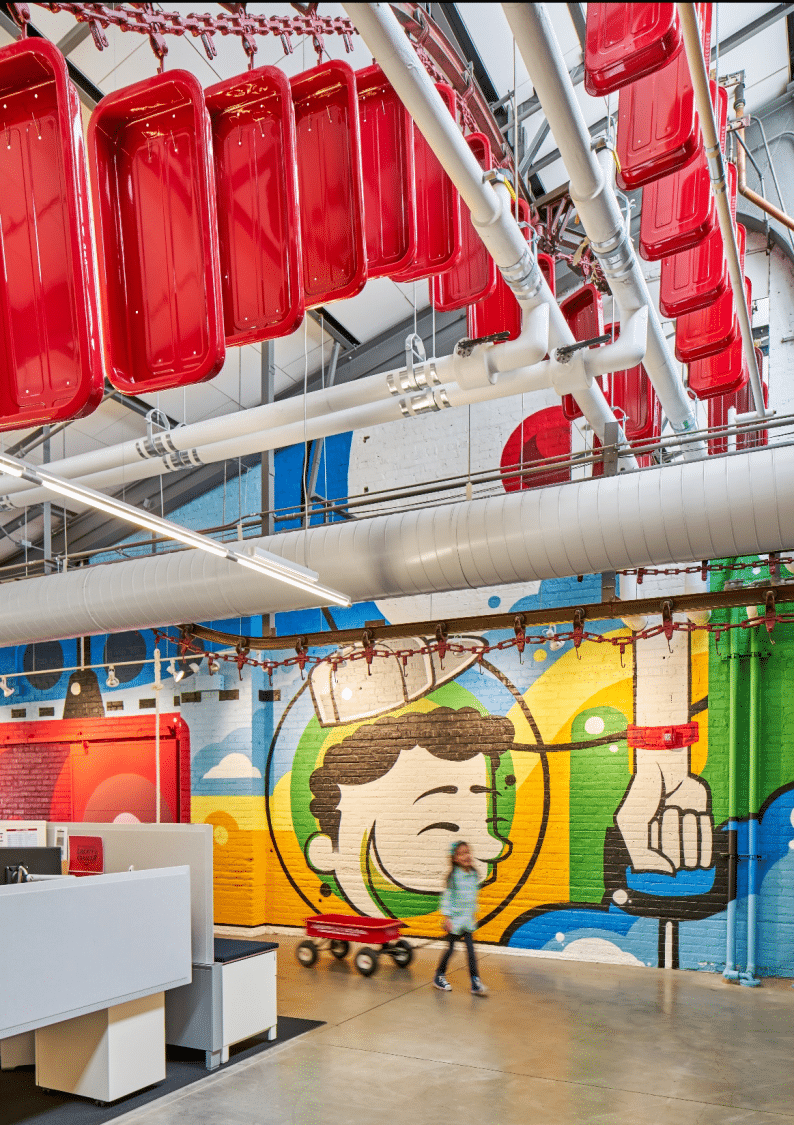

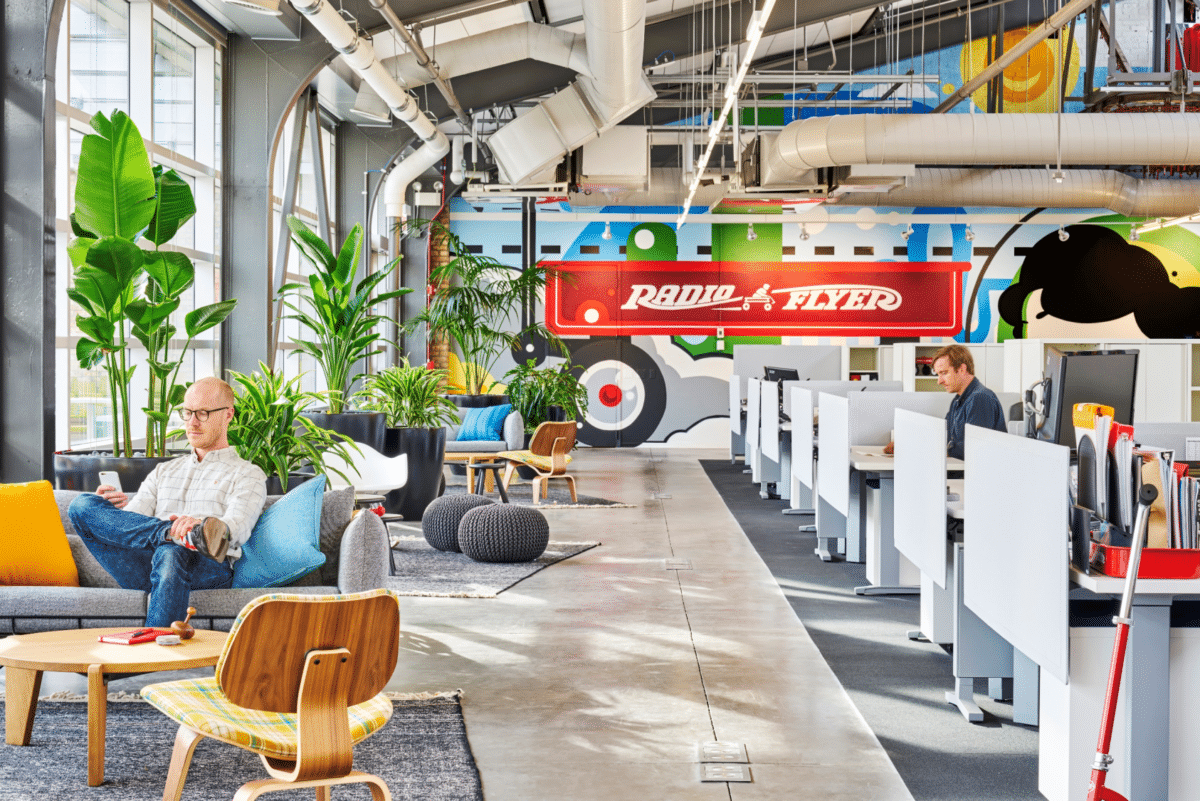

The company moved into its new LEED platinum headquarters in 2014—repurposing 70,000 square feet of its former manufacturing and warehouse space in Chicago—including a 30-foot glass facade for natural light and a backyard vegetable garden. They’re eliminating PVC from their toys, incorporating more environmentally friendly materials, and redesigning their product line to be lighter in weight, which cuts down dramatically on the fuel required to deliver each toy to the retail outlet or customer. They managed to shave three pounds off one of their wagons, resulting in a 15% decrease in greenhouse gas emissions.

The company even has a partnership with Elon Musk’s Tesla to produce a pint-sized toy Tesla to get your little ones thinking about alternative fuels at an early age. Just like the full-size version, it has a rechargeable battery that motors it down the driveway and a plug that allows your kid to blast their favorite tunes through the speakers. And don’t worry, a speed control feature limits the vehicle to three miles per hour for beginners or six miles per hour for “advanced” drivers.

Pasin, who is himself still a kid at heart, recently took the time to answer a few of our questions about the exciting changes at Radio Flyer.

[Photo: Courtesy of Radio Flyer]

gb&d: Did you grow up with an interest in the environment? Were there any formative experiences that might have sparked that?

Pasin: When I was young, my family had a farm in Wisconsin that my grandpa bought in the 1940s. Originally it was a dairy farm, but my dad, a conservationist, transformed it by ceasing farming and planting thousands of trees there. By doing this, the water quality of the lake went from being polluted from the fertilizers and manure to completely clean over the course of several years. Wildlife like wood ducks and fish returned in abundance. This made a big impact on me as a young person and I learned that it’s possible to reverse the effects of environmental damage.

gb&d: How did the Radio Flyer sustainability journey begin?

Pasin: I’ve always felt we should work to protect the environment. A key moment for me was at TED 2009 when Ray Anderson [the late founder of Interface and industrial ecology pioneer] gave his talk and really challenged businesses to do better on environmental issues.

gb&d: How does this reflect back on the 100-year history of the company?

Pasin: My grandpa was an Italian immigrant cabinet-maker, and two of his core values were to craft beautifully designed products that would last and to not waste anything. Those values are even more important now than they were a century ago. Our commitment to being a sustainable company is essential to laying the groundwork for another 100 years of business and innovating and creating timeless, quality products that will last generations.

[Photo: Courtesy of Radio Flyer]

gb&d: Radio Flyer is known for durable, long-lasting products, which is one key to sustainable manufacturing. Why do you think so many other toy makers have gone in a different direction?

Pasin: Radio Flyer depends so greatly on the outdoors—it’s where kids experience and make memories with our products. As a company, we feel we have a big stake in helping to preserve the environment for future generations. One of the bonuses of being a private company is that we’re able to look at the business with a different perspective and make decisions that are better for the company—and environment, in this case—in the long term. It’s hard to speak for others, but being passionate about the topic myself and having a dedicated workforce has helped us make an even greater commitment to sustainability at Radio Flyer.

gb&d: What other steps have you taken to reduce the environmental and human health impacts of your product line?

Pasin: We’ve taken several steps to improve the sustainability of our products. For example, the Big Flyer Sport, which we started producing in 2015, features a number of sustainability improvements. We removed PVC tread from the front wheel tires and created a design that weighs less. The product is also manufactured in Illinois, which reduces overall emissions associated with transport. In addition, we have a replacement parts program where we help people extend the life of their favorite Radio Flyer products. We provide parts for those looking to either refurbish a toy to pass it down or those simply replacing damaged or heavily used parts. In 2015 and 2016, Radio Flyer shipped more than 123,000 replacement parts—many of which were to restore existing products outside of their warranty period.

gb&d: What about operations?

Pasin: One way we work to reduce our carbon footprint is through logistics. As a SmartWay Transport Partner, Radio Flyer works with freight carriers that follow fuel-efficient best practices. This EPA program helps companies reduce greenhouse gas emissions and air pollution created by their freight providers.

[Photo: Courtesy of Radio Flyer]

gb&d: Tell us about your LEED Platinum headquarters.

Pasin: Our commitment as a brand is to inspire creativity and fun, the same spirit we infused into our 70,000-square-foot headquarters in Chicago. We repurposed the warehouse space and added green design solutions, including building cisterns to retain storm water and installing geothermal heating and cooling systems to reduce natural gas consumption up to 50%. We also added a 30-foot glass facade to provide natural light and a view of the backyard. It offers an inviting landscape with native plants, walking paths, a vegetable garden, and a picnic space we enjoy during the summer. We wanted the renovation to focus on improving overall employee health and productivity, so we also added exercise and wellness rooms and sit/stand desks in the communal work area.

gb&d: How do you track the success of your sustainability efforts?

Pasin: One of the most important tools we use to track the success of our efforts is scorecards. For example, when we look at our sustainable materials goal, our current product line is 98.5% PVC-free products, but we are aiming to get to 99% by the end of the year. We’ve also set an aspiration for the future to reach 100% PVC-free. From our scorecard work, we are developing a set of sustainability criteria covering GHG emissions, recycled content, sustainable and safe materials, ease of disassembly, and social compliance. Our aspiration is for all of our products to meet target thresholds within each of these areas. In 2016, we set a goal for 10% of our products to meet the sustainability criteria, and all departments work together to pursue positive changes toward this goal.

gb&d: What about social impacts?

Pasin: Our mission is to bring smiles and warm memories to families all over the world, and we work diligently across the company to ensure these positive impacts. We work to make a difference as a company in our community through paid time off to volunteer, donating products to children’s hospitals through our partnership with the Starlight Foundation, and building trees for every wagon sold online in partnership with the Arbor Day Foundation. We also strive to work with ethical manufacturing partners overseas; 99.9% of our overseas volume comes from suppliers who have received the “ICP Seal of Compliance,” and we continue to work toward our goal of 100% compliance. This seal means the facilities have been audited and met the standards of the International Council of Toy Industries ethical manufacturing program called the ICTI CARE Process. The seal ensures these facilities have responsible practices in the areas of health and safety, child and forced labor, working hours and wages, discrimination and disciplinary practices, and social benefits.

[Photo: Courtesy of Radio Flyer]

gb&d: Who are the Eco Flyers?

Pasin: Eco Flyers are employees passionate about the environment who lead our sustainability efforts at Radio Flyer by helping to identify opportunities for employees to reduce their carbon footprint and minimize waste. We recently introduced a new composting initiative, bringing our headquarters one step closer to becoming a zero-waste facility. The finished composted items provide our garden with rich fertilizer.

gb&d: You also have a SMILE Squad and a wellness team. How do these relate to the company’s mission?

Pasin: All of our employee teams at Radio Flyer work to ensure we have a presence as a company in our local community. Our Smile Squad supports social responsibility and coordinates various community service opportunities throughout the year, including building playgrounds for schools in need. Our wellness team works to encourage a healthy lifestyle through nutritional guidance and motivation. Every year the team coordinates a summer fitness challenge to help offer new and exciting ways to get exercise in, as well as team-based incentives. They also worked with our Eco Flyers following the renovation to plant gardens in our backyard, which employees have access to regularly to harvest vegetables and other plants for lunch or dinner.

gb&d: What are the top priorities for the toy industry at large to become sustainable?

Pasin: There are a lot of ways the industry can contribute to making toy-making a more sustainable business. The top priorities that stick out in my mind are continuing to ensure durable products, safe materials, and reduced transport impacts.