Story at a glance:

- The fourth generation of LEED takes a comprehensive approach to water efficiency.

- The common commode is responsible for more than 30% of indoor water usage.

- Choose from three major types of flushing technologies: gravity, pressure-assist, and vacuum-assist.

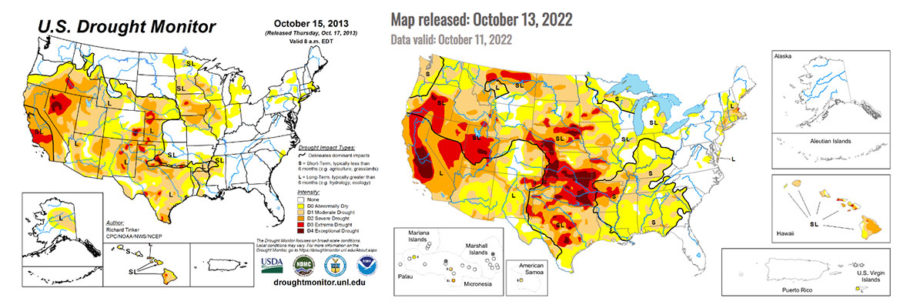

Conservation has gone from being a simple buzzword to a critical sector of the design and building phase of new construction. Just by looking at these screenshots from the US Drought Monitor, comparing the last 10 years and the progression of drought, it’s plain to see that we have a huge problem on our hands.

A closer look at the US Drought Monitor. Image courtesy of Niagara

To combat this our government offers grants and tax relief programs to help encourage builders to utilize water conservation in their plans. Builders and developers must meet sustainability prerequisites set forth by various verification systems to be eligible. As you probably already know, the LEED program is the most popular third-party green building verification system. LEED-certified buildings are not only more efficient than their predecessors, but they are eligible for numerous tax breaks and credits as well.

The fourth generation of LEED certification standards is focused on a better user experience, new materials, a performance-based methodology, and a comprehensive approach to water efficiency that evaluates total building water use. Engineers and architects who are tasked with designing green buildings should be aware that LEED V4 has doubled down on the importance of water protection. For example, earlier versions of LEED awarded a point for a 20% reduction of water usage below previous levels, but the new version makes the 20% reduction a prerequisite. This shift signals a clear acknowledgment of the growing importance of freshwater control.

So how can plumbing and mechanical engineers tasked with water efficiency take steps to ensure their next green building significantly reduces energy costs and is eligible for LEED V4 certification? Realizing just how dramatically the scope of the water efficiency segment has been expanded is a necessity.

Water Use in LEED V4

Photo courtesy of Niagara

Previous versions of LEED certification were primarily concerned with fixtures and fittings. V4 has broadened the new conditions to include all possible water use categories. The Total Building Water Use for New Building Construction and Design considers processes, cooling towers, outdoor water, rainwater management, and ongoing building metering requirements. This means engineers and architects must account for the entire life cycle of their building’s water use.

Not everyone can utilize a gray water system, and surprisingly the common commode is responsible for more than 30% of indoor water usage. It’s been proven that if a property switches to high-efficiency models, more than 4,400 gallons of water can be saved annually, and there have even been cases where it can cut water usage by more than 55% even in older buildings.

The EPA WaterSense Program

The second drastic change to LEED V4 is the requirement to employ products that have been certified under the EPA WaterSense Program. The WaterSense Program is a voluntary US Government sponsored program that is designed to change the market for water-efficient products. To qualify for WaterSense labeling, products must provide water savings, increased performance, various technological options, measurable results, cost-effectiveness, and energy differentiation.

WaterSense-certified toilets, for example, must use 1.28 gallons per flush or less. This 1.28 GPF rule qualifies certain fixtures for the toilet water efficiency credit category in LEED V4.

Smarter Products

Niagara toilet. Photo courtesy of Niagara

As water efficiency continues to grow in importance, it will be necessary for engineers to find products that can support new green building codes from the outset. LEED V4 toilets should operate at or under 1.28 GPF, and it’s recommended to go even lower in GPF due to the consistent updates to water restrictions.

One of the biggest decisions you’ll have to make regarding the plumbing is choosing the right toilet for the property and client type. Here are a few quick basics to consider:

- GPF should be the first feature to consider since it’s the most relevant to LEED V4. GPF, or Gallons Per Flush, is a measurement of how much water is used each time the toilet is flushed.

- LEED V4 requires products to be WaterSense certified, which again means they must be at 1.28 GPF or lowers. Thanks to decades of innovation, the ultra-high-efficiency toilets on the market today are some of the best-performing toilets available.

- Depending on how efficient you want to go, you’ll want to also consider the type of flushing technology the model you specify has. There are three major types of flushing technologies on the market: gravity, pressure-assist, and vacuum-assist.

Traditional Gravity-Fed Technology

When opening the lid of a toilet’s tank, you will likely find a gravity-fed technology system. Most commonly you will come across a toilet that utilizes a flapper.

For a toilet that uses a flapper, when the toilet is flushed a rubber flapper is lifted, allowing gravity to force fresh water from the tank into the bowl, pushing waste down the trapway and into the drain system. A fill valve then refills the tank for the next use.

This technology, while common, does present several maintenance headaches:

- The chain attached to the flush lever can become tangled or weakened, preventing flushing entirely.

- The rubber flapper can deteriorate or become unseated over time, creating a leak that causes the fill valve to continuously feed water into the tank.

- The fill valve can become misaligned or worn, causing the tank to not refill.

The challenges of maintaining a traditional gravity-fed toilet throughout its lifetime have made many plumbing professionals look into other toilet technology options that offer more consistent performances as well as a flush that uses less water.

Pressure-Assist Technology

As the name implies, pressure-assist toilets use highly pressurized air to evacuate the bowl and push waste through the trap. These toilets use a specialized chamber within the tank that is used to create the air pressure.

Toilets equipped with pressure assist technology are highly efficient at clearing away waste and preventing clogs, which is vital for high-traffic commercial and industrial applications that need a clean, unclogged toilet for each use, as downtime or an unsightly appearance can impact the overall satisfaction of a customer or employee’s experience.

These toilets also feature a larger water spot, ensuring there is no waste buildup on the side of the toilet bowl. Pressure-assist toilets are louder than other toilet technology types due to the forced air used to evacuate the bowl. These models are also typically more expensive than other options because of the cost of the pressure-assist vessels in the tanks. Due to this, they are rarely found in residential or other low-traffic applications.

Vacuum-Assist Technology

Many jobs or projects need to balance both power with water efficiency when it comes to toilets. Vacuum-assist toilets provide both. Upon flushing the water exiting the specialized chamber within the tank creates a vacuum, depressurizing the trapway and allowing waste to be pulled through the trap. This allows vacuum-assist toilets to use substantially less water. Many vacuum-assist toilets meet EPA’s stringent WaterSense certification requirements and achieve a MaP Premium certification, highlighting the efficiency and power of these toilets. Some models even use as little as 0.8 GPF, offering maximum water savings.

Vacuum-assist toilets are becoming favored in a variety of applications for several reasons. The chamber within the tank eliminates the moving parts found in traditional toilets, significantly reducing required maintenance from worn-out or unseated components. Plus, the fill valve remains submerged, reducing the noise heard during refill and creating a whisper-quiet flush. But the powerful quiet flush paired with efficient water use is typically the main decision driver. With no change in customer use, a powerful flush is achieved while reducing the amount of water used, creating remarkable cost savings throughout the life of the toilet.

Drainline Carry

Regardless of the type of flush technology you decide to specify, be sure to consider the model’s tested drain line carry. Drain line carry refers to the distance that a toilet can move waste down the drain line. A toilet with poor line carry will cause plugs in the line. Under ASME A112.19.2, a toilet must move waste down a drain line of at least 40 feet. Testing is done by third parties such as the IAPMO to ensure results are unbiased and accurate.

Code Considerations

Image courtesy of Niagara

In addition to worrying about conserving water, professionals in the plumbing space must also be concerned about staying up to code. This is why Niagara—a leading manufacturer in water efficient, high-performance products—developed its newest Continuing Education (CE) course, The Benefits of Implementing Water Conservation Standards by Building Beyond Code. This informative course helps professionals become experts in current global water usage and standards, water efficiency requirements in building codes and standards, how to upgrade specifications for efficiency, and how to specify products that are beyond code regulations.

This course teaches how to significantly reduce water consumption and costs by using ultra-high-efficiency toilets, capitalize on green building benefits by lowering water consumption, and how to inform developers on financial incentives related to water conservation for affordable housing programs.

The course also reviews how to optimize the benefits available from exceeding the current code and standard water consumption requirements. Those who have taken the course will be able to choose water-efficient products with confidence and impress clients with their suggestions.

The need for a course like this is imperative, as the new infrastructure bill provides substantial funding for green building programs. For those who work directly with homeowners, rebate programs can help reduce the price for sustainable choices. Pricing can be one of the largest reasons a homeowner may want a more traditional product that can be a water waster, but it’s important to take all the financial benefits that come from using water-conserving products into account—like lower water bills, utility rebate programs, and LEED points.

The 2021 US Municipal Water & Wastewater Utility Rate Index showed that the combined water and wastewater bill has increased by 43.2% since 2012. Water and sewer rates alone can be a significant part of a property’s utility bills, and there have been case studies as recent as 2021 that prove the use of installing products that use as little as 0.8 GPF can save properties, especially multifamily properties, thousands of dollars on utility bills. The key is to use products that have the EPA’s WaterSense, MaP, or even better, MaP Premium certifications. Those certifications, combined with the right flushing technology, can guarantee performance in drainline carry, little to no clogging, and customer satisfaction.

For those concerned with using low-flow products because of drainline carry, don’t forget that each product does not act on its own to push waste to the sewer line. In the example of a toilet that can use as little as 0.8 GPF, the water being flushed to clear the bowl and push waste through the trapway just has to get the waste to the downline. At that point, other activities like washing hands, taking a shower, or even running the dishwasher will all culminate in pushing collective waste down to the sewer. So while using a higher GPF toilet could get the job done, it’s unnecessarily wasteful.

Toilets are only the beginning, though. LEED V4 is a comprehensive new approach to water conservation, and new building designs will have to shift their focus on water efficiency from an afterthought to the design pillar.