Story at a glance:

- Thermory has fine-tuned the thermal modification process using steam to have more control.

- Thermory’s thermally modified ash is rot-resistant for a minimum of 25 years.

- Modified wood mimics the qualities of tropical species without deforestation or the use of plastics or chemicals.

Imagine taking beautiful real wood with all its natural qualities and using steam heat—no chemicals—to enhance every fiber, making it rot- and moisture-resistant. Combine that process with careful sourcing, and you have a product that is “as close to perfect as it gets for our planet,” says Kevin DeMars, part-owner of Thermory USA.

DeMars and co-owner Mark Challinor brought Thermory’s, an international company based out of Estonia, thermal modification methods and practices to the US a decade ago. The decision was obvious for DeMars, who had been purchasing wood products in his previous position for years. Several random occurrences kept him questioning, “What is up with this ‘cooked wood?’”

You could say it was meant to be. “I thought, ‘Here is a product that works and works well in Europe, but no one knows about it in North America.’ People were dabbling, but it had been terribly unsuccessful. I saw this as a unique opportunity to introduce this product in the right way. We could create it correctly and teach people how to use it correctly,” he says. The rest is history. “We now have our own category in the building industry.”

Photo by Ryoma Tominga

Thermory’s founders—Marko and Meelis Kajandu—fine-tuned the thermal modification process. They were unhappy with the standard methods and chambers of the time, so they went deep into the science. The result is a process that involves both heat—altering the wood to enhance its longevity and make it both rot and moisture resistant—and steam—allowing for complete control over the process. It all takes place in 20,000-square-foot chambers for consistency and perfection with every board.

Thermory engineers and scientists are just beginning. They are constantly evolving processes and equipment to make thermally modified wood better. DeMars shared with gb&d some of the many ways thermally modified wood enhances designs while keeping sustainability front and center.

How does the thermal modification process work?

Think of a maple tree. It is full of carbohydrates and sugar that are a food source for mold and fungus. What we do is eliminate the sugar in the wood, basically removing that food source. There is nothing for mold and fungus to latch to, making the wood rot-resistant.

The heat also alters the cellular structure—composed mostly of carbohydrate chains—in a way that causes it to lose the vacuum effect that pulls water through the wood. That is what makes the wood moisture-resistant.

The whole process takes just a couple of days. There are lots of parts that make up the wood. We know exactly at what temperature one cellular component is altered versus another. We can change a specific part of the wood without altering another, allowing it to maintain its structural integrity. It is what sets us apart from other domestic producers of thermally modified wood.

How is thermally modified wood a sustainable choice?

There are no chemicals or plastics used in the process, just heat and steam. It takes minimal energy as the process only takes a couple of days, versus kiln-drying that can take several weeks. And it is biodegradable in its life cycle. It is still wood. It is as close to perfect as it gets for the planet.

At Thermory, we are careful with how we source our wood. We have taken great care to understand how different forests and environments renew. We source from several locations around the world and make sure to leave all forests healthy and thriving. We never source from rainforests. Since our process makes the wood rot-resistant and stable we can source wood from the Northern Hemisphere. It mimics the qualities of tropical wood without deforestation or the use of plastics or chemicals like in pressure-treated or composite lumber.

Our product is thoroughly inspected before leaving our factories, ensuring each board is straight, smooth, and beautiful—reducing waste. Sustainable practices are very important to us at Thermory. That is why we always consider transportation. We use ocean freight and rail whenever we can. It is highly efficient. We burn factory waste and recycle.

How does thermally modified wood bring design visions to life?

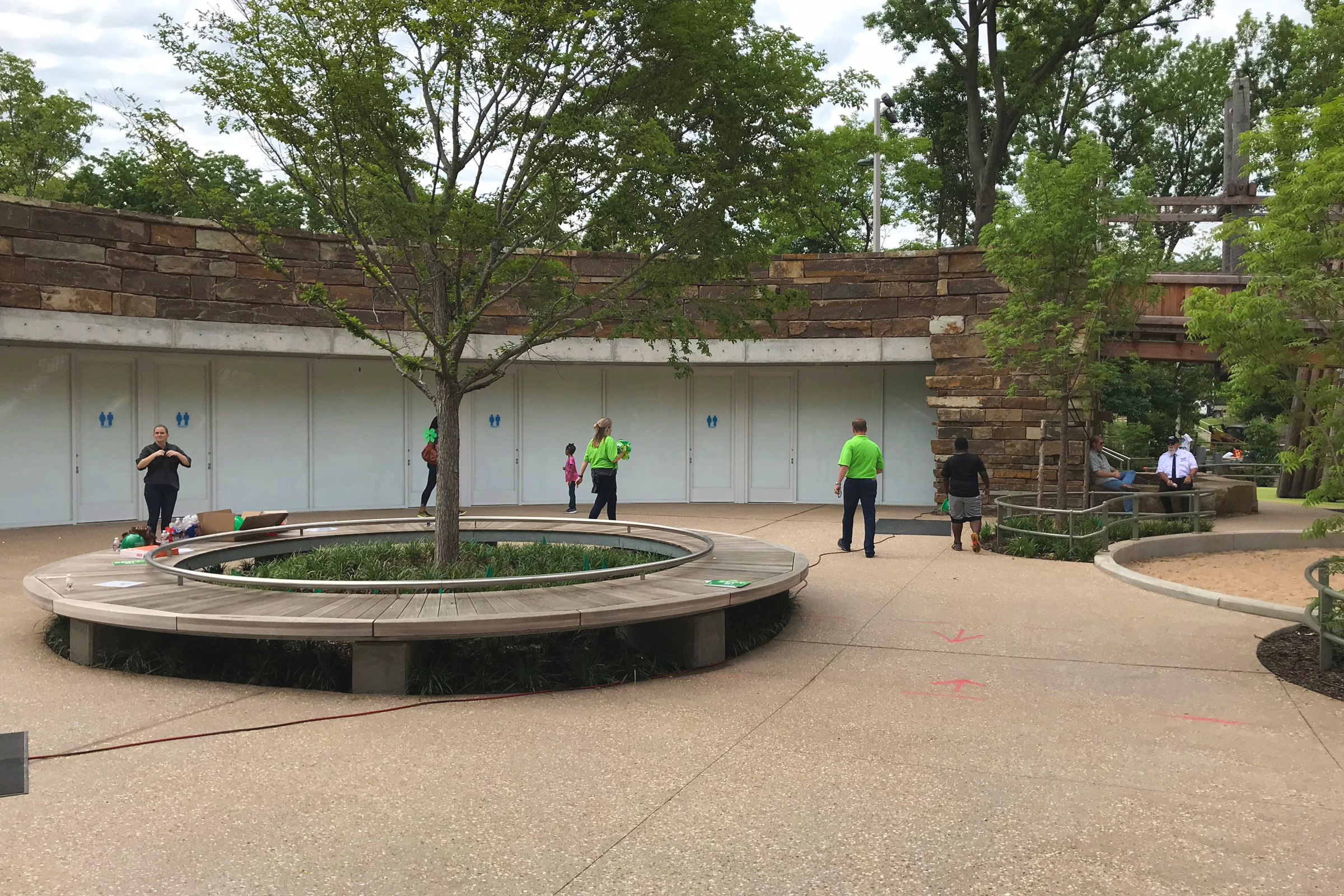

Designed by Michael Van Valkenburgh Associates. Photo by Ryoma Tominga

With the growing popularity of biophilic design, our product gives people better choices. It is ecological, beautiful, soft, and supple to the touch. The Gathering Place in Tulsa is the ultimate example of how our product can connect people in a sustainable and welcoming way.

Our Benchmark ash is used on benches, decking, and parts of playgrounds. The architects had a unique approach to their landscape architecture. They worked within the confines of the landscape itself and didn’t try to change it drastically. Our product is used to intermix lifestyle and landscape naturally.

We offer several different species of wood, sizes, and colors. We have textures that are brushed, rough, and smooth. Through our Ignite line, we offer a charred/cracked effect. Anything you want or need for a project, we likely have something cool. For the most part, our products are used on exteriors but there is no reason you can’t bring them inside. They have been used on ceilings or accent walls indoors.

How durable is modified wood and how is it maintained?

Without adding any extra oils or doing any special maintenance, our ash species is guaranteed to be rot-resistant for 25 years or more. It is a very durable wood, holding up to all types of weather and environments. It is strong, often used to make baseball bats and tool handles. It can definitely take some abuse.

Once it is correctly installed, you can keep it looking good by cleaning it off with a broom and oiling it once a year. Think about maintenance like taking care of your skin, just like sunscreen on your face. It is not the end of the world if you don’t put it on your skin, but it will look a lot older, a lot quicker. Keep it clean and oil it once a year, and it will perform exceptionally well.

What should architects consider when specifying a modified wood project?

The Gathering Place, Tulsa, OK. Photo by Ryoma Tominga

There are lots of great things you can do with our products, but it is still wood. It performs extraordinarily well, but it is not perfect and is not a solution for challenging installations. If used as decking, there must be some ventilation. Occasionally we will see an architect who chooses to keep a deck frame close to the ground, and there is no underdeck ventilation. If they choose to build close to the ground, there are some precautions they need to take. There needs to be proper ventilation and draining to increase the lifetime and performance of the deck.

It is important to design around the products you want to use rather than fitting the product into the design. A lot of times we have architects who specify boards that are 16-foot lengths. We are using a northern species, and with hardwoods you typically don’t get the lengths you get with other species.

We try to be careful about the attributes we communicate. For example, the modified boards are moisture-resistant, but some people hear “waterproof” and think they can install them at the bottom of a pool. We recommend that architects learn about our product and design around those specifications.

What are some common misconceptions about thermally modified wood products?

They are all created equal. You might have a bad experience at a restaurant, but that doesn’t mean all restaurants are terrible. It depends on where you get it and who makes it. Modified wood in the US is still in its infancy, and proper modification is difficult and tedious. Our equipment is highly advanced, and the scientists who run it are widely intelligent in the field of wood science.

A common remark we get is that thermally modified wood is brittle. In comparison to other woods, yes, but extreme brittleness is not indicative of the science in general—it has a lot to do with who is modifying the wood. Extreme brittleness usually means it has been cooked too hot and not modified correctly.