Story at a glance:

- The Delaware Memorial Bridge deck project uses ultra-high-performance concrete (UHPC).

- Resilience-centered design and materials like UHPC can minimize disruption, maximize durability, and support sustainability and hazard adaptation.

- The Delaware project builds resilience into infrastructure.

In the evolving dialogue around sustainable construction, the industry is shifting from a carbon-only lens to a broader understanding that resilience is not optional; it is essential. The Delaware Memorial Bridge deck rehabilitation project is a clear demonstration of this shift. By prioritizing long-term performance, reduced disruption, and adaptive material technologies, the project exemplifies how resilience is not just a goal, but a deliverable. Resilience should become the new standard for sustainable building.

A Bridge Under Pressure

The Delaware Memorial Bridge, a critical pair of twin suspension spans connecting Delaware and New Jersey, supports more than 80,000 vehicles daily. Originally opened in 1951 and 1968, the structures had withstood decades of service. In 2022 it was clear that the northbound deck needed rehabilitation to prevent structural degradation and extend service life.

This posed a resilience challenge: how to execute long-lasting major repairs without compromising the bridge’s structural integrity or significantly disrupting traffic and toll revenue while incorporating climate mitigation and adaptation measures.

Constraints Meet Innovation

Photo courtesy of Chryso

Traditional repair methods often demand extended construction timelines, heavier materials, and repeated maintenance, without accounting for the global warming potential of repair materials or the increasing risks posed by climate-related hazards. The Delaware River & Bay Authority instead selected Ultra-High Performance Concrete (UHPC) for its durability, lower required thickness, and long life cycle performance.

UHPC provided a structural overlay, just three inches thick, that would both protect and strengthen the aging deck. This fiber-reinforced concrete delivers compressive strengths exceeding 18,000 psi, more than three times stronger than standard bridge deck concrete, and offers a longer service life than conventional overlays.

Material Solutions for Resilient Outcomes

To further tailor the UHPC for the project’s extreme requirements, Chryso North America supplied advanced admixture technologies that optimized workability, rheology, placement, and curing time. The admixtures allowed contractors to comply with the project requirements, resulting in denser, more durable concrete.

Notably, the admixtures enabled the UHPC to be paved in a downhill direction, a rare capability in bridgework, which allowed the contractor to accelerate the construction schedule significantly.

Execution: Speed Without Sacrifice

The third and final phase, completed in 2023, involved milling off two to three inches of deteriorated deck and installing an equivalent UHPC overlay. The team installed more than 5,000 cubic yards of UHPC using a custom-designed paver and later diamond-ground the surface for smoothness.

This resilience-centered method shaved two weeks off the anticipated 11-week construction window in Phase 3, demonstrating that resilient design can go hand-in-hand with efficiency.

Environmental and Economic Resilience

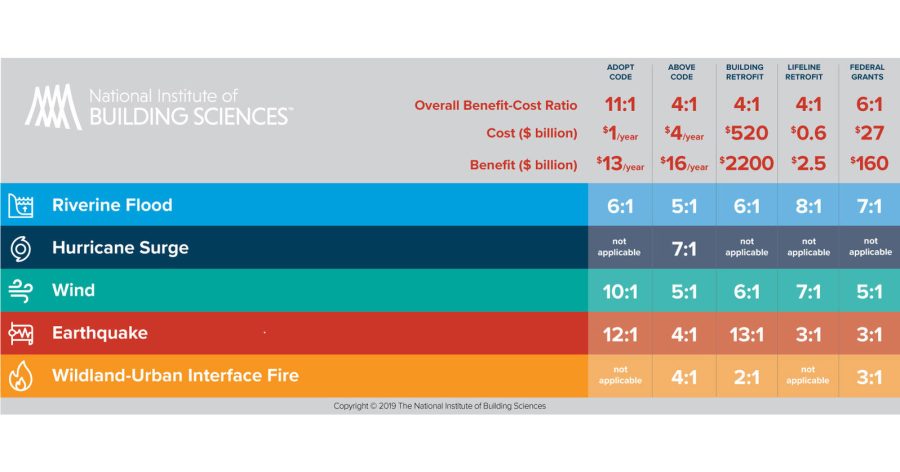

Chart by the National Institute of Building Sciences, courtesy of Chryso

The resilience benefits extended beyond structural strength and durability. Because UHPC requires thinner application, total material volumes were reduced, lowering the project’s embodied carbon. Fewer replacements over the bridge’s lifetime mean fewer emissions from repair cycles, a crucial consideration in the broader context of life cycle carbon accounting.

These long-term savings align with the insights of the National Institute of Building Sciences. According to their “Mitigation Saves” 2024 study, lifeline infrastructure retrofits like upgrades to power, water, telecommunications, and transportation systems yield a $4 return for every $1 spent on resilient infrastructure. The cost to benefit ratio can be much higher depending specifically on what type of natural disaster the project is mitigating for, as seen in the chart above. Strengthening these lifeline infrastructures against hurricanes, floods, fires, and other hazards significantly reduces future disaster recovery costs.

Recognition and Blueprint for the Future

In October 2024 Engineering News-Record honored the Delaware Memorial Bridge project with its 2024 Mid-Atlantic Regional Best Project Award in the highway/bridge category. More than a recognition of innovation, the award validates resilience as a practical and high-performance benchmark.

“The future of UHPC in construction is bright,” says Steven Williams, president of construction chemicals, infrastructure, and commercial for Saint-Gobain North America. “The greater strength with less material needed and longer service life of more than 50 years makes UHPC a key component in the sustainability goals of the construction industry. The use of UHPC on the Delaware Memorial Bridge deck rehabilitation project was the perfect fit, offering speed and lightweight durability. We were pleased to apply our admixture technologies to customize the UHPC so that it met all performance needs and ensure that it will stand the test of time.”

Resilience in Action

As I have previously written, resilience must be the next benchmark in sustainable building, infrastructure, and superstructure construction—a necessary counterbalance to carbon-focused strategies. The Delaware Memorial Bridge is proof that this shift is already underway. Resilience is no longer a theoretical ideal. With the right materials, partnerships, and planning, it’s being built into our infrastructure now.

Chryso North America is proud to help lead this transformation. By aligning with evolving stakeholder priorities, especially those of architects and engineers seeking actionable resilience strategies, we are committed to delivering high-performance solutions that meet technical demands and address broader societal and environmental concerns. Insights from today’s resilience measurement tools reveal clear gaps in education, resources, and implementation, gaps that Chryso is actively working to close through collaboration, innovation, and knowledge sharing.

As resilience continues to move from concept to construction site, Chryso remains at the forefront, partnering across disciplines to build infrastructure that’s ready for the future.