Story at a glance:

- Industry leaders are changing the way we think about future design and manufacturing.

- Autex Acoustics is committed to a circular manufacturing and taking waste out of the waste stream.

- SOM promotes best practices for a resilient, carbon neutral built environment as part of its Climate Action Group.

“Show, don’t tell.”

That’s the mantra of Autex Acoustics Creative Director Jonathan Mountfort.

“Trying to tell someone something is less than 5% effective. If you turn up with a prototype or an example of how something might work, people stand up and take notice a hell of a lot quicker.”

Autex Acoustics is the living embodiment of that mantra, as its teams—from New Zealand to California—work to build examples of big ideas with urgency, capitalizing on excitement at a time when sustainable solutions are desperately needed. Their pelletization technology, which they brought to the US in 2024, is just one example. In 2025 Autex Acoustics set out to introduce Embrace to the US—an acoustic wall system of New Zealand strong wool and Abodo timber.

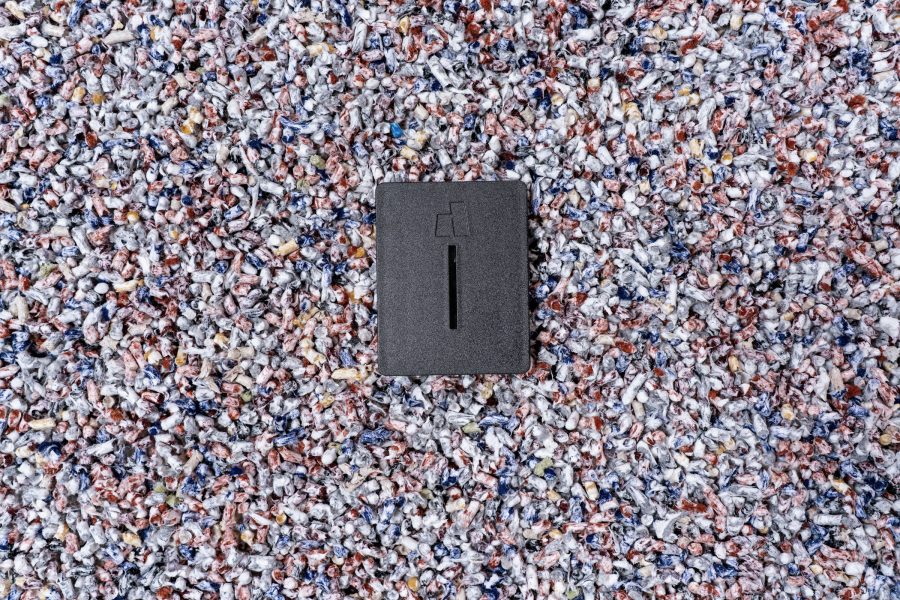

Autex Acoustics innovated the world’s first pelletizer on its journey to circular manufacturing when it couldn’t find a simple effective process already out there. “The thought behind the project was, if this textile has come from a solid material, then a truly circular product should be able to return to a solid material,” Mountfort says.

Because the product entering the Pelletizer is made of Autex Acoustics material already, solutions like the company’s SpinFix adhesive-free mounting systems or Frontier End Caps (accessories made from pelletized PET) can be recycled back through the pelletizer process alongside other PET products. “You’re mitigating impact,” Mountfort says. It’s hard to argue with ‘show, don’t tell.’ Naysayers can’t say ‘nay’ to a working example.”

Advancing the Mission

Autex Acoustics’ Frontier End Caps (made from pelletized PET) can be recycled back through the pelletizer process with other PET products. Photo courtesy of Autex Acoustics

Autex Acoustics has long been heavily invested in following cradle-to-cradle principles, but Mountfort likes to take that idea one step further, saying there is “no such thing as a sustainable material.” Instead, manufacturers like Autex Acoustics work to push the boundaries of what it means to be sustainable. That includes exploring how they can make solutions with as much recycled content as possible. “That’s what takes the waste out of the waste stream,” Mountfort says. “It goes from a single-use plastic bottle to a useful, humanity-serving acoustic panel.”

Even so, he notes the high turnover of interior design projects; companies turn over, offices remodel. It’s important, he says, that the recycling story doesn’t end there. “The ability to bring that material back, this is the next phase of what I’m starting to call the new industrial revolution. It’s bringing that material back to us and processing it into the next product, which if it’s from an acoustic panel it’s often into insulation or a backing.” That then goes into the very fabric of a building and can last 25 or even 100 years, Mountfort says.

Autex Acoustics came up with what Mountfort calls a “relatively simple process” of turning polyester acoustic panels, backings, or insulation materials into pellets. “We’re turning it straight into pellets from an acoustic panel, with slight modifications to the molding process. Now that material can go into any recycling scheme anywhere in the world that recycles PET, which is most countries. It puts it into a format that’s readily and easily recyclable, and from there the pathways open up.”

Mountfort says scaling each of those steps is not only very possible; it’s very economically viable. “The world’s proving it’s easy to create polyester acoustic panels and felts, and that’s a better place for it than clothing,” he says.

Rising to Meet Challenges

In April 2025 Autex Acoustics launched its Autex Future Lab, a team within Autex that includes people across sustainability, science, manufacturing, design backgrounds, and more—all on a mission to find and develop the best materials for a more sustainable future.

Manufacturers aren’t the only ones driving innovation. Architects, too, are stepping up. In 2022 Skidmore, Owings, & Merrill (SOM) became a carbon-neutral business through emissions reductions and carbon offsets. Even earlier, in 2017, they founded a Climate Action Group (CAG), putting climate action at the center of their practice. “It signaled a shift from sustainability as an add-on to a firmwide ethos, ensuring every project and every operation is aligned with a zero carbon, resilient future,” says Chris Cooper, design partner at SOM.

The CAG leans on the collective expertise of the firm’s interdisciplinary practice to develop and promote best practices for a resilient, carbon neutral built environment. The group collaborates with SOM’s Sustainable Engineering Studio (SES) to share knowledge and implement high-impact and holistic strategies, Cooper says. They are targeting net zero operational carbon for 100% of their active work by 2030 and net zero whole life carbon for 100% of active work by 2040. “We evaluate 100% of projects for embodied and operational carbon and conduct annual internal design reviews to inform our design process and ensure each project is moving toward these goals. We also evaluate our internal operational carbon,” Cooper says.

Creating consistent, high-performing sustainability strategies that also respond to local context remains a central challenge.

He says scaling meaningful impact across diverse geographies and regulatory frameworks is the industry’s biggest challenge. “Different regions have different climate priorities, building codes, and economic conditions where contextual priorities can often pull decisions in opposing directions. True progress requires a unifying framework that allows local solutions to thrive while contributing to global climate goals. Creating consistent, high-performing sustainability strategies that also respond to local context remains a central challenge.”

He says while many organizations have adopted bold climate commitments, the industry often struggles to operationalize them at the speed and scale required. “Delivering on net zero pledges requires new financial models, procurement pathways, and stronger collaboration across the value chain. Without accelerating delivery, today’s promises risk becoming tomorrow’s missed opportunities.”

The materials supply chain—responsible for significant carbon impacts—is also a big need and remains fragmented and opaque, Cooper says. “Decarbonizing what we build with is as critical as how we design and operate buildings. Achieving transparency and transformation here is one of the greatest hurdles.”

Fortunately he says conversations around sustainability have largely moved away from considering it an “add-on” to recognizing it as a fundamental responsibility of the profession. “We have moved from energy efficiency checklists toward holistic approaches that consider carbon, health, equity, and resilience together,” Cooper says. “The industry stands at a turning point. We have the tools, knowledge and precedents to deliver highly sustainable, high-performing projects, yet systemic inertia, fragmented regulations, and uneven adoption still prevent uniform progress.”

He continues: “The future will demand integration and acceleration, from material circularity to AI-driven design optimization and large-scale renewable integration. Architects will increasingly act not only as designers but also as systems’ thinkers and climate strategists, collaborating with clients and communities to deliver transformative outcomes.”

A Regenerative Future

Embrace strong wool rolls are seen here inside the Autex Acoustics Future Lab. Future Lab is a collection of manufacturers, scientists, product designers, architects, and primary producers working together to create innovative material solutions. Photo courtesy of Autex Acoustics

Autex Acoustics’ new showroom in Los Angeles celebrates its creative and sustainable spirit. Their Frontier baffles, seen here, include End Caps made from 100% recycled PET. Photo courtesy of Autex Acoustics

Mountfort is hopeful, pointing to regenerative agriculture as another solution. “Regenerative agriculture is delivering fantastic environmental outcomes like nothing else we’ve ever seen,” he says.

Building agriculture around soil health and biodiversity delivers great outcomes and provides massive scale opportunities for future fiber, food, and building products, Mountfort says. “It’s not one single business; it’s a web of interconnected smaller businesses. The opportunities there literally make my skin tingle.”

We have the recipe for reversing climate change, he says. “Look after the soil, scale the regenerative practice, and ‘decertify’ ruined arable and nonarable land by adopting regenerative agricultural practices, whether it be animal- or plant-based. From that there’s a wealth of different fiber opportunities for us to use—wool, hemp, cotton, linen, flaxes—all of these different opportunities sit there to clothe people, to build buildings, to sequester carbon,” Mountfort says. “There are so many projects out there now doing such good work in this space; it’s very hard to dismiss.”

That also creates opportunities for a new industry, Mountfort says, and to eliminate the concept of waste, envisioning the output of one product cycle as the beginning of the next. “We can live in abundance. We can have lots and lots of people living in step with nature,” he says.