[Photo: Ryland Hormel]

All Weather Insulated Panels offers state-of-the-art insulated metal panels that are energy efficient and attractive.

Download a PDF of this story.

Download a PDF of this story.

To learn more, visit All Weather Insulated Panels

Metal: It’s cold and it’s hard. But it’s versatile, too, and used to make energy-efficient, environmentally friendly insulated metal panels (IMPs) that are becoming more and more popular with commercial builders in North America—and not only for industrial warehouses or cold storage. European builders in new commercial construction projects incorporate IMPs about 50% of the time. While the U.S. lagged for years, new commercial projects are now using IMPs nearly 10% of the time, and experts say that number appears to be climbing.

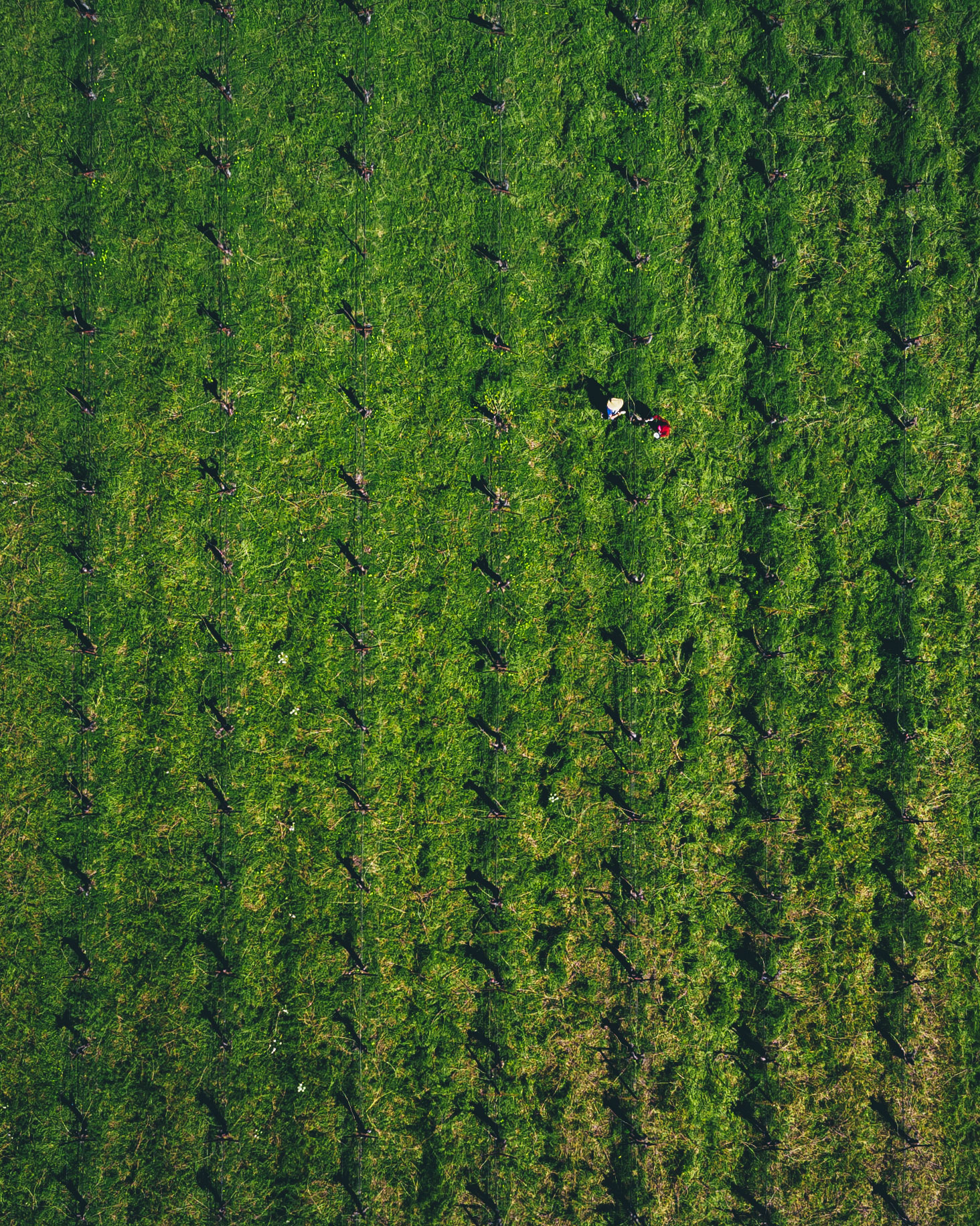

Over the last decade, All Weather Insulated Panels (AWIP) has emerged as a top manufacturer of IMPs, with an annual two-plant production capacity of around 30 million square feet to meet the needs of its burgeoning customer base. Those customers, including retail centers and more than 100 wineries, increasingly want a product that’s aesthetically pleasing—a product that offers better insulation and comes with a modish and inviting facade. AWIP is giving them precisely that.

“We’ve continued to develop new wall and roof products over the years, including wall surfaces like AdobeTexture [which has a knockdown stucco appearance] and our wood grain line,” says AWIP president and founder William Lowery. “We go out of our way to make a metal building look like something other than metal.”

More Uses and More Styles

For many years, IMPs such as those AWIP makes—closed-cell foam composite encased by two pieces of galvanized steel—were chiefly used to construct facilities that stored perishable foods at temperatures well below freezing. And they still widely serve that purpose. But in light of today’s rigorous energy and environmental standards for commercial buildings (including the California Public Utilities Commission’s Zero Net Energy goal for 2020), IMPs are uniquely suitable for a variety of other applications.

Venge Vineyards in California uses AWIP’s customized wall panels and HR3 roof panels for a distressed wood appeal.

[Photo: Ryland Hormel]

[Photo: Ryland Hormel]

In fact, AWIP believes its product rests in the “unique middle,” which is to say it provides savings in long-term energy savings, offers lower construction costs, and comes with high visual appeal that provides more architectural flexibility than ever before.

“We keep putting more and more products out there, and a lot of times it’s in response to what the customers are asking for,” says AWIP National Marketing Director Christopher Marchetti. “As an example, there has been high demand for a ‘ribbed’ or corrugated look, which is the next product we’ll be putting out.

[Photo: Ryland Hormel]

We can do the ‘modern, sleek’ look, but there’s a growing demand for non-metal appearance. It’s also easy to add to our panels to provide the desired appearance to meet the design requirements. We love to work with projects that make us find new solutions and textures for our customers.”

“We’ve worked with AWIP on many projects over the past decade,” says Vince Free, project manager for SubZero Constructors, one of the largest IMP contractors in North America. “Not only are they committed to superior customer service, we’re also seeing more high-quality products from them. That gives us and our clients greater design versatility, which really helps.”

Exciting Projects

Among AWIP’s recent and ongoing projects—including 10 more wineries, Whole Foods grocery stores, and even a dental office—perhaps the most intriguing is its early-stage work with aerospace research and development firm Blue Origin. If someday you find yourself watching a blastoff of one of its commercial spaceships, you’ll know the vehicle was assembled in a building protected by AWIP-made cladding and

fire panels.

“We can do the modern, sleek look, but there’s a growing demand for non-metal appearance.”

Christopher Marchetti, AWIP National Marketing Director

Of course, extraordinary products require extraordinary people, and Lowery is rightly proud of the highly trained team that meticulously oversees AWIP’s panel-crafting processes. “Suffice it to say that continuous line IMP production requires some unique skills that are not necessarily common to other industries,” he says. “Our trained operators are tasked with maintaining exceptional best practices in quality control. We really stress limiting scrap levels so we can maximize our resources. That means our foam composite formulas have to be spot-on, and that requires a deep understanding of the chemistry in our manufacturing process. It’s not that difficult to make a lot of panels, but it is a challenge to maintain the high quality our customers expect in every panel.”

With AWIP and its ever-expanding line of panels leading the way, Lowery envisions a future in which IMPs are the construction standard for every commercial project in North America. Because when it comes to securing a building’s thermal envelope, he says, referring to an all-in-one air, water and vaper barrier. “Nothing is better.”

And, thanks to AWIP’s stylish innovations, better looking.

The wall panels are AWIP’s 5-inch DM40 panels with 22-gauge steel exterior, to which “board and batten” wood siding was applied using screws into the 22-gauge steel. They have an R value of 41. [Photo: Ryland Hormel]

[Photo: Ryland Hormel]

AWIP BY THE NUMBERS

R-50

The foam-insulated panels can reach above R-50

4–6

The panels can sway several inches during seismic activity

We can do the ‘modern, sleek’ look, but there’s a growing demand for non-metal appearance. It’s also easy to add to our panels to provide the desired appearance to meet the design requirements. We love to work with projects that make us find new solutions and textures for our customers.”

“We’ve worked with AWIP on many projects over the past decade,” says Vince Free, project manager for SubZero Constructors, one of the largest IMP contractors in North America. “Not only are they committed to superior customer service, we’re also seeing more high-quality products from them. That gives us and our clients greater design versatility, which really helps.”

Exciting Projects

Among AWIP’s recent and ongoing projects—including 10 more wineries, Whole Foods grocery stores, and even a dental office—perhaps the most intriguing is its early-stage work with aerospace research and development firm Blue Origin. If someday you find yourself watching a blastoff of one of its commercial spaceships, you’ll know the vehicle was assembled in a building protected by AWIP-made cladding and

fire panels.

Of course, extraordinary products require extraordinary people, and Lowery is rightly proud of the highly trained team that meticulously oversees AWIP’s panel-crafting processes. “Suffice it to say that continuous line IMP production requires some unique skills that are not necessarily common to other industries,” he says. “Our trained operators are tasked with maintaining exceptional best practices in quality control. We really stress limiting scrap levels so we can maximize our resources. That means our foam composite formulas have to be spot-on, and that requires a deep understanding of the chemistry in our manufacturing process. It’s not that difficult to make a lot of panels, but it is a challenge to maintain the high quality our customers expect in every panel.”

With AWIP and its ever-expanding line of panels leading the way, Lowery envisions a future in which IMPs are the construction standard for every commercial project in North America. Because when it comes to securing a building’s thermal envelope, he says, referring to an all-in-one air, water and vaper barrier. “Nothing is better.”

And, thanks to AWIP’s stylish innovations, better looking.

Learn more about All Weather Insulated Panels and see related stories here.