Story at a glance:

- ASC Steel Deck is committed to making it easier for the design community to confidently design and specify steel deck products for LEED projects.

- Steel deck products can help earn LEED points in the Material and Resources and Indoor Environmental Quality categories.

Green certification programs like USGBC’s LEED rating system have transformed how buildings are designed and built. Across many building product categories, manufacturers have been proactive in their green journey and understand they are essential partners in contributing to healthy and environmentally responsible buildings.

ASC Steel Deck, a leading West Coast steel deck manufacturer for more than 50 years, has been at the forefront of this green transformational journey. Through initiatives like implementing continuous improvement processes to minimizing waste, its recycling process, supply chain optimization, and providing transparency disclosures, ASC Steel Deck passionately continues down its green path.

USGBC’s LEED program is one of the world’s most recognized green rating systems. As an industry partner, ASC Steel Deck is committed to making it easier for the design community to confidently design and specify steel deck products for LEED projects. We have completed an assessment of how steel deck products may contribute to projects designed to the most recent LEED v4.1 standards. Below is a summary of those findings, as well as how ASC Steel Deck may contribute toward points for LEED projects.

LEED Rating System Categories

Photo courtesy of ASC Steel Deck

The LEED Rating System is made up of seven categories, listed below. The Material and Resources and Indoor Environmental Quality categories are the two areas where steel deck products may contribute toward LEED points.

- Sustainable Sites

- Water Efficiency

- Energy and Atmosphere

- Material and Resources

- Indoor Environmental Quality

- Innovation

- Regional Priority

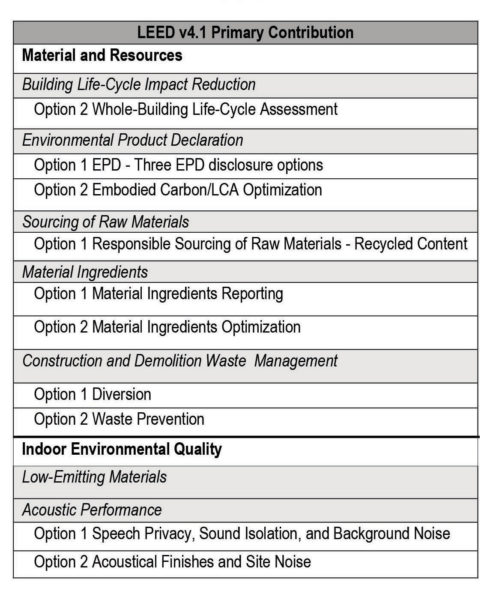

At a high level, Table 1 lists the two categories within USGBC’s LEED rating system where a steel deck manufacturer may contribute primary credits due to a green performance attribute and the manufacturer’s ability to provide transparency disclosure documents called out in the most recent updates to LEED v4.1.

Here we break down each of the two categories, although the actual point contribution to a project will vary based on the type of project and the design. It is important to note that project teams currently pursuing LEED v4 may have the opportunity to apply the LEED v4.1 credits and prerequisites in place of the LEED v4 language, allowing teams to take advantage of credits that may be more accessible for their project.

Table 1. Two main categories for possible point contributions toward LEED v4.1 projects. Table courtesy of ASC Steel Deck

Materials and Resources

The Materials and Resources catetory focuses on minimizing the environmental impact due to the entire product manufacturing process, from sourcing materials through manufacturing the end-use product installed on a building to the end of the product’s life use. When LEED v4 launched, the Materials and Resources category accounted for 11% of the contributions from all the categories, which has not changed with the most recent LEED 4.1 updates.

Within the Materials and Resources category, there are five credit areas where steel deck products may contribute toward LEED points. Under LEED v4.1 USGBC made amendments to each of these credit areas. Here is what you need to know:

- Building Life-Cycle Impact Reduction

- Environmental Product Declaration (EPD)

- Sourcing of Raw Materials

- Material Ingredients

- Construction and Demolition Waste Management

Building Life-Cycle Impact Reduction

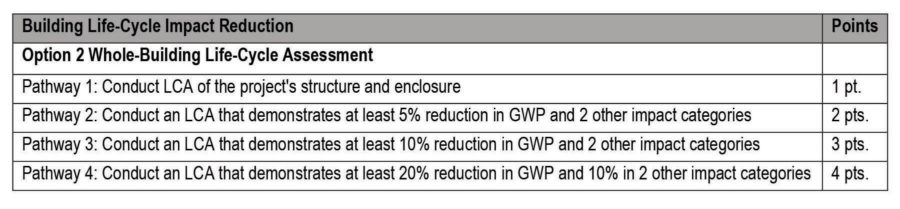

The intent of the Building Life-Cycle Impact Reduction credit is to include a greater focus on reducing embodied carbon of building structures and enclosures. Option 2 Whole-Building Life Cycle Assessment (LCA) applies to new construction and a cradle-to-grave LCA of the project’s structure and enclosure, with one of four possible pathways to earn points.

Steel deck roof and floor panels are considered part of a building’s structure and enclosure. A steel deck manufacturer with an EPD can contribute towards one point because an EPD can be used to conduct the LCA. ASC Steel Deck can contribute toward this credit as we have an EPD and have the proud distinction of being the first west coast steel deck manufacturer to offer a Product-Specific Type III EPD.

Table 2 summarizes the four pathways of Building Life-Cycle Impact Reduction Option 2. For Pathway 2 through Pathway 4, the project team must demonstrate a reduction in Global Warming Potential (GWP) and two other impact categories.

Table 2. Building life-cycle impact reduction. Table courtesy of ASC Steel Deck

Impact categories for reduction are:

- Global warming potential (greenhouse gases), in kg CO2e

- Depletion of the stratospheric ozone layer, in kg CFC-11

- Acidification of land and water sources, in moles H+ or kg SO2e

- Eutrophication, in kg nitrogen or kg phosphate eq

- Formation of tropospheric ozone, in kg NOx, kg O3 eq, or kg ethene

- Depletion of nonrenewable energy resources, in MJ using CML/depletion of fossil fuels in TRACI

Environmental Product Declaration

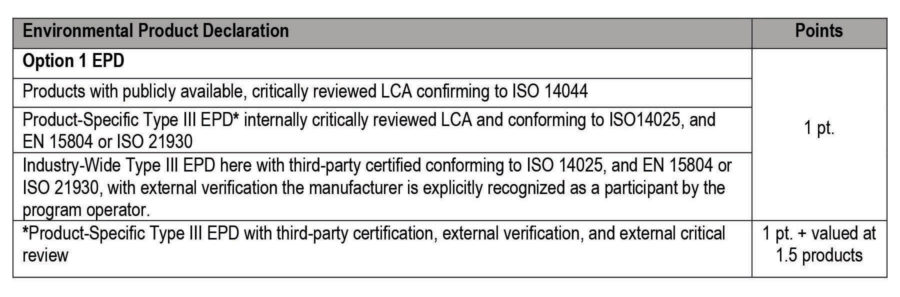

The intent of the Environmental Product Declaration credit is to encourage the use of products and materials with available life cycle information and have environmentally, economically, and socially preferable life cycle impacts. Under LEED v4.1 USGBC made amendments to the EPD credit to simplify the selection of products with LCA data and increase the ability to select optimized products.

Under Option 1 EPD: The project team must use at least 20 permanently installed products sourced from at least five manufacturers that meet one of the disclosure criteria listed below and may contribute toward a point contribution. There is an opportunity for a product to be valued at 1.5 products with a compliant disclosure. See Table 3 for Environmental Product Declaration Option 1 point contribution.

Table 3. Environmental product declaration, option 1. Table courtesy of ASC Steel Deck

ASC Steel Deck can contribute a point, and its products can be valued as 1.5 products as we have a Product-Specific Type III EPD with third-party certification, external verification, and external critical review.

It is important to note that EPDs are for disclosure purposes only. They do not necessarily mean a product meets an environmental performance standard. Moreover, EPDs may not always be comparable. It’s important to consider differences in geographic scope, product category rules, modeling assumptions, the type of LCA software used, and the time period(s) covered by the data.

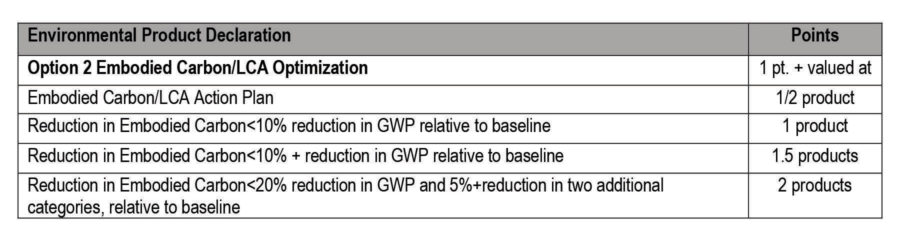

Under Option 2 Embodied Carbon/LCA Optimization, Table 4: The project team must use products that have a compliant embodied carbon optimization report or action plan separate from the LCA or EPD. The project team must use at least five permanently installed products sourced from at least three manufacturers that meets a compliant disclosure listed below may contribute toward a point contribution. Products are valued according to Table 4.

Table 4. Environmental product declaration, option 2. Table courtesy of ASC Steel Deck

Sourcing of Raw Materials

The intent of the Sourcing of Raw Materials credit is to encourage the use of products and materials with available life cycle information and have environmentally, economically, and socially preferable life cycle impacts.

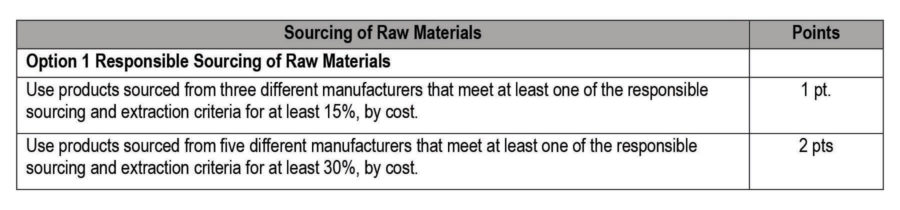

Under LEED v4.1, the area in which a steel deck manufacturer may contribute points falls under the Responsible Sourcing of Raw Materials criteria, which lists several responsible sourcing and extraction options. The Recycled Content criteria would apply to steel deck products. It is essential to note in LEED v4.1, USGBC removed the 30% limitation on structural and enclosure materials. ASC Steel Deck can provide a recycled content document for this credit. Products are valued according to Table 5.

Table 5. Sourcing of raw materials, option 1. Table courtesy of ASC Steel Deck

Steel deck products are factory-produced on a made-to-order basis, resulting in less scrap at the job site. Moreover, one of steel deck products’ important green performance attributes is its recyclability and contribution to a circular economy. According to the American Institute of Steel Construction, the inherent long-term durability of structural steel will essentially last the life span of the building. Throughout the life span of the steel deck product, the performance of the product remains consistent, and at the end of its life use, steel deck products are 100% recyclable.

Material Ingredients

The intent of the Material Ingredients credit is to reward project teams for selecting products with an inventory of chemical ingredients in the product using an acceptable methodology and selecting verified products to minimize the use of harmful substances. Under LEED v4.1, USGBC made amendments to the category, which is explained below.

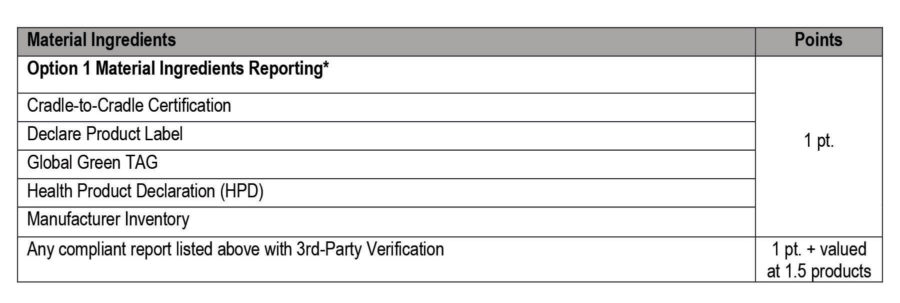

Under Option 1 Material Ingredients Reporting, Table 6: The project team must use at least 20 permanently installed products sourced from at least five manufacturers that use any of the programs below to demonstrate the chemical inventory of the product to at least 0.1% (1,000 parts per million). A point contribution may apply toward the project. There is an opportunity for a product to be valued at 1.5 products with a compliant report.

Table 6. Material ingredients, option 1. Table courtesy of ASC Steel Deck

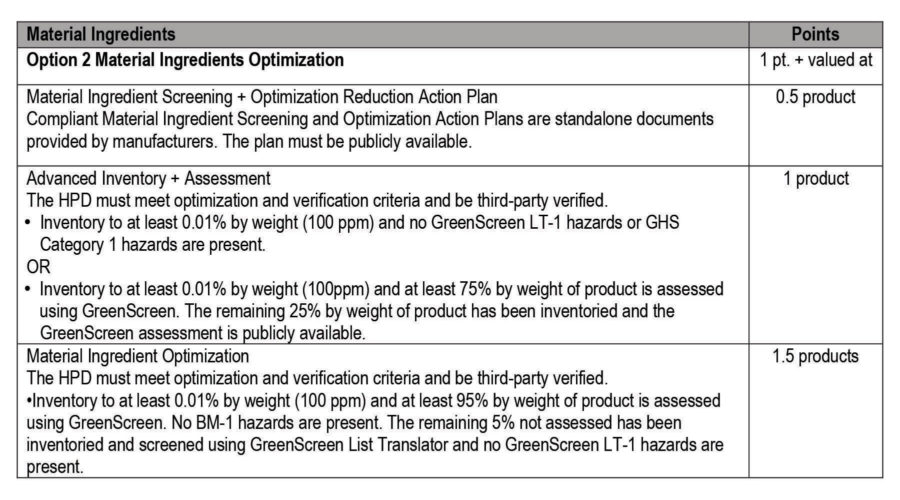

Under Option 2 Material Ingredients Optimization, Table 7: The project team must use at least five permanently installed products sourced from at least three manufacturers with a compliant material ingredient optimization report or action plan. Report type and criteria are outlined below.

Table 7. Material ingredients, option 2. Table courtesy of ASC Steel Deck

ASC Steel Deck has the proud distinction of being able to contribute toward the Material Ingredients credit for both Option 1 and Option 2. Under Option 1 ASC Steel Deck can provide a third-party verified HPD that can contribute toward a point and have our steel deck product valued at 1.5 products. Under Option 2 ASC Steel Deck can offer a third-party verified LBC Red List Free Declare label that meets the Advance Inventory + Assessment criteria. We can contribute toward a point with a one-product valuation.

Construction and Demolition Waste Management

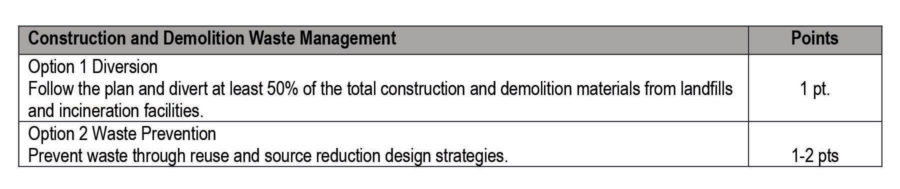

The intent of the Construction and Demolition Waste Management credit is to reduce construction and demolition waste disposed of in landfills and incineration facilities. The project team must develop and implement a construction and demolition waste management plan that identifies strategies to reduce waste generation, establish waste diversion goals for the project, and describe the diversion strategies and where the materials will be taken.

There are two options where a steel deck manufacturer may contribute toward points for this credit. In Table 8, under Option 1, steel deck products are manufactured on a “cut-to-size” bases at the manufacture’s plant, minimizing waste at the jobsite. Any remaining steel deck panels may be incorporated into a waste diversion recycling process In Option 2, the way in which the steel deck products are manufactured supports a source reduction design strategy. ASC Steel Deck provides a Construction and Demolition Waste document for this credit.

Table 8. Construction and demolition waste management. Table courtesy of ASC Steel Deck

Indoor Environmental Quality Category

The Indoor Environmental Quality category focuses on indoor air quality, lighting, thermal condition, and acoustics and their effects on the occupants. Within this category there are two credit areas where steel deck products may contribute toward LEED v4.1 points.

• Low-Emitting Materials

• Acoustic Performance

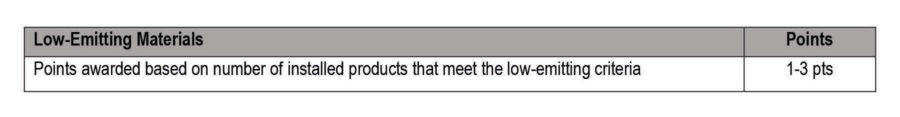

Low-Emitting Materials

The intent of the Low-Emitting Materials credit is to reduce concentrations of chemical contaminants that can damage air quality, the environment, and human health. This credit applies to materials on the building interior that meet the low-emitting criteria, Table 9.

Steel deck products are made using hot-dipped galvanized coated steel material, which is an inherently non-emitting source. Moreover, optional factory-applied primer is applied on steel deck products when used in an exposed ceiling or acoustical application. You will need to confirm with the manufacturer if the optional factory-applied primer used on the final product is also an inherently non-emitting source. ASC Steel Deck’s product offer with the factory applied Prime Shield® primer meets the low-emitting criteria included in this credit.

Table 9. Low-emitting materials. Table courtesy of ASC Steel Deck

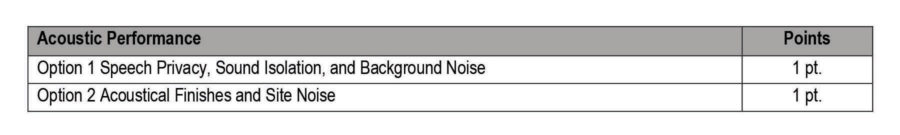

Acoustic Performance

The intent of the Acoustic Performance credit is to provide workspaces and classrooms that promote the occupants’ well-being, productivity, and communications through effective acoustic design, Table 10.

Table 10. Acoustic performance. Table courtesy of ASC Steel Deck

Steel deck acoustical products may provide the same noise reduction performance as standard mineral fiber, fiberglass, and other ceiling tile systems. Steel deck manufacturers may offer products used in acoustic applications with testing for sound adsorption characteristics of assemblies. You will need to confirm with the manufacturer how their acoustical product offer may apply.

ASC Steel Deck’s Acustadek® products have been tested for sound absorption characteristics of assemblies. Most Acustadek® profile and perforation types meet a minimum threshold of 0.60 Noise Reduction Coefficient (NRC) or greater. ASC Steek Deck provides sound absorption data documentation for Acustadek® products.

Steel Deck and Sustainability

ASC Steel Deck has available documentation for each of the credits listed below. You can access supporting documentation for each LEED category by following the links.

Material and Resources

Building Life-Cycle Impact Reduction

Option 2 Whole-Building Life-Cycle Assessment

Environmental Product Declaration

Option 1 EPD – Product-Specific Type III EPD

Sourcing of Raw Materials

Option 1 Responsible Sourcing of Raw Materials – Recycled Content

Material Ingredients

Option 1 Material Ingredients Reporting

Option 2 Material Ingredients Optimization

Construction and Demolition Waste Management

Option 1 Diversion

Option 2 Waste Prevention

Indoor Environmental Quality

Low-Emitting Materials

Acoustic Performance

Option 1 Speech Privacy, Sound Isolation, and Background Noise

Option 2 Acoustical Finishes and Site Noise

As ASC Steel Deck continues its green journey, we are committed to continuous improvements in our manufacturing processes, supply chain optimization, and our leadership role as an industry partner and environmental steward. As green certification programs pursue next-generation green building strategies, ASC Steel Deck will be by their side, listening and proactively seeking green solutions.