Story at a glance:

- ECONYL nylon, created by Aquafil, is made out of waste that’s been rescued from landfills and oceans around the world.

- It performs exactly the same as standard nylon, and it can be recycled, reimagined, and remolded again and again.

- ECONYL applications run the gamut from designer rugs and apparel to furniture and even car interiors.

As modern designers make increasingly sustainable choices, regenerated nylon has become a hot topic. ECONYL® nylon is made entirely from waste, is 100% recyclable, and offers up to a 90% reduction in global warming potential compared to standard nylon. It’s an inspirational process that transforms a historical wasteful material into a closed-loop system.

“There are endless possibilities when it comes to designing with ECONYL nylon,” says Ian Burt, director of sales and marketing for Aquafil USA. “Nylon is a super versatile material, and the fact that it’s regenerated means we’re not consuming new resources to design new products.”

What is ECONYL?

ECONYL regenerated nylon is used in beautiful rugs from Interface, Delos, and FLOR (seen here), among many others. Photo courtesy of FLOR

In 2011 Giulio Bonazzi, the second generation leader of the family-owned Aquafil, had the idea to combine waste reduction with the production of nylon. He called it ECONYL—a nylon 6 derived fully from regenerated waste materials. Since then ECONYL nylon has been featured everywhere from Speedo swimsuits to Stella McCartney designer bags. But it’s also used widely in interiors—from the finest rugs to award-winning chairs to colorful tabletops made from ECONYL polymers and recycled fishing nets.

“It really started as a commercial carpet conversation, but now it’s in so many other places,” Burt says.

“Flooring, apparel, furniture, lighting, 3D printing—there seem to be new applications for ECONYL nylon every day. We are partnering with our customers to really push the bounds with ECONYL nylon and morph the material to fit their needs,” Burt says.

What is Regenerated Nylon?

Photo courtesy of Aquafil

The ECONYL Regeneration System begins when waste from carpet flooring, fishing nets, fabric scraps, and industrial plastic is rescued, sorted, and cleaned to recover all of the nylon possible. It’s an intensive process that is hugely beneficial to the environment. In fact, for every 10,000 tons of ECONYL raw material, 70,000 barrels of crude oil are saved and 65,100 tons of CO2 equivalent emissions are avoided.

ECONYL nylon is essentially made in four steps. After the waste is rescued, the regeneration and purification process takes place, recycling the nylon waste back to its original purity. Then the nylon is reimagined into a wide breadth of new products. Performance-wise ECONYL nylon is exactly the same as standard nylon, as it’s regenerated back to its original form. “It is identical to a nylon sourced from oil without the lofty environmental impact,” Burt says.

Fashion brands and carpet producers both widely use ECONYL nylon to create exciting new products. An added bonus is that this nylon has the potential to be recycled infinitely, without ever losing its quality.

The color will also stay vibrant, as it’s bleach- and fade-resistant. The ECONYL Global Collection comes in 176 colors. “Our colors are bright and bold, and our options empower designers to create beautiful designs without having to use new resources,” Burt says.

Why Specify ECONYL Nylon?

With ECONYL nylon designers are empowered to create new collections and styles over and over again without using new resources. Photo courtesy of Aquafil

The materials you specify in a product or project have a huge impact on their recyclability at the end of its life. Designers can influence up to 90% of a product environmental footprint with their early design decisions by choosing sustainable ingredients that are recycled and recyclable like ECONYL nylon. According to the Ellen MacArthur Foundation, by applying circular strategies to five of the most common materials, by applying circular strategies to five of the most common materials in the economy—cement, aluminum, steel, plastic, and food—we can eliminate 9.3 billion tonnes of carbon dioxide by 2050.

Specifying products made with ECONYL nylon can also help projects earn LEED credits. It contributes toward earning LEED credits covering categories like Integrative Process, Indoor Environmental Quality, Materials and Resources, and Innovation. It’s made from 100% waste and is 100% recyclable, depending on the product. “It lowers the impact of that material all the way around,” Burt says. It’s also Cradle to Cradle-certified and EPD-verified.

While interest in ECONYL nylon was largely driven by carpet manufacturers early on, Aquafil is now seeing even wider interest—including in the automotive market. ECONYL nylon helps meet the durability and safety standards that top global car manufacturers demand.

Designing with the end in mind empowers designers to create sound products that have a solution at the end of their lives.

“The conversation is morphing. It’s not just about using recycled materials. It’s how do we actually design better products that can be reclaimed and recycled at the end of its life?” Burt says. “Designing with the end in mind empowers designers to create sound products that have a solution at the end of their lives. This mindset shift is happening now, which is super powerful.”

That ability to increasingly reimagine products with the end in mind is inspiring to say the least. “How can something be designed properly to facilitate the best end of life use?” Burt says.

Applications of Regenerated Nylon

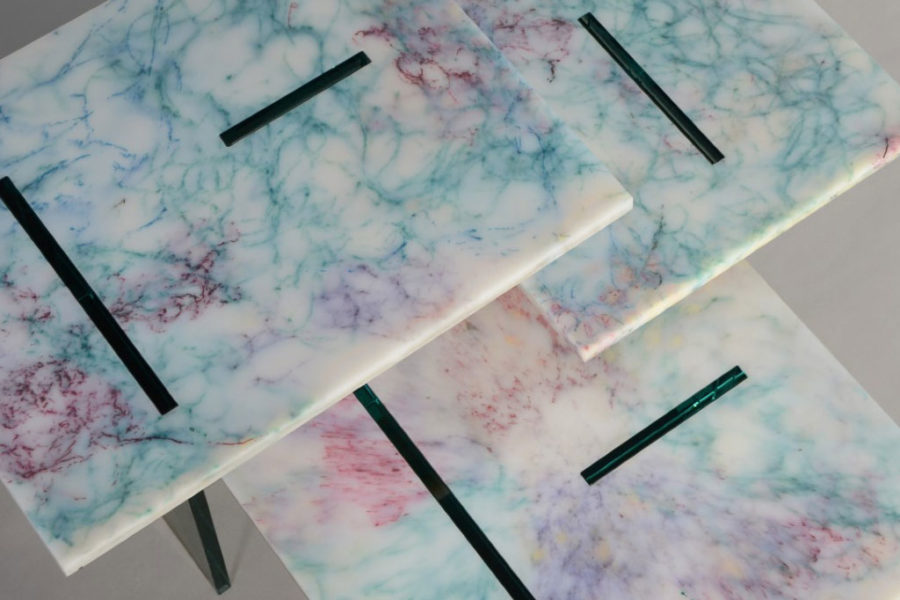

The tabletops of Alcarol prototypes are made of colorful fishing nets from the ocean melted together with ECONYL polymer, produced through an innovative and sustainable chemical process that regenerates nylon waste including fishing and aquaculture. Photo courtesy of alcarol

You can use regenerated nylon anywhere you’d use regular nylon. “Because we take it back to its raw material, ECONYL nylon is chemically the exact same as standard nylon,” Burt says. Carpet, apparel, backpacks—it can be used virtually anywhere. “The question is—how can we transform the design industry to reassess the traditional design process.”

Even chairs can be made of regenerated nylon. One great example is the noho move chair, which previously won NeoCon’s Best of NeoCon Gold and Sustainability awards. Made with ECONYL regenerated nylon, the mesh seat provides four-way flex and form-fitting support that cradles your body. Its “forward-tilt” and “recline-flex” combine for fluid motion and ergonomic support, intuitively responding to every activity and posture, eliminating pressure points, and improving circulation. It’s perfect for relaxing or even working from home.

Interface is one of many interior brands that works widely with ECONYL nylon. Its Human Nature flooring collection includes five different textures in skinny planks evoking the warmth and comfort of biophilic design. You’ll also find ECONYL nylon in Tom Dixon products, Porsche, Prada, Pottery Barn, FLOR, and countless other major brands across markets.

Also inspiring are the marbled alcarol tables that make up the OCEAN NETWORKS collection. These are made from colorful fishing nets collected from aquaculture farms melted with ECONYL® polymers. Through the transparency and reflections of the glass at different heights, the multicolor fishing nets of the tabletops appear to float. alcarol loves ECONYL nylon for its look and its reuse—as there’s no difference from using a standard nylon made with oil, but it can be recycled infinitely without any loss in quality.

“With ECONYL we can design in the ease of recyclability before we ever make the product,” Burt says. “The possibilities are endless.”